THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

42 The Role of the Chemist in Automotive Design<br />

dominant step and therefore the only effective step that consumes the monomer. The<br />

rate of polymerization (R p) is<br />

R<br />

dM ⎡ ⎤<br />

=− ⎣⎢ ⎦⎥<br />

= k ⎡M•⎤M<br />

dt ⎣⎢ ⎦⎥ ⎡ ⎤<br />

⎣⎢ ⎦⎥<br />

p p<br />

3.8 steP growtH PolymerIzatIon<br />

(3.5)<br />

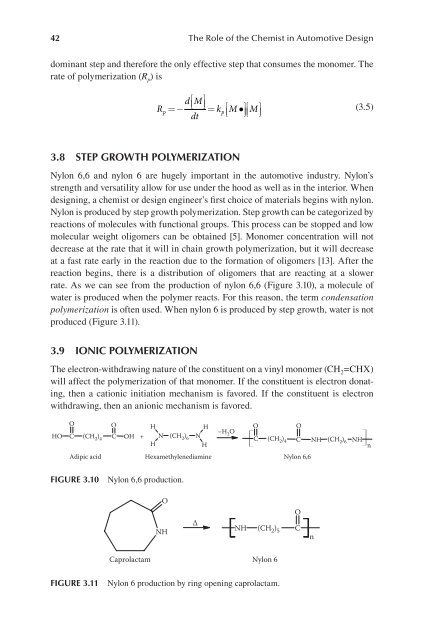

Nylon 6,6 and nylon 6 are hugely important in the automotive industry. Nylon’s<br />

strength and versatility allow for use under the hood as well as in the interior. When<br />

designing, a chemist or design engineer’s first choice of materials begins with nylon.<br />

Nylon is produced by step growth polymerization. Step growth can be categorized by<br />

reactions of molecules with functional groups. This process can be stopped and low<br />

molecular weight oligomers can be obtained [5]. Monomer concentration will not<br />

decrease at the rate that it will in chain growth polymerization, but it will decrease<br />

at a fast rate early in the reaction due to the formation of oligomers [13]. After the<br />

reaction begins, there is a distribution of oligomers that are reacting at a slower<br />

rate. As we can see from the production of nylon 6,6 (Figure 3.10), a molecule of<br />

water is produced when the polymer reacts. For this reason, the term condensation<br />

polymerization is often used. When nylon 6 is produced by step growth, water is not<br />

produced (Figure 3.11).<br />

3.9 IonIc PolymerIzatIon<br />

The electron-withdrawing nature of the constituent on a vinyl monomer (CH 2=CHX)<br />

will affect the polymerization of that monomer. If the constituent is electron donating,<br />

then a cationic initiation mechanism is favored. If the constituent is electron<br />

withdrawing, then an anionic mechanism is favored.<br />

O<br />

O<br />

HO C (CH2 ) 4 C OH +<br />

H<br />

N<br />

H<br />

(CH 2 ) 6<br />

H<br />

N<br />

H<br />

–H 2 O<br />

(CH 2 ) 4<br />

Adipic acid Hexamethylenediamine Nylon 6,6<br />

FIgure 3.10 Nylon 6,6 production.<br />

O<br />

NH<br />

∆<br />

NH<br />

O<br />

C<br />

(CH 2 ) 5<br />

Caprolactam Nylon 6<br />

FIgure 3.11 Nylon 6 production by ring opening caprolactam.<br />

O<br />

C<br />

O<br />

C<br />

NH<br />

n<br />

(CH 2 ) 6<br />

NH<br />

n