KAMDHENU ISPAT LIMITED - Securities and Exchange Board of India

KAMDHENU ISPAT LIMITED - Securities and Exchange Board of India

KAMDHENU ISPAT LIMITED - Securities and Exchange Board of India

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

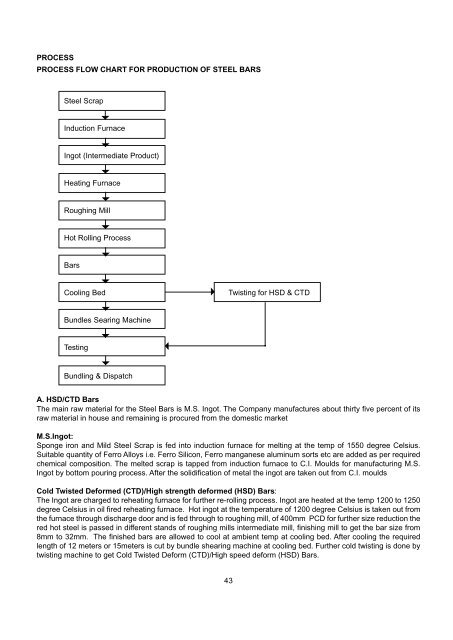

PROCESS<br />

PROCESS FLOW CHART FOR PRODUCTION OF STEEL BARS<br />

Steel Scrap<br />

Induction Furnace<br />

Ingot (Intermediate Product)<br />

Heating Furnace<br />

Roughing Mill<br />

Hot Rolling Process<br />

Bars<br />

Cooling Bed Twisting for HSD & CTD<br />

Bundles Searing Machine<br />

Testing<br />

Bundling & Dispatch<br />

A. HSD/CTD Bars<br />

The main raw material for the Steel Bars is M.S. Ingot. The Company manufactures about thirty five percent <strong>of</strong> its<br />

raw material in house <strong>and</strong> remaining is procured from the domestic market<br />

M.S.Ingot:<br />

Sponge iron <strong>and</strong> Mild Steel Scrap is fed into induction furnace for melting at the temp <strong>of</strong> 1550 degree Celsius.<br />

Suitable quantity <strong>of</strong> Ferro Alloys i.e. Ferro Silicon, Ferro manganese aluminum sorts etc are added as per required<br />

chemical composition. The melted scrap is tapped from induction furnace to C.I. Moulds for manufacturing M.S.<br />

Ingot by bottom pouring process. After the solidification <strong>of</strong> metal the ingot are taken out from C.I. moulds<br />

Cold Twisted Deformed (CTD)/High strength deformed (HSD) Bars:<br />

The Ingot are charged to reheating furnace for further re-rolling process. Ingot are heated at the temp 1200 to 1250<br />

degree Celsius in oil fired reheating furnace. Hot ingot at the temperature <strong>of</strong> 1200 degree Celsius is taken out from<br />

the furnace through discharge door <strong>and</strong> is fed through to roughing mill, <strong>of</strong> 400mm PCD for further size reduction the<br />

red hot steel is passed in different st<strong>and</strong>s <strong>of</strong> roughing mills intermediate mill, finishing mill to get the bar size from<br />

8mm to 32mm. The finished bars are allowed to cool at ambient temp at cooling bed. After cooling the required<br />

length <strong>of</strong> 12 meters or 15meters is cut by bundle shearing machine at cooling bed. Further cold twisting is done by<br />

twisting machine to get Cold Twisted Deform (CTD)/High speed deform (HSD) Bars.<br />

43