appendix 1 - Victor Technologies

appendix 1 - Victor Technologies

appendix 1 - Victor Technologies

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Logic PC Board controls the timing and sequencing of<br />

the system. It monitors the pressure, temperature, and<br />

flow interlocks and controls the gas flow in run and set<br />

modes by turning on the plasma and secondary solenoids.<br />

The Logic PC Board also controls the power on the voltage<br />

selection and prepurge functions.<br />

After the ON/OFF switch is closed on the front panel, the<br />

AC Indicator blinks and the GAS Indicator is on steady.<br />

The AC Indicator blinks for approximately 8 seconds then<br />

at that time it becomes steady and the inrush relay closes.<br />

The GAS Indicator stays on for approximately 20 seconds<br />

(prepurge function) then goes off and the gas stops flowing.<br />

When the torch switch is pressed, D26 "start" Indicator<br />

comes on, gas will flow for approximately 2 seconds before<br />

DC is established (indicated on the front panel). During<br />

this time D25 CD Enable will come on and sends a logic<br />

signal to the CD Board which fires the spark gap and initiates<br />

the torch to pilot. D25 should go out immediately if<br />

the pilot starts immediately.<br />

When the torch is close to the workpiece, the cutting arc<br />

"transfers" to the work. Also, if the tip touches the workpiece,<br />

the current is automatically folded back to approximately<br />

35 amps to save the tip from being blown out.<br />

The resulting current is sensed by the Current Sense PC<br />

Board, resulting in the demand level changing from pilot<br />

current to whatever the main current control is set at. During<br />

the "transfer" the CSR Indicator (D65) comes on and<br />

the transfer enable signal goes low allowing the bottom<br />

gate drive and FET modules to come up and start running.<br />

Also at this time, D5 (located on the Pilot Output PC Board)<br />

shuts off and at this time the main cutting arc is initiated. If<br />

the torch is removed from the workpiece, the pilot arc will<br />

automatically restart if the torch switch is still pressed.<br />

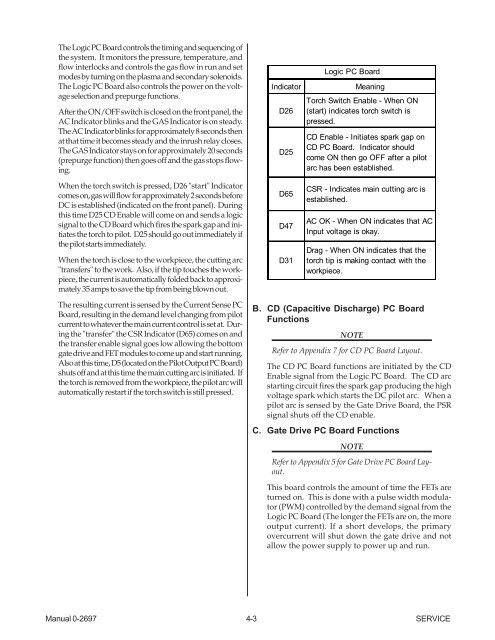

Indicator Meaning<br />

Manual 0-2697 4-3 SERVICE<br />

D26<br />

D25<br />

D65<br />

D47<br />

D31<br />

Logic PC Board<br />

Torch Switch Enable - When ON<br />

(start) indicates torch switch is<br />

pressed.<br />

CD Enable - Initiates spark gap on<br />

CD PC Board. Indicator should<br />

come ON then go OFF after a pilot<br />

arc has been established.<br />

CSR - Indicates main cutting arc is<br />

established.<br />

AC OK - When ON indicates that AC<br />

Input voltage is okay.<br />

Drag - When ON indicates that the<br />

torch tip is making contact with the<br />

workpiece.<br />

B. CD (Capacitive Discharge) PC Board<br />

Functions<br />

NOTE<br />

Refer to Appendix 7 for CD PC Board Layout.<br />

The CD PC Board functions are initiated by the CD<br />

Enable signal from the Logic PC Board. The CD arc<br />

starting circuit fires the spark gap producing the high<br />

voltage spark which starts the DC pilot arc. When a<br />

pilot arc is sensed by the Gate Drive Board, the PSR<br />

signal shuts off the CD enable.<br />

C. Gate Drive PC Board Functions<br />

NOTE<br />

Refer to Appendix 5 for Gate Drive PC Board Layout.<br />

This board controls the amount of time the FETs are<br />

turned on. This is done with a pulse width modulator<br />

(PWM) controlled by the demand signal from the<br />

Logic PC Board (The longer the FETs are on, the more<br />

output current). If a short develops, the primary<br />

overcurrent will shut down the gate drive and not<br />

allow the power supply to power up and run.