Metamorphosis - Cruise Ship Portal

Metamorphosis - Cruise Ship Portal

Metamorphosis - Cruise Ship Portal

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Insight> Bunker fuels<br />

There is no doubt that reducing<br />

emissions is a crucial factor in<br />

cruise operations today. While<br />

emitting fewer pollutants into the<br />

environment should be motivation in itself, for<br />

operators the main driver in recent years has<br />

been the rising cost of fuel.<br />

However, according to Sauli Eloranta,<br />

STX Europe’s vice-president of product<br />

development and innovation, cruise and<br />

ferries, the tough economic conditions<br />

have helped the environmental cause.<br />

“The high cost of fuel has always been a<br />

concern for the cruise industry: the less<br />

fuel consumed the better the results for<br />

the cruise lines, and the more value they<br />

can give their passengers,” he says.<br />

“<strong>Cruise</strong> ship energy management today is<br />

developing with greater emphasis on<br />

operational cost efficiency.”<br />

102<br />

Implementing technologies to reduce<br />

emissions is expensive and, in a tough<br />

economy, cruise lines understandably<br />

want to keep expenditure to a minimum.<br />

But streamlining operations can result in<br />

the added bonus of keeping costs and<br />

emissions at low levels. “<strong>Cruise</strong> lines are<br />

responding to the downturn by improving<br />

their cost efficiencies where they can and<br />

this, in turn, is leading to less energy<br />

being used,” says Eloranta.<br />

Back to the drawing board<br />

For shipbuilders such as STX Europe, the<br />

most effective way that operators can<br />

improve efficiency and reduce emissions<br />

begins at the drawing board.<br />

“When looking to reducing emissions,<br />

many people focus on technical solutions,<br />

but the most effective way is to start at<br />

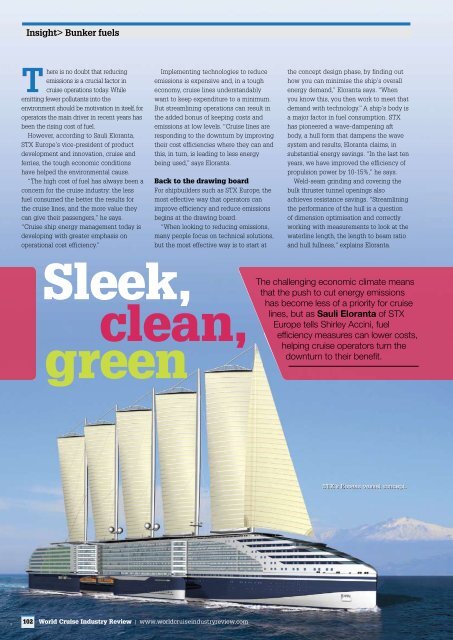

Sleek,<br />

clean,<br />

green<br />

World <strong>Cruise</strong> Industry Review | www.worldcruiseindustryreview.com<br />

the concept design phase, by finding out<br />

how you can minimise the ship’s overall<br />

energy demand,” Eloranta says. “When<br />

you know this, you then work to meet that<br />

demand with technology.” A ship’s body is<br />

a major factor in fuel consumption. STX<br />

has pioneered a wave-dampening aft<br />

body, a hull form that dampens the wave<br />

system and results, Eloranta claims, in<br />

substantial energy savings. “In the last ten<br />

years, we have improved the efficiency of<br />

propulsion power by 10-15%,” he says.<br />

Weld-seam grinding and covering the<br />

bulk thruster tunnel openings also<br />

achieves resistance savings. “Streamlining<br />

the performance of the hull is a question<br />

of dimension optimisation and correctly<br />

working with measurements to look at the<br />

waterline length, the length to beam ratio<br />

and hull fullness,” explains Eloranta.<br />

The challenging economic climate means<br />

that the push to cut energy emissions<br />

has become less of a priority for cruise<br />

lines, but as Sauli Eloranta of STX<br />

Europe tells Shirley Accini, fuel<br />

effi ciency measures can lower costs,<br />

helping cruise operators turn the<br />

downturn to their benefi t.<br />

STX’s Eoseas vessel concept.