Kop-Flex Industrial Coupling Product Catalog - Form 8887E

Kop-Flex Industrial Coupling Product Catalog - Form 8887E

Kop-Flex Industrial Coupling Product Catalog - Form 8887E

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

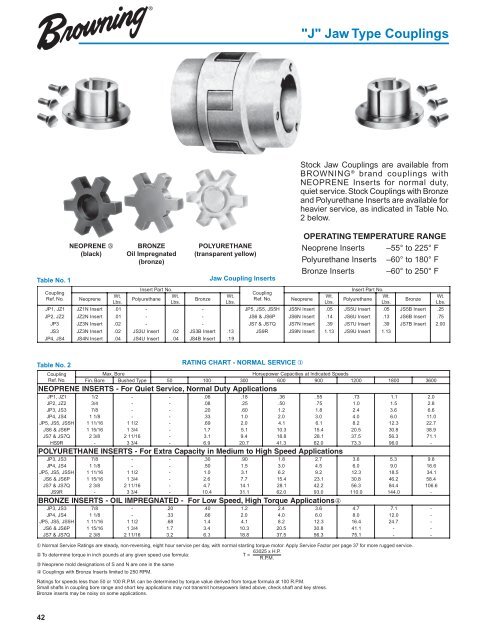

"J" Jaw Type <strong>Coupling</strong>s<br />

Stock Jaw <strong>Coupling</strong>s are available from<br />

BROWNING ® brand couplings with<br />

NEOPRENE Inserts for normal duty,<br />

quiet service. Stock <strong>Coupling</strong>s with Bronze<br />

and Polyurethane Inserts are available for<br />

heavier service, as indicated in Table No.<br />

2 below.<br />

Table No. 1<br />

<strong>Coupling</strong><br />

Ref. No.<br />

JP1,<br />

JZ1<br />

JP2,<br />

JZ2<br />

JP3<br />

JS3<br />

JP4,<br />

JS4<br />

NEOPRENE <br />

(black)<br />

Neoprene<br />

BRONZE<br />

Oil Impregnated<br />

(bronze)<br />

Insert Part<br />

Wt.<br />

Polyurethane<br />

Lbs.<br />

0<br />

0<br />

0<br />

. 0 S3U Insert<br />

. 0 S4U Insert<br />

No.<br />

Wt.<br />

Lbs.<br />

POLYURETHANE<br />

(transparent yellow)<br />

Bronze<br />

Jaw <strong>Coupling</strong> Inserts<br />

Wt.<br />

Lbs.<br />

<strong>Coupling</strong><br />

Ref. No.<br />

JZ1N Insert<br />

. 1 - - JP5,<br />

JS5, JS5H<br />

JZ2N Insert<br />

. 1 - - JS6<br />

& JS6P<br />

JZ3N Insert<br />

. 2<br />

- - JS7<br />

& JS7Q<br />

JZ3N Insert<br />

2 J . 02<br />

JS3B<br />

Insert<br />

. 13<br />

JS9R<br />

JS4N Insert<br />

4 J . 04<br />

JS4B<br />

Inser t .19<br />

OPERATING TEMPERATURE RANGE<br />

Neoprene Inserts –55° to 225° F<br />

Polyurethane Inserts –60° to 180° F<br />

Bronze Inserts –60° to 250° F<br />

Neoprene<br />

JS5N Insert<br />

5<br />

JS6N Insert<br />

4<br />

JS7N Insert<br />

9<br />

JS9N Insert<br />

3<br />

Insert Part<br />

Wt.<br />

Lbs.<br />

Polyurethane<br />

. 0 S5U Insert<br />

. 1 S6U Insert<br />

. 3 S7U Insert<br />

1.1<br />

S9U Insert<br />

No.<br />

J 5<br />

J 3<br />

J 9<br />

J 3<br />

Wt.<br />

Lbs.<br />

Bronze<br />

. 0 S5B Insert<br />

. 1 S6B Insert<br />

. 3 S7B Insert<br />

1.1<br />

Wt.<br />

Lbs.<br />

.2<br />

.7<br />

2.0<br />

J 5<br />

J 5<br />

J 0<br />

Table No. 2<br />

<strong>Coupling</strong><br />

Ref. No.<br />

RATING CHART - NORMAL SERVICE <br />

Max.<br />

Bore<br />

Horsepower Capacities at Indicated Speeds<br />

Fin.<br />

Bore Bushed<br />

Typ e 50<br />

100<br />

300<br />

600<br />

900<br />

1200<br />

1800<br />

3600<br />

NEOPRENE INSERTS - For Quiet Service, Normal Duty Applications<br />

JP1,<br />

JZ1<br />

1/<br />

2<br />

- - . 06<br />

. 18<br />

. 36<br />

. 55<br />

. 73<br />

1.<br />

1<br />

2. 0<br />

JP2,<br />

JZ2<br />

3/<br />

4<br />

- - . 08<br />

. 25<br />

. 50<br />

. 75<br />

1.<br />

0<br />

1.<br />

5<br />

2. 8<br />

JP3,<br />

JS3<br />

7/<br />

8<br />

- - . 20<br />

. 60<br />

1.<br />

2<br />

1.<br />

8<br />

2.<br />

4<br />

3.<br />

6<br />

6. 6<br />

JP4,<br />

JS4 1 1/ 8<br />

- - . 33<br />

1.<br />

0<br />

2.<br />

0<br />

3.<br />

0<br />

4.<br />

0<br />

6.<br />

0<br />

11. 0<br />

JP5,<br />

JS5, JS5H 1 11/16<br />

1 1/ 2<br />

- . 69<br />

2.<br />

0<br />

4.<br />

1<br />

6.<br />

1<br />

8.<br />

2<br />

12.<br />

3<br />

22. 7<br />

JS6<br />

& JS6P 1 15/16<br />

1 3/ 4<br />

- 1.<br />

7<br />

5.<br />

1<br />

10.<br />

3<br />

15.<br />

4<br />

20.<br />

5<br />

30.<br />

8<br />

38. 9<br />

JS7<br />

& JS7Q 2 3/ 8 2 11/16<br />

- 3.<br />

1<br />

9.<br />

4<br />

18.<br />

8<br />

28.<br />

1<br />

37.<br />

5<br />

56.<br />

3<br />

71. 1<br />

HS9R<br />

- 3 3/ 4<br />

- 6.<br />

9<br />

20.<br />

7<br />

41.<br />

3<br />

62.<br />

0<br />

73.<br />

3<br />

96.<br />

0<br />

-<br />

POLYURETHANE INSERTS - For Extra Capacity in Medium to High Speed Applications<br />

JP3,<br />

JS3<br />

7/<br />

8<br />

- - . 30<br />

. 90<br />

1.<br />

8<br />

2.<br />

7<br />

3.<br />

6<br />

5.<br />

3<br />

9. 8<br />

JP4,<br />

JS4 1 1/ 8<br />

- - . 50<br />

1.<br />

5<br />

3.<br />

0<br />

4.<br />

5<br />

6.<br />

0<br />

9.<br />

0<br />

16. 6<br />

JP5,<br />

JS5, JS5H 1 11/16<br />

1 1/ 2<br />

- 1.<br />

0<br />

3.<br />

1<br />

6.<br />

2<br />

9.<br />

2<br />

12.<br />

3<br />

18.<br />

5<br />

34. 1<br />

JS6<br />

& JS6P 1 15/16<br />

1 3/ 4<br />

- 2.<br />

6<br />

7.<br />

7<br />

15.<br />

4<br />

23.<br />

1<br />

30.<br />

8<br />

46.<br />

2<br />

58. 4<br />

JS7<br />

& JS7Q 2 3/ 8 2 11/16<br />

- 4.<br />

7<br />

14.<br />

1<br />

28.<br />

1<br />

42.<br />

2<br />

56.<br />

3<br />

84.<br />

4<br />

106. 6<br />

JS9R<br />

- 3 3/ 4<br />

- 10.<br />

4<br />

31.<br />

1<br />

62.<br />

0<br />

93.<br />

0<br />

110.<br />

0<br />

144.<br />

0<br />

-<br />

BRONZE INSERTS - OIL IMPREGNATED - For Low Speed, High Torque Applications 4<br />

JP3,<br />

JS3<br />

7/<br />

8<br />

- . 20<br />

. 40<br />

1.<br />

2<br />

2.<br />

4<br />

3.<br />

6<br />

4.<br />

7<br />

7.<br />

1<br />

-<br />

JP4,<br />

JS4 1 1/ 8<br />

- . 33<br />

. 66<br />

2.<br />

0<br />

4.<br />

0<br />

6.<br />

0<br />

8.<br />

0<br />

12.<br />

0<br />

-<br />

JP5,<br />

JS5, JS5H 1 11/16<br />

1 1/ 2<br />

. 68<br />

1.<br />

4<br />

4.<br />

1<br />

8.<br />

2<br />

12.<br />

3<br />

16.<br />

4<br />

24.<br />

7<br />

-<br />

JS6<br />

& JS6P 1 15/16<br />

1 3/ 4<br />

1.<br />

7<br />

3.<br />

4<br />

10.<br />

3<br />

20.<br />

5<br />

30.<br />

8<br />

41.<br />

1<br />

- -<br />

JS7<br />

& JS7Q 2 3/ 8 2 11/16<br />

3. 2<br />

6.<br />

3<br />

18.<br />

8<br />

37.<br />

5<br />

56.<br />

3<br />

75.<br />

1<br />

- -<br />

Normal Service Ratings are steady, non-reversing, eight hour service per day, with normal starting torque motor. Apply Service Factor per page 37 for more rugged service.<br />

63025 x H.P.<br />

To determine torque in inch pounds at any given speed use formula:<br />

T =<br />

R.P.M.<br />

Neoprene mold designations of S and N are one in the same<br />

<strong>Coupling</strong>s with Bronze Inserts limited to 250 RPM.<br />

Ratings for speeds less than 50 or 100 R.P.M. can be determined by torque value derived from torque formula at 100 R.P.M.<br />

Small shafts in coupling bore range and short key applications may not transmit horsepowers listed above, check shaft and key stress.<br />

Bronze inserts may be noisy on some applications.<br />

42