THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

126 The Role of the Chemist in Automotive Design<br />

the Poisson ratio is slightly less than 0.5, then the material is nearly incompressible<br />

[14]. Viscoelasticity is rate-dependent behavior with properties that change with temperature<br />

and time. The features of a viscoelastic material are as follows [14]:<br />

•<br />

•<br />

•<br />

•<br />

creep under constant stress;<br />

relaxation under constant strain;<br />

hysteresis under loading and unloading cycles;<br />

internal friction rearrangement of molecular structures under load;<br />

• strain-induced crystallization formation and<br />

melting of crystallized regions;.<br />

• stress softening; and<br />

• breakdown of the reinforcing filler and polymer<br />

bonds.<br />

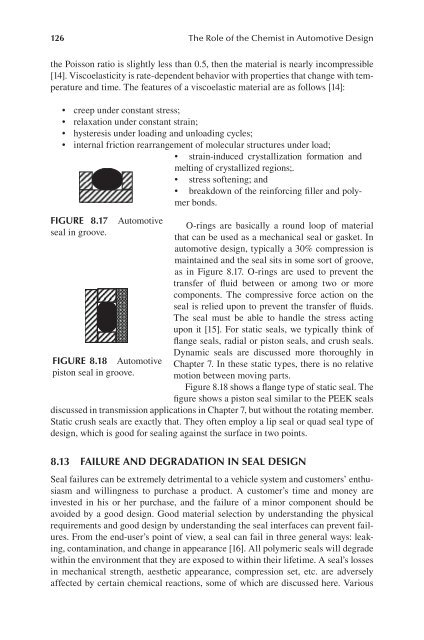

FIgure 8.17 Automotive<br />

seal in groove.<br />

FIgure 8.18 Automotive<br />

piston seal in groove.<br />

O-rings are basically a round loop of material<br />

that can be used as a mechanical seal or gasket. In<br />

automotive design, typically a 30% compression is<br />

maintained and the seal sits in some sort of groove,<br />

as in Figure 8.17. O-rings are used to prevent the<br />

transfer of fluid between or among two or more<br />

components. The compressive force action on the<br />

seal is relied upon to prevent the transfer of fluids.<br />

The seal must be able to handle the stress acting<br />

upon it [15]. For static seals, we typically think of<br />

flange seals, radial or piston seals, and crush seals.<br />

Dynamic seals are discussed more thoroughly in<br />

Chapter 7. In these static types, there is no relative<br />

motion between moving parts.<br />

Figure 8.18 shows a flange type of static seal. The<br />

figure shows a piston seal similar to the PEEK seals<br />

discussed in transmission applications in Chapter 7, but without the rotating member.<br />

Static crush seals are exactly that. They often employ a lip seal or quad seal type of<br />

design, which is good for sealing against the surface in two points.<br />

8.13 FaIlure and degradatIon In seal desIgn<br />

Seal failures can be extremely detrimental to a vehicle system and customers’ enthusiasm<br />

and willingness to purchase a product. A customer’s time and money are<br />

invested in his or her purchase, and the failure of a minor component should be<br />

avoided by a good design. Good material selection by understanding the physical<br />

requirements and good design by understanding the seal interfaces can prevent failures.<br />

From the end-user’s point of view, a seal can fail in three general ways: leaking,<br />

contamination, and change in appearance [16]. All polymeric seals will degrade<br />

within the environment that they are exposed to within their lifetime. A seal’s losses<br />

in mechanical strength, aesthetic appearance, compression set, etc. are adversely<br />

affected by certain chemical reactions, some of which are discussed here. Various