Hot Rolled Asphalt and Asphalt Concrete (Macadam) - Ministry of ...

Hot Rolled Asphalt and Asphalt Concrete (Macadam) - Ministry of ...

Hot Rolled Asphalt and Asphalt Concrete (Macadam) - Ministry of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

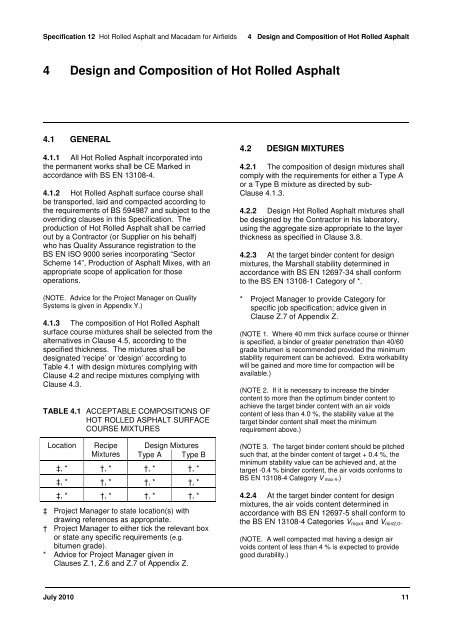

Specification 12 <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong> <strong>and</strong> <strong>Macadam</strong> for Airfields 4 Design <strong>and</strong> Composition <strong>of</strong> <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong><br />

4 Design <strong>and</strong> Composition <strong>of</strong> <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong><br />

4.1 GENERAL<br />

4.1.1 All <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong> incorporated into<br />

the permanent works shall be CE Marked in<br />

accordance with BS EN 13108-4.<br />

4.1.2 <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong> surface course shall<br />

be transported, laid <strong>and</strong> compacted according to<br />

the requirements <strong>of</strong> BS 594987 <strong>and</strong> subject to the<br />

overriding clauses in this Specification. The<br />

production <strong>of</strong> <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong> shall be carried<br />

out by a Contractor (or Supplier on his behalf)<br />

who has Quality Assurance registration to the<br />

BS EN ISO 9000 series incorporating “Sector<br />

Scheme 14”, Production <strong>of</strong> <strong>Asphalt</strong> Mixes, with an<br />

appropriate scope <strong>of</strong> application for those<br />

operations.<br />

(NOTE. Advice for the Project Manager on Quality<br />

Systems is given in Appendix Y.)<br />

4.1.3 The composition <strong>of</strong> <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong><br />

surface course mixtures shall be selected from the<br />

alternatives in Clause 4.5, according to the<br />

specified thickness. The mixtures shall be<br />

designated ‘recipe’ or ‘design’ according to<br />

Table 4.1 with design mixtures complying with<br />

Clause 4.2 <strong>and</strong> recipe mixtures complying with<br />

Clause 4.3.<br />

TABLE 4.1 ACCEPTABLE COMPOSITIONS OF<br />

HOT ROLLED ASPHALT SURFACE<br />

COURSE MIXTURES<br />

Location Recipe Design Mixtures<br />

Mixtures Type A Type B<br />

‡, * †, * †, * †, *<br />

‡, * †, * †, * †, *<br />

‡, * †, * †, * †, *<br />

‡ Project Manager to state location(s) with<br />

drawing references as appropriate.<br />

† Project Manager to either tick the relevant box<br />

or state any specific requirements (e.g.<br />

bitumen grade).<br />

* Advice for Project Manager given in<br />

Clauses Z.1, Z.6 <strong>and</strong> Z.7 <strong>of</strong> Appendix Z.<br />

4.2 DESIGN MIXTURES<br />

4.2.1 The composition <strong>of</strong> design mixtures shall<br />

comply with the requirements for either a Type A<br />

or a Type B mixture as directed by sub-<br />

Clause 4.1.3.<br />

4.2.2 Design <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong> mixtures shall<br />

be designed by the Contractor in his laboratory,<br />

using the aggregate size appropriate to the layer<br />

thickness as specified in Clause 3.8.<br />

4.2.3 At the target binder content for design<br />

mixtures, the Marshall stability determined in<br />

accordance with BS EN 12697-34 shall conform<br />

to the BS EN 13108-1 Category <strong>of</strong> *.<br />

* Project Manager to provide Category for<br />

specific job specification; advice given in<br />

Clause Z.7 <strong>of</strong> Appendix Z.<br />

(NOTE 1. Where 40 mm thick surface course or thinner<br />

is specified, a binder <strong>of</strong> greater penetration than 40/60<br />

grade bitumen is recommended provided the minimum<br />

stability requirement can be achieved. Extra workability<br />

will be gained <strong>and</strong> more time for compaction will be<br />

available.)<br />

(NOTE 2. If it is necessary to increase the binder<br />

content to more than the optimum binder content to<br />

achieve the target binder content with an air voids<br />

content <strong>of</strong> less than 4.0 %, the stability value at the<br />

target binder content shall meet the minimum<br />

requirement above.)<br />

(NOTE 3. The target binder content should be pitched<br />

such that, at the binder content <strong>of</strong> target + 0.4 %, the<br />

minimum stability value can be achieved <strong>and</strong>, at the<br />

target -0.4 % binder content, the air voids conforms to<br />

BS EN 13108-4 Category V max 4.)<br />

4.2.4 At the target binder content for design<br />

mixtures, the air voids content determined in<br />

accordance with BS EN 12697-5 shall conform to<br />

the BS EN 13108-4 Categories Vmax4 <strong>and</strong> Vmin2,0.<br />

(NOTE. A well compacted mat having a design air<br />

voids content <strong>of</strong> less than 4 % is expected to provide<br />

good durability.)<br />

July 2010 11