Hi-Res PDF - CRCnetBASE

Hi-Res PDF - CRCnetBASE

Hi-Res PDF - CRCnetBASE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

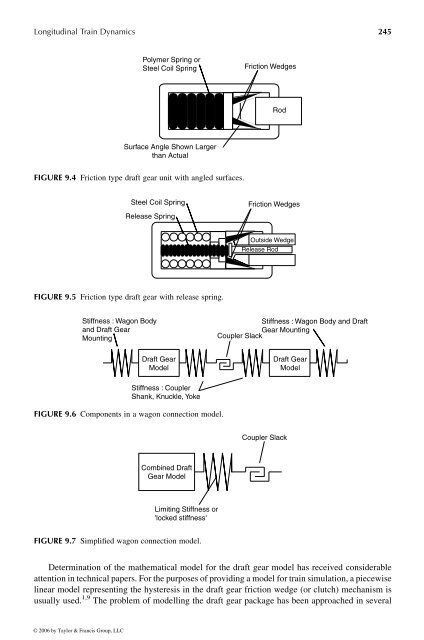

Longitudinal Train Dynamics 245<br />

Polymer Spring or<br />

Steel Coil Spring<br />

Surface Angle Shown Larger<br />

than Actual<br />

FIGURE 9.4 Friction type draft gear unit with angled surfaces.<br />

Friction Wedges<br />

Determination of the mathematical model for the draft gear model has received considerable<br />

attention in technical papers. For the purposes of providing amodel for train simulation, apiecewise<br />

linear model representing the hysteresis in the draft gear friction wedge (or clutch) mechanism is<br />

usually used. 1,9 The problem of modelling the draft gear package has been approached in several<br />

Rod<br />

Steel Coil Spring Friction Wedges<br />

Release Spring<br />

FIGURE 9.5 Friction type draft gear with release spring.<br />

Stiffness :Wagon Body<br />

and Draft Gear<br />

Mounting<br />

Draft Gear<br />

Model<br />

Stiffness :Coupler<br />

Shank, Knuckle,Yoke<br />

FIGURE 9.6 Components in awagon connection model.<br />

Combined Draft<br />

Gear Model<br />

Limiting Stiffness or<br />

'locked stiffness'<br />

FIGURE 9.7 Simplified wagon connection model.<br />

© 2006 by Taylor & Francis Group, LLC<br />

Outside Wedge<br />

Release Rod<br />

Stiffness :Wagon Body and Draft<br />

Gear Mounting<br />

Coupler Slack<br />

Coupler Slack<br />

Draft Gear<br />

Model