Hot Rolled Asphalt and Asphalt Concrete (Macadam) - Ministry of ...

Hot Rolled Asphalt and Asphalt Concrete (Macadam) - Ministry of ...

Hot Rolled Asphalt and Asphalt Concrete (Macadam) - Ministry of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

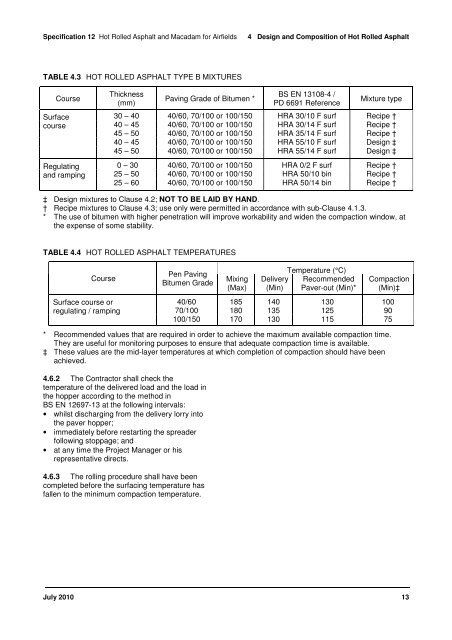

Specification 12 <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong> <strong>and</strong> <strong>Macadam</strong> for Airfields 4 Design <strong>and</strong> Composition <strong>of</strong> <strong>Hot</strong> <strong>Rolled</strong> <strong>Asphalt</strong><br />

TABLE 4.3 HOT ROLLED ASPHALT TYPE B MIXTURES<br />

Course<br />

Surface<br />

course<br />

Regulating<br />

<strong>and</strong> ramping<br />

Thickness<br />

(mm)<br />

Paving Grade <strong>of</strong> Bitumen *<br />

BS EN 13108-4 /<br />

PD 6691 Reference<br />

Mixture type<br />

30 – 40 40/60, 70/100 or 100/150 HRA 30/10 F surf Recipe †<br />

40 – 45 40/60, 70/100 or 100/150 HRA 30/14 F surf Recipe †<br />

45 – 50 40/60, 70/100 or 100/150 HRA 35/14 F surf Recipe †<br />

40 – 45 40/60, 70/100 or 100/150 HRA 55/10 F surf Design ‡<br />

45 – 50 40/60, 70/100 or 100/150 HRA 55/14 F surf Design ‡<br />

0 – 30 40/60, 70/100 or 100/150 HRA 0/2 F surf Recipe †<br />

25 – 50 40/60, 70/100 or 100/150 HRA 50/10 bin Recipe †<br />

25 – 60 40/60, 70/100 or 100/150 HRA 50/14 bin Recipe †<br />

‡ Design mixtures to Clause 4.2; NOT TO BE LAID BY HAND.<br />

† Recipe mixtures to Clause 4.3; use only were permitted in accordance with sub-Clause 4.1.3.<br />

* The use <strong>of</strong> bitumen with higher penetration will improve workability <strong>and</strong> widen the compaction window, at<br />

the expense <strong>of</strong> some stability.<br />

TABLE 4.4 HOT ROLLED ASPHALT TEMPERATURES<br />

Course<br />

Surface course or<br />

regulating / ramping<br />

Pen Paving<br />

Bitumen Grade<br />

Mixing<br />

(Max)<br />

Delivery<br />

(Min)<br />

Temperature (°C)<br />

Recommended<br />

Paver-out (Min)*<br />

Compaction<br />

(Min)‡<br />

40/60 185 140 130 100<br />

70/100 180 135 125 90<br />

100/150 170 130 115 75<br />

* Recommended values that are required in order to achieve the maximum available compaction time.<br />

They are useful for monitoring purposes to ensure that adequate compaction time is available.<br />

‡ These values are the mid-layer temperatures at which completion <strong>of</strong> compaction should have been<br />

achieved.<br />

4.6.2 The Contractor shall check the<br />

temperature <strong>of</strong> the delivered load <strong>and</strong> the load in<br />

the hopper according to the method in<br />

BS EN 12697-13 at the following intervals:<br />

• whilst discharging from the delivery lorry into<br />

the paver hopper;<br />

• immediately before restarting the spreader<br />

following stoppage; <strong>and</strong><br />

• at any time the Project Manager or his<br />

representative directs.<br />

4.6.3 The rolling procedure shall have been<br />

completed before the surfacing temperature has<br />

fallen to the minimum compaction temperature.<br />

July 2010 13