THE ROLE OF THE

THE ROLE OF THE

THE ROLE OF THE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Seal and Gasket Design 119<br />

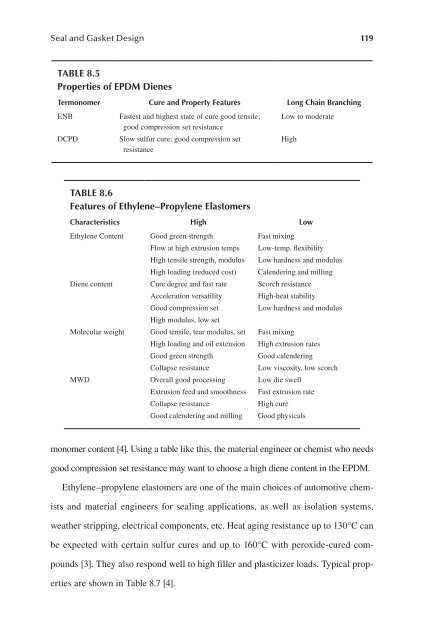

table 8.5<br />

Properties of ePdm dienes<br />

termonomer cure and Property Features long chain branching<br />

ENB Fastest and highest state of cure good tensile;<br />

good compression set resistance<br />

DCPD Slow sulfur cure; good compression set<br />

resistance<br />

table 8.6<br />

Features of ethylene–Propylene elastomers<br />

monomer content [4]. Using a table like this, the material engineer or chemist who needs<br />

good compression set resistance may want to choose a high diene content in the EPDM.<br />

Ethylene–propylene elastomers are one of the main choices of automotive chem-<br />

ists and material engineers for sealing applications, as well as isolation systems,<br />

weather stripping, electrical components, etc. Heat aging resistance up to 130°C can<br />

be expected with certain sulfur cures and up to 160°C with peroxide-cured com-<br />

pounds [3]. They also respond well to high filler and plasticizer loads. Typical prop-<br />

erties are shown in Table 8.7 [4].<br />

Low to moderate<br />

High<br />

characteristics High low<br />

Ethylene Content Good green strength Fast mixing<br />

Flow at high extrusion temps Low-temp. flexibility<br />

High tensile strength, modulus Low hardness and modulus<br />

High loading (reduced cost) Calendering and milling<br />

Diene content Cure degree and fast rate Scorch resistance<br />

Acceleration versatility High-heat stability<br />

Good compression set<br />

High modulus, low set<br />

Low hardness and modulus<br />

Molecular weight Good tensile, tear modulus, set Fast mixing<br />

High loading and oil extension High extrusion rates<br />

Good green strength Good calendering<br />

Collapse resistance Low viscosity, low scorch<br />

MWD Overall good processing Low die swell<br />

Extrusion feed and smoothness Fast extrusion rate<br />

Collapse resistance High cure<br />

Good calendering and milling Good physicals