Bedienungsanleitung KXE - REITZ Ventilatoren

Bedienungsanleitung KXE - REITZ Ventilatoren

Bedienungsanleitung KXE - REITZ Ventilatoren

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

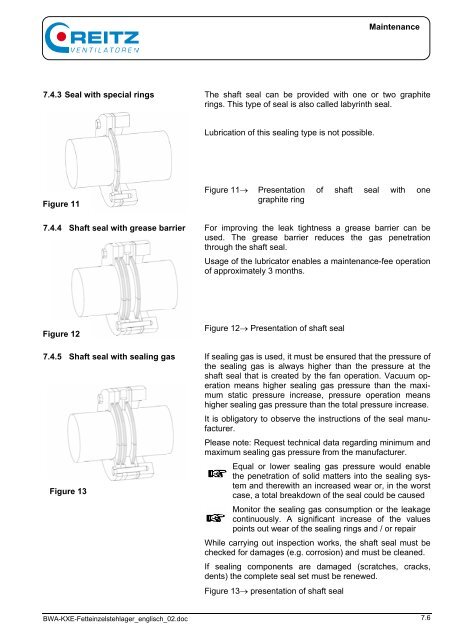

7.4.3 Seal with special rings<br />

Figure 11<br />

7.4.4 Shaft seal with grease barrier<br />

Figure 12<br />

7.4.5 Shaft seal with sealing gas<br />

Figure 13<br />

BWA-<strong>KXE</strong>-Fetteinzelstehlager_englisch_02.doc<br />

Maintenance<br />

The shaft seal can be provided with one or two graphite<br />

rings. This type of seal is also called labyrinth seal.<br />

Lubrication of this sealing type is not possible.<br />

Figure 11� Presentation of shaft seal with one<br />

graphite ring<br />

For improving the leak tightness a grease barrier can be<br />

used. The grease barrier reduces the gas penetration<br />

through the shaft seal.<br />

Usage of the lubricator enables a maintenance-fee operation<br />

of approximately 3 months.<br />

Figure 12� Presentation of shaft seal<br />

If sealing gas is used, it must be ensured that the pressure of<br />

the sealing gas is always higher than the pressure at the<br />

shaft seal that is created by the fan operation. Vacuum operation<br />

means higher sealing gas pressure than the maximum<br />

static pressure increase, pressure operation means<br />

higher sealing gas pressure than the total pressure increase.<br />

It is obligatory to observe the instructions of the seal manufacturer.<br />

Please note: Request technical data regarding minimum and<br />

maximum sealing gas pressure from the manufacturer.<br />

Equal or lower sealing gas pressure would enable<br />

the penetration of solid matters into the sealing system<br />

and therewith an increased wear or, in the worst<br />

case, a total breakdown of the seal could be caused<br />

Monitor the sealing gas consumption or the leakage<br />

continuously. A significant increase of the values<br />

points out wear of the sealing rings and / or repair<br />

While carrying out inspection works, the shaft seal must be<br />

checked for damages (e.g. corrosion) and must be cleaned.<br />

If sealing components are damaged (scratches, cracks,<br />

dents) the complete seal set must be renewed.<br />

Figure 13� presentation of shaft seal<br />

7.6