THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Developing Technology 179<br />

Positive<br />

LiCoO 2<br />

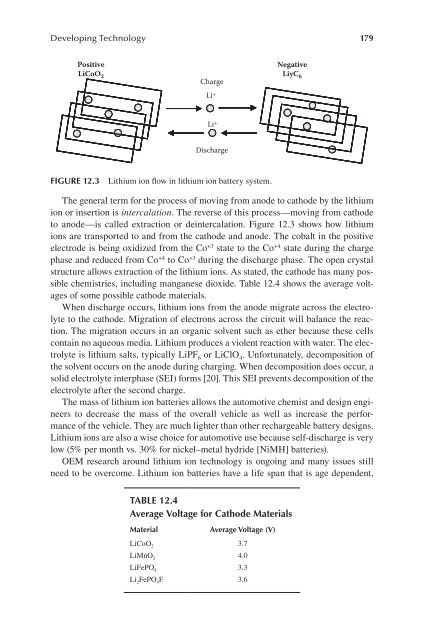

The general term for the process of moving from anode to cathode by the lithium<br />

ion or insertion is intercalation. The reverse of this process—moving from cathode<br />

to anode—is called extraction or deintercalation. Figure 12.3 shows how lithium<br />

ions are transported to and from the cathode and anode. The cobalt in the positive<br />

electrode is being oxidized from the Co +3 state to the Co +4 state during the charge<br />

phase and reduced from Co +4 to Co +3 during the discharge phase. The open crystal<br />

structure allows extraction of the lithium ions. As stated, the cathode has many possible<br />

chemistries, including manganese dioxide. Table 12.4 shows the average voltages<br />

of some possible cathode materials.<br />

When discharge occurs, lithium ions from the anode migrate across the electrolyte<br />

to the cathode. Migration of electrons across the circuit will balance the reaction.<br />

The migration occurs in an organic solvent such as ether because these cells<br />

contain no aqueous media. Lithium produces a violent reaction with water. The electrolyte<br />

is lithium salts, typically LiPF 6 or LiClO 4. Unfortunately, decomposition of<br />

the solvent occurs on the anode during charging. When decomposition does occur, a<br />

solid electrolyte interphase (SEI) forms [20]. This SEI prevents decomposition of the<br />

electrolyte after the second charge.<br />

The mass of lithium ion batteries allows the automotive chemist and design engineers<br />

to decrease the mass of the overall vehicle as well as increase the performance<br />

of the vehicle. They are much lighter than other rechargeable battery designs.<br />

Lithium ions are also a wise choice for automotive use because self-discharge is very<br />

low (5% per month vs. 30% for nickel–metal hydride [NiMH] batteries).<br />

OEM research around lithium ion technology is ongoing and many issues still<br />

need to be overcome. Lithium ion batteries have a life span that is age dependent,<br />

table 12.4<br />

average voltage for cathode materials<br />

material average voltage (v)<br />

LiCoO 2<br />

LiMnO 2<br />

LiFePO 4<br />

Charge<br />

Li +<br />

Li +<br />

Discharge<br />

FIgure 12.3 Lithium ion flow in lithium ion battery system.<br />

3.7<br />

4.0<br />

3.3<br />

Li 2FePO 4F 3.6<br />

Negative<br />

LiyC 6