HN 2: The British and their Works

HN 2: The British and their Works

HN 2: The British and their Works

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

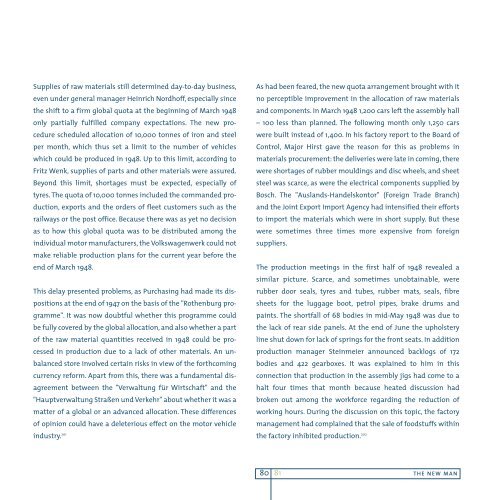

Supplies of raw materials still determined day-to-day business,<br />

even under general manager Heinrich Nordhoff, especially since<br />

the shift to a firm global quota at the beginning of March 1948<br />

only partially fulfilled company expectations. <strong>The</strong> new procedure<br />

scheduled allocation of 10,000 tonnes of iron <strong>and</strong> steel<br />

per month, which thus set a limit to the number of vehicles<br />

which could be produced in 1948. Up to this limit, according to<br />

Fritz Wenk, supplies of parts <strong>and</strong> other materials were assured.<br />

Beyond this limit, shortages must be expected, especially of<br />

tyres. <strong>The</strong> quota of 10,000 tonnes included the comm<strong>and</strong>ed production,<br />

exports <strong>and</strong> the orders of fleet customers such as the<br />

railways or the post office. Because there was as yet no decision<br />

as to how this global quota was to be distributed among the<br />

individual motor manufacturers, the Volkswagenwerk could not<br />

make reliable production plans for the current year before the<br />

end of March 1948.<br />

This delay presented problems, as Purchasing had made its dispositions<br />

at the end of 1947 on the basis of the "Rothenburg programme".<br />

It was now doubtful whether this programme could<br />

be fully covered by the global allocation, <strong>and</strong> also whether a part<br />

of the raw material quantities received in 1948 could be processed<br />

in production due to a lack of other materials. An unbalanced<br />

store involved certain risks in view of the forthcoming<br />

currency reform. Apart from this, there was a fundamental disagreement<br />

between the "Verwaltung für Wirtschaft" <strong>and</strong> the<br />

"Hauptverwaltung Straßen und Verkehr" about whether it was a<br />

matter of a global or an advanced allocation. <strong>The</strong>se differences<br />

of opinion could have a deleterious effect on the motor vehicle<br />

industry. 201<br />

As had been feared, the new quota arrangement brought with it<br />

no perceptible improvement in the allocation of raw materials<br />

<strong>and</strong> components. In March 1948 1,200 cars left the assembly hall<br />

– 100 less than planned. <strong>The</strong> following month only 1,250 cars<br />

were built instead of 1,400. In his factory report to the Board of<br />

Control, Major Hirst gave the reason for this as problems in<br />

materials procurement: the deliveries were late in coming, there<br />

were shortages of rubber mouldings <strong>and</strong> disc wheels, <strong>and</strong> sheet<br />

steel was scarce, as were the electrical components supplied by<br />

Bosch. <strong>The</strong> "Ausl<strong>and</strong>s-H<strong>and</strong>elskontor" (Foreign Trade Branch)<br />

<strong>and</strong> the Joint Export Import Agency had intensified <strong>their</strong> efforts<br />

to import the materials which were in short supply. But these<br />

were sometimes three times more expensive from foreign<br />

suppliers.<br />

<strong>The</strong> production meetings in the first half of 1948 revealed a<br />

similar picture. Scarce, <strong>and</strong> sometimes unobtainable, were<br />

rubber door seals, tyres <strong>and</strong> tubes, rubber mats, seals, fibre<br />

sheets for the luggage boot, petrol pipes, brake drums <strong>and</strong><br />

paints. <strong>The</strong> shortfall of 68 bodies in mid-May 1948 was due to<br />

the lack of rear side panels. At the end of June the upholstery<br />

line shut down for lack of springs for the front seats. In addition<br />

production manager Steinmeier announced backlogs of 172<br />

bodies <strong>and</strong> 422 gearboxes. It was explained to him in this<br />

connection that production in the assembly jigs had come to a<br />

halt four times that month because heated discussion had<br />

broken out among the workforce regarding the reduction of<br />

working hours. During the discussion on this topic, the factory<br />

management had complained that the sale of foodstuffs within<br />

the factory inhibited production. 202<br />

80 81<br />

THE NEW MAN