THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Design Concerns and Imperatives 53<br />

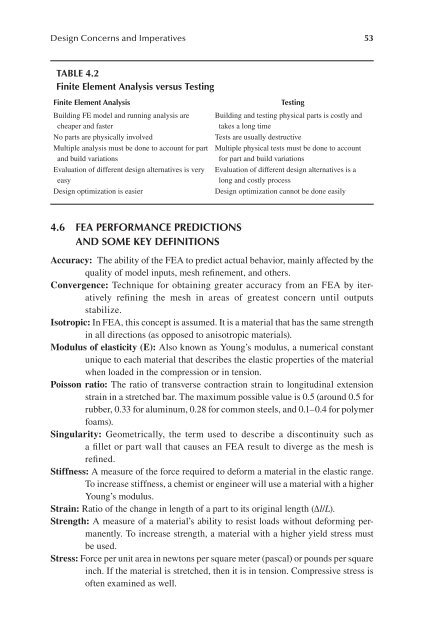

table 4.2<br />

Finite element analysis versus testing<br />

Finite element analysis testing<br />

Building FE model and running analysis are<br />

cheaper and faster<br />

4.6 Fea PerFormance PredIctIons<br />

and some Key deFInItIons<br />

Building and testing physical parts is costly and<br />

takes a long time<br />

No parts are physically involved Tests are usually destructive<br />

Multiple analysis must be done to account for part<br />

and build variations<br />

Evaluation of different design alternatives is very<br />

easy<br />

Multiple physical tests must be done to account<br />

for part and build variations<br />

Evaluation of different design alternatives is a<br />

long and costly process<br />

Design optimization is easier Design optimization cannot be done easily<br />

Accuracy: The ability of the FEA to predict actual behavior, mainly affected by the<br />

quality of model inputs, mesh refinement, and others.<br />

Convergence: Technique for obtaining greater accuracy from an FEA by iteratively<br />

refining the mesh in areas of greatest concern until outputs<br />

stabilize.<br />

Isotropic: In FEA, this concept is assumed. It is a material that has the same strength<br />

in all directions (as opposed to anisotropic materials).<br />

Modulus of elasticity (E): Also known as Young’s modulus, a numerical constant<br />

unique to each material that describes the elastic properties of the material<br />

when loaded in the compression or in tension.<br />

Poisson ratio: The ratio of transverse contraction strain to longitudinal extension<br />

strain in a stretched bar. The maximum possible value is 0.5 (around 0.5 for<br />

rubber, 0.33 for aluminum, 0.28 for common steels, and 0.1–0.4 for polymer<br />

foams).<br />

Singularity: Geometrically, the term used to describe a discontinuity such as<br />

a fillet or part wall that causes an FEA result to diverge as the mesh is<br />

refined.<br />

Stiffness: A measure of the force required to deform a material in the elastic range.<br />

To increase stiffness, a chemist or engineer will use a material with a higher<br />

Young’s modulus.<br />

Strain: Ratio of the change in length of a part to its original length (∆l/L).<br />

Strength: A measure of a material’s ability to resist loads without deforming permanently.<br />

To increase strength, a material with a higher yield stress must<br />

be used.<br />

Stress: Force per unit area in newtons per square meter (pascal) or pounds per square<br />

inch. If the material is stretched, then it is in tension. Compressive stress is<br />

often examined as well.