THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

72 The Role of the Chemist in Automotive Design<br />

piston or plunger will push the granules into the hopper when the barrel is withdrawn<br />

into a heated barrel. A screw within the barrel is rotated thereby feeding the pellets<br />

through the screw’s grooves. The barrel has heated zones that assist in the process;<br />

however, a great deal of heat and pressure is generated as the screw flights decrease<br />

toward the end of the screw toward the mold. This mechanical action will heat the<br />

plastic as the screw rotates.<br />

The sprue is the channel from which the resin will flow through the gate and<br />

into the mold. Runners are perpendicular to the direction of draw, and the sprue is<br />

parallel to the direction of draw. This portion of the system is often recycled because<br />

typical OEMs allow up to 15% of regrind material (the use of polymer salvaged from<br />

the runner or sprue and not used in the original part). When injection molding takes<br />

place, automotive thermoplastics must be cooled under the T m or T g before ejection.<br />

Injection mold machines are rated by their ability to mold polystyrene in a single<br />

shot [3]. Mold pressures can range from 55 to 275 MPa and cycles as low as 15 s. It is<br />

possible to injection mold a thermoset resin, although it is very difficult. Compression<br />

molding or transfer molding is used in these cases:<br />

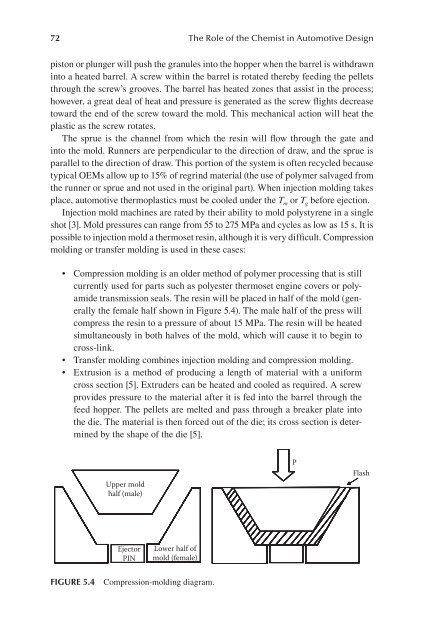

• Compression molding is an older method of polymer processing that is still<br />

currently used for parts such as polyester thermoset engine covers or polyamide<br />

transmission seals. The resin will be placed in half of the mold (generally<br />

the female half shown in Figure 5.4). The male half of the press will<br />

compress the resin to a pressure of about 15 MPa. The resin will be heated<br />

simultaneously in both halves of the mold, which will cause it to begin to<br />

cross-link.<br />

• Transfer molding combines injection molding and compression molding.<br />

• Extrusion is a method of producing a length of material with a uniform<br />

cross section [5]. Extruders can be heated and cooled as required. A screw<br />

provides pressure to the material after it is fed into the barrel through the<br />

feed hopper. The pellets are melted and pass through a breaker plate into<br />

the die. The material is then forced out of the die; its cross section is determined<br />

by the shape of the die [5].<br />

Upper mold<br />

half (male)<br />

Ejector<br />

PIN<br />

Lower half of<br />

mold (female)<br />

FIgure 5.4 Compression-molding diagram.<br />

P<br />

Flash