THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Seal and Gasket Design 113<br />

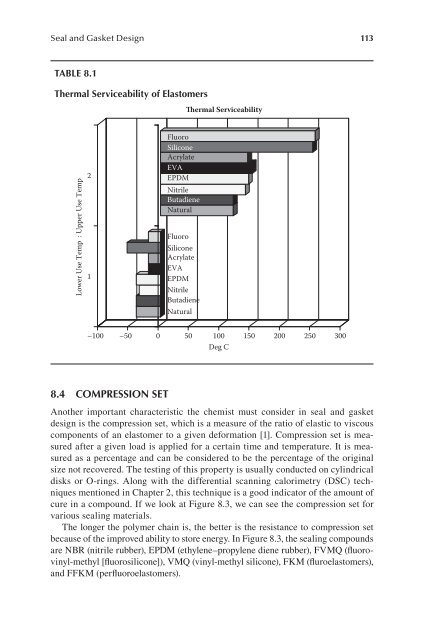

table 8.1<br />

thermal serviceability of elastomers<br />

Lower Use Temp : Upper Use Temp<br />

2<br />

1<br />

8.4 comPressIon set<br />

Fluoro<br />

Silicone<br />

Acrylate<br />

EVA<br />

EPDM<br />

Nitrile<br />

Butadiene<br />

Natural<br />

Fluoro<br />

Silicone<br />

Acrylate<br />

EVA<br />

EPDM<br />

Nitrile<br />

Butadiene<br />

Natural<br />

Thermal Serviceability<br />

–100 –50 0 50 100 150 200 250 300<br />

Deg C<br />

Another important characteristic the chemist must consider in seal and gasket<br />

design is the compression set, which is a measure of the ratio of elastic to viscous<br />

components of an elastomer to a given deformation [1]. Compression set is measured<br />

after a given load is applied for a certain time and temperature. It is measured<br />

as a percentage and can be considered to be the percentage of the original<br />

size not recovered. The testing of this property is usually conducted on cylindrical<br />

disks or O-rings. Along with the differential scanning calorimetry (DSC) techniques<br />

mentioned in Chapter 2, this technique is a good indicator of the amount of<br />

cure in a compound. If we look at Figure 8.3, we can see the compression set for<br />

various sealing materials.<br />

The longer the polymer chain is, the better is the resistance to compression set<br />

because of the improved ability to store energy. In Figure 8.3, the sealing compounds<br />

are NBR (nitrile rubber), EPDM (ethylene–propylene diene rubber), FVMQ (fluorovinyl-methyl<br />

[fluorosilicone]), VMQ (vinyl-methyl silicone), FKM (fluroelastomers),<br />

and FFKM (perfluoroelastomers).