Hi-Res PDF - CRCnetBASE

Hi-Res PDF - CRCnetBASE

Hi-Res PDF - CRCnetBASE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

254<br />

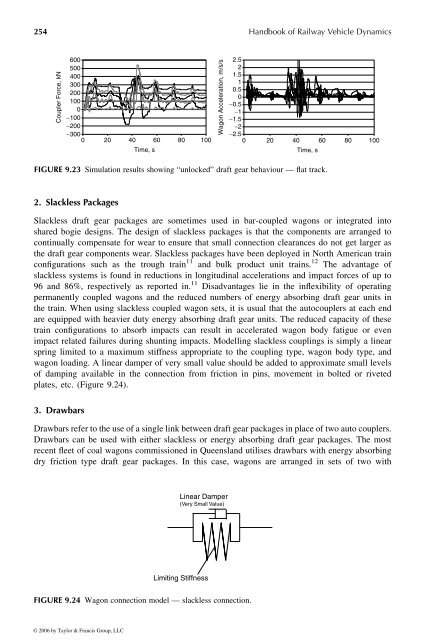

Coupler Force, kN<br />

2. Slackless Packages<br />

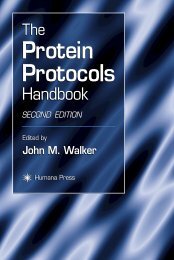

Slackless draft gear packages are sometimes used in bar-coupled wagons or integrated into<br />

shared bogie designs. The design of slackless packages is that the components are arranged to<br />

continually compensate for wear toensure that small connection clearances do not get larger as<br />

the draft gear components wear. Slackless packages have been deployed in North American train<br />

configurations such as the trough train 11 and bulk product unit trains. 12 The advantage of<br />

slackless systems is found in reductions in longitudinal accelerations and impact forces of up to<br />

96 and 86%, respectively as reported in. 11 Disadvantages lie in the inflexibility ofoperating<br />

permanently coupled wagons and the reduced numbers of energy absorbing draft gear units in<br />

the train. When using slackless coupled wagon sets, it is usual that the autocouplers at each end<br />

are equipped with heavier duty energy absorbing draft gear units. The reduced capacity of these<br />

train configurations to absorb impacts can result in accelerated wagon body fatigue or even<br />

impact related failures during shunting impacts. Modelling slackless couplings is simply alinear<br />

spring limited to amaximum stiffness appropriate to the coupling type, wagon body type, and<br />

wagon loading. Alinear damper of very small value should beadded to approximate small levels<br />

of damping available in the connection from friction in pins, movement in bolted or riveted<br />

plates, etc. (Figure 9.24).<br />

3. Drawbars<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

- 100<br />

- 200<br />

- 300<br />

0 20 40 60 80 100<br />

Time, s<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

- 0.5<br />

- 1<br />

- 1.5<br />

- 2<br />

- 2.5<br />

0 20 40 60 80 100<br />

Time, s<br />

FIGURE 9.23 Simulation results showing “unlocked” draft gear behaviour —flat track.<br />

Drawbars refer to the use of asingle link between draftgear packages in place of two auto couplers.<br />

Drawbars can be used with either slackless or energy absorbing draft gear packages. The most<br />

recent fleet of coal wagons commissioned in Queensland utilises drawbars with energy absorbing<br />

dry friction type draft gear packages. In this case, wagons are arranged in sets of two with<br />

Limiting Stiffness<br />

Wagon Acceleration, m/s/s<br />

Linear Damper<br />

(Very Small Value)<br />

FIGURE 9.24 Wagon connection model —slackless connection.<br />

© 2006 by Taylor & Francis Group, LLC<br />

Handbook of Railway Vehicle Dynamics