HN 2: The British and their Works

HN 2: The British and their Works

HN 2: The British and their Works

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

the adherence to manufacturing tolerances. <strong>The</strong> second phase<br />

called for the elimination of defects, <strong>and</strong> improvements in the<br />

vehicle <strong>and</strong> its equipment, without undertaking any design<br />

modifications. In phase three, postponed by the Board of Control<br />

for the time being, the design of a new vehicle was to be put in<br />

train. 173<br />

At the end of 1947, general manager Münch was able to present<br />

a positive balance sheet. <strong>The</strong> carburettors developed by Solex<br />

had been modified in such a way that a faultless idling <strong>and</strong> transition<br />

to acceleration were achieved. With the development of a<br />

new felt-element air filter <strong>and</strong> a deflector inserted in the<br />

cooling-air intake, the serious fouling <strong>and</strong> over-cooling of the<br />

engine were prevented. This had a positive effect on the service<br />

life of the cylinders, whose quality had been improved by an<br />

alteration to the composition of the alloy used <strong>and</strong> to the milling<br />

process. When the cylinders <strong>and</strong> pistons were lengthened,<br />

the Volkswagen ran more quietly. <strong>The</strong> crankshaft production line<br />

was modified in order to achieve better adherence to tolerances<br />

in manufacture. <strong>The</strong> loosening of the camshaft wheel was<br />

eliminated by improved riveting. Frequently occurring running<br />

noises from the disc wheel <strong>and</strong> bevel gear disappeared thanks<br />

to a new device permitting precise adjustment. In the gearbox<br />

the dimensional precision <strong>and</strong> surface quality of the gears,<br />

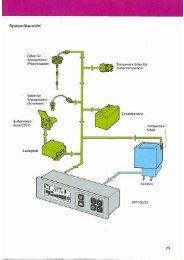

running parts <strong>and</strong> bearings were improved. A new noise monitoring<br />

device was set up to examine the running noise in the<br />

differential <strong>and</strong> the gearbox. <strong>The</strong> rattling of the front axle had<br />

disappeared; the steering worked well. <strong>The</strong> necessary corrections<br />

had been implemented in the fitting of panels, with the<br />

result that doors <strong>and</strong> lids now closed properly. 174<br />

One important innovation was still at the design stage. At the<br />

beginning of September 1947 Josef Kales began installing a<br />

hydraulic brake produced by the Teves company, which gave rise<br />

to considerable design problems in the re-siting of the h<strong>and</strong>brake.<br />

175 It seems that these problems were insoluble, as the<br />

Volkswagen had cable brakes up until the fifties. Nonetheless,<br />

since start of production the saloon had undergone a sort of<br />

metamorphosis, which Hirst in retrospect demonstrated, taking<br />

the steering as an example: "We started with a car whose<br />

steering was wobbly. I said, okay, get the wheels balanced, <strong>and</strong><br />

they did. Change the steering box, so they did. Change the front<br />

axle, so they did. And we had a different car." 176 ■<br />

70 71<br />

STRIVING FOR QUALITY