KAMDHENU ISPAT LIMITED - Securities and Exchange Board of India

KAMDHENU ISPAT LIMITED - Securities and Exchange Board of India

KAMDHENU ISPAT LIMITED - Securities and Exchange Board of India

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POWER<br />

The Company sources Power from Rajasthan State Electricity <strong>Board</strong> through dedicated high voltage feeder lines<br />

<strong>and</strong> do not have alternate source <strong>of</strong> electricity for our manufacturing facilities. The Company has an sanctioned<br />

capacity <strong>of</strong> 4990 KVA . This is enough to meet our requirement <strong>of</strong> electricity We are solely dependent on Jaipur<br />

Vidyut Vitran Nigam Limited for electric supply.<br />

PRODUCTS<br />

The Company derive income from three different activities.<br />

(a) Sale <strong>of</strong> Products manufactured by the Company.<br />

(b) Trading <strong>of</strong> products manufactured by Franchisees under “Kamadhenu” br<strong>and</strong>.<br />

(c) By way <strong>of</strong> royalities received from Franchisees for using “Kamadhenu” br<strong>and</strong>.<br />

Kamdhenu manufactures undermentioned quality <strong>of</strong> steel bars. Products <strong>of</strong> the company meet IS 1786-1985 <strong>and</strong><br />

ISO 9001:2000 specifications:<br />

CTD/HSD Bars:<br />

Cold Twisted Deformed Bars have high strength <strong>and</strong> pro<strong>of</strong> stress <strong>and</strong> are being produced by High Speed Rolling<br />

<strong>and</strong> precision cold twisting. The salient features <strong>of</strong> these products are:<br />

· Higher fatigue strength<br />

· 100% weldability<br />

· Satisfactory bendability<br />

· Suitable for both compression <strong>and</strong> tension reinforcement<br />

· Minimum weight <strong>and</strong> maximum strength<br />

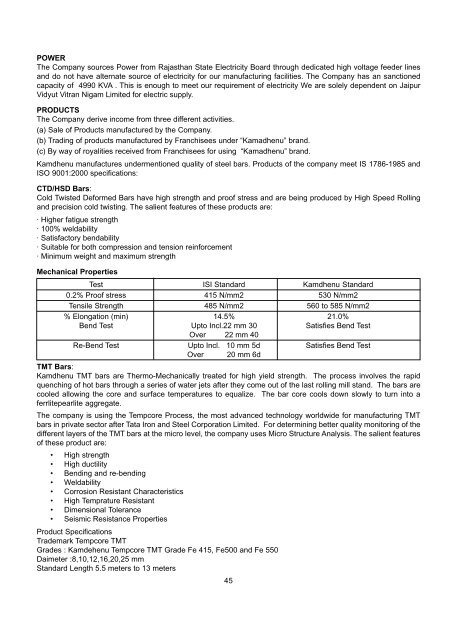

Mechanical Properties<br />

Test ISI St<strong>and</strong>ard Kamdhenu St<strong>and</strong>ard<br />

0.2% Pro<strong>of</strong> stress 415 N/mm2 530 N/mm2<br />

Tensile Strength 485 N/mm2 560 to 585 N/mm2<br />

% Elongation (min) 14.5% 21.0%<br />

Bend Test Upto Incl.22 mm 30 Satisfies Bend Test<br />

Over 22 mm 40<br />

Re-Bend Test Upto Incl. 10 mm 5d Satisfies Bend Test<br />

Over 20 mm 6d<br />

TMT Bars:<br />

Kamdhenu TMT bars are Thermo-Mechanically treated for high yield strength. The process involves the rapid<br />

quenching <strong>of</strong> hot bars through a series <strong>of</strong> water jets after they come out <strong>of</strong> the last rolling mill st<strong>and</strong>. The bars are<br />

cooled allowing the core <strong>and</strong> surface temperatures to equalize. The bar core cools down slowly to turn into a<br />

ferrlitepearlite aggregate.<br />

The company is using the Tempcore Process, the most advanced technology worldwide for manufacturing TMT<br />

bars in private sector after Tata Iron <strong>and</strong> Steel Corporation Limited. For determining better quality monitoring <strong>of</strong> the<br />

different layers <strong>of</strong> the TMT bars at the micro level, the company uses Micro Structure Analysis. The salient features<br />

<strong>of</strong> these product are:<br />

High strength<br />

High ductility<br />

Bending <strong>and</strong> re-bending<br />

Weldability<br />

Corrosion Resistant Characteristics<br />

High Temprature Resistant<br />

Dimensional Tolerance<br />

Seismic Resistance Properties<br />

Product Specifications<br />

Trademark Tempcore TMT<br />

Grades : Kamdehenu Tempcore TMT Grade Fe 415, Fe500 <strong>and</strong> Fe 550<br />

Daimeter :8,10,12,16,20,25 mm<br />

St<strong>and</strong>ard Length 5.5 meters to 13 meters<br />

45