ProMatic - Hormann.fr

ProMatic - Hormann.fr

ProMatic - Hormann.fr

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

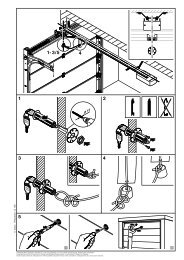

ENGLISH1)Unplug <strong>fr</strong>om the mains.2) Press the transparent button in the housing andkeep depressed.3) Insert the mains plug and keep the above-mentionedbutton depressed until the operator lighting flashes.If it only flashes once, the door data has beendeleted. You can then proceed with reprogrammingimmediately.NoteFurther signals <strong>fr</strong>om the operator lighting (flashes repeatedlyon inserting the mains plug) are explained in section 3.6.3.3.3.2 Programming the operatorDuring programming the travel path and the requiredforces for opening and closing are programmed or stored(data retained even in the event of a power failure).Before the operator can be programmed, the door datamust be deleted (see section 3.3.1) and the carriageengaged:1) If necessary, the disengaged carriage must be preparedfor engagement by pressing the green button (seefigure 19) on the carriage and the door must be movedby hand until the carriage engages in the belt lock.2) If necessary, insert the mains plug, the operatorlighting then flashes twice (see section 3.6.3).3) If necessary, use the DIL-switch "C" (accessible onremoving the operator cover, see figure 10 and 17) toset the desired behaviour of the closing door onapproaching the CLOSE end-of-travel position:- set DIL-switch "C" to OFF to change over to short"soft" stop for sectional doors (factory setting).- set DIL-switch "C" to ON to change over to long"soft" stop for up-and-over doors.4) Press the transparent button in the operator cover(see figure 20) ➜ the door opens with the operatorlighting flashing (OPEN learning cycle) and after reachingthe OPEN limit stop and a short reverse (approx.1 cm) comes to a halt with the operator lighting flashing.NoteIf the OPEN limit stop has not been reached, then theOPEN maximum force is set too low and must be increased(see section 3.3.3). After increasing the OPEN maximumforce (max. 1/8th turn per adjustment attempt), pressthe transparent button to cause the door to travel to theCLOSE end-of-travel position. Stop the door closingbefore it reaches the CLOSE end-of-travel positionby pressing the button again. Then repeat step 4 asexplained in section 3.3.2.5) Press the transparent button again (see figure 20) ➜the door closes with operator lighting flashing throughout(CLOSE learning cycle), in doing so the carriagemust reach the CLOSE limit stop. The operator thenimmediately causes the door (with operator lightingswitched on) to travel to the OPEN end-of-travel positionand the door then stays in this position. The operatorlighting goes out after 3 minutes.06.2004 TR10A014 RENoteIf the CLOSE limit stop has not been reached, then theCLOSE maximum force is set too low and must be increased(see section 3.3.3). After increasing the CLOSE maximumforce (max. 1/8th turn per adjustment attempt), deletethe door data (see section 3.3.1) and repeat the programmingprocedure.6) At least three uninterrupted travel cycles must beconsecutively carried out. In doing so, check that thedoor has fully reached its closed position (if not,readjust the CLOSE limit stop and re- programme theoperator). In addition, check that the door opens fully(the carriage comes to a halt shortly before reachingthe OPEN end-of-travel position).The operator is now programmed ready foroperation.7) Please check the programmed force limit by followingthe corresponding safety instructions provided in section3.6!3.3.3 Setting the maximum forcesThe required forces for opening and closing the doorwhich were learned and stored during programming areupdated also during the subsequent travel cycles. That'swhy in the event that the running action of the door getsincreasingly sluggish (e.g. spring tension slackens) it isimportant for safety reasons that these values do notreset themselves indefinitely, as otherwise any necessarymanual operation of the door could pose a possible safetyrisk (e.g. door could crash to the floor).That's why the maximum forces available for openingand closing the door are pre-set at the factory (potentiometerat intermediate setting) but these can beincreased if needed.The maximum forces set at the potentiometer have a slighteffect on the sensitivity of the force limit, since the forcesactually needed were stored during the learn cycle.The forces set at the factory are suitable for operatingmost standard doors.For setting the maximum opening and closing forces, apotentiometer is available for each direction, accessibleon removing the operator cover and marked P1 and P2(see figure 21.1 / 21.2).The maximum force in the OPEN direction can be limitedvia potentiometer P1; while the maximum force in theCLOSE direction can be limited via potentiometer P2.In doing so, turning clockwise increases the forces, whileturning anticlockwise reduces the forces.NoteIt is only necessary to increase the maximum forces presetat the factory (potentiometer at intermediate setting) shouldthe need arise during programming (see section 3.3.2).ATTENTION: Danger to life!Setting the potentiometer too high canresult in serious injuries!➤39