H51308-v0A Manuale Istruzioni VTNC - Rhoss

H51308-v0A Manuale Istruzioni VTNC - Rhoss

H51308-v0A Manuale Istruzioni VTNC - Rhoss

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

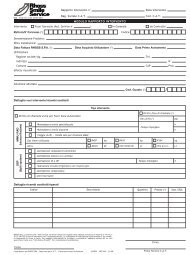

SECTION II: INSTALLATION AND MAINTENANCE<br />

If there is still a gap between the frame and the false ceiling, it should<br />

be reduced by working on the brace nuts and lock nuts again:<br />

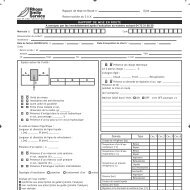

II.2.4 External renewal air and treated air outlet in<br />

an adjacent room (for models 60-85 only)<br />

The side openings made it possible to create a separate external<br />

renewal air inlet duct (5) and an air outlet duct in an adjacent room<br />

(6).<br />

Replace the grille:<br />

6<br />

5<br />

6<br />

5 External air inlet<br />

Air distribution in<br />

6<br />

adjacent room<br />

7 Polystyrene<br />

membrane<br />

7<br />

6<br />

5<br />

7<br />

7<br />

45°<br />

Replace the covers at the four corners of the frame, making sure that<br />

you secure the respective safety cords:<br />

II.2.3.4<br />

Checking the Correct Installation of the<br />

Frame-Grille Assembly (for all models)<br />

The frame must not show signs of deformity caused by excessive<br />

traction. It must be centred with respect to the false ceiling and, above<br />

all, it must guarantee an airtight seal between the air inlet and outlet.<br />

The figure shows the airtight seals (A-B), which prevent the air bypass<br />

(A) and treated air leakage (B) inside the false ceiling. After installing<br />

the assembly, check that the gap between the frame and the false<br />

ceiling is under 5 mm.<br />

Remove the external anti-condensation insulation, delimited by the<br />

punching, and remove the pre-cut sheet metal panels using a punch.<br />

Use a pencil to draw round the internal polystyrene (7), then cut it with a<br />

cutter, taking care not to damage the heat exchange coil behind it.<br />

II.2.4.1 Air Outlet in Adjacent Room (for models 60-<br />

85 only)<br />

An air outlet in an adjacent room requires the closure of at least the<br />

mouth corresponding to the duct using the specific kit KCB (blocking<br />

outlet mouths). An air recovery grille should be installed between the air<br />

conditioned room (where the unit is installed) and the adjacent room<br />

(near the floor if possible). Do not use the two pre-cut side openings on<br />

the unit at the same time.<br />

G<br />

W<br />

W D<br />

G<br />

W<br />

<strong>VTNC</strong><br />

D<br />

W Wall<br />

D Door<br />

G Grille<br />

W Wall<br />

D Door<br />

G Grille<br />

<strong>VTNC</strong><br />

max 5 mm<br />

G<br />

IMPORTANT!<br />

Do NOT use active carbon or electrostatic filter kits<br />

in the presence of ducts to the adjacent room.<br />

B<br />

A<br />

4-6 mm<br />

Use material suitable for operation at a constant temperature of 60 °C.<br />

The ducts may be made from flexible polyester (with a spiral steel core)<br />

or corrugated aluminium, clad externally with anti-condensation material<br />

(fibreglass of 12 ÷ 25 mm thick).<br />

Once installation is completed, the uninsulated surfaces of the ducts<br />

must be covered with anti-condensation insulation (for example,<br />

expanded neoprene of 6 mm thick).<br />

IMPORTANT!<br />

Failure to observe these instructions may cause<br />

dripping due to condensation. The manufacturer<br />

may not be held liable for any damage.<br />

41