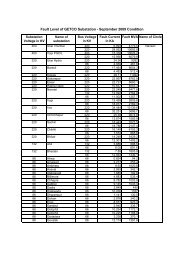

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GETCO/E/TS – XMER01power/R4 Sept <strong>08</strong><br />

1.8.2 Jacking pads shall be provided. It shall be possible to change the directi<strong>on</strong> of the<br />

wheels through 90 0 when the transformer is lifted <strong>on</strong> jacks to permit movement of the<br />

transformer both in l<strong>on</strong>gitudinal and transverse directi<strong>on</strong>. A standard track gauge<br />

(Preferably 1676 mm) in both l<strong>on</strong>gitudinal and transverse directi<strong>on</strong>al shall be<br />

chosen.<br />

1.8.3 Pulling eyes shall be provided to facilitate movement of transformer and they shall be<br />

suitable brazed in a vertical directi<strong>on</strong> so that b<strong>on</strong>ding does not occur when the pull<br />

has a vertical comp<strong>on</strong>ent.<br />

1.9 CORE:<br />

1.9.1 The transformer may be of core or shell type. The core shall be built up with highgrade<br />

n<strong>on</strong>-ageing cold-rolled grain oriented silic<strong>on</strong> steel laminati<strong>on</strong>s having high<br />

permeability and low hystersis loss. The core material shall be prime CRGO, which<br />

shall be procured directly from manufacturer or through accredited marketing<br />

organizati<strong>on</strong> of reputati<strong>on</strong>.<br />

1.9.1(a)<br />

1.9.1(b)<br />

1.9.1(c)<br />

The thickness of laminati<strong>on</strong> shall be 0.27 mm or less. Surface insulati<strong>on</strong> of<br />

laminati<strong>on</strong>s shall be rust resistant and have high inter laminar resistance. Insulati<strong>on</strong><br />

shall withstand annealing temperature as high as 8500 0 C. Insulati<strong>on</strong> shall be<br />

resistant to hot cooling medium. Laminati<strong>on</strong>s are not to be punched.<br />

Bidder should have in house core cutting facility for proper m<strong>on</strong>itoring & c<strong>on</strong>trol <strong>on</strong><br />

quality & also to avoid any possibility of mixing if prime material with<br />

defective/sec<strong>on</strong>d grade material. This should be indicated in variably in the QAP.<br />

The purchaser may witness the core-cutting process. In case the in-house core<br />

cutting facility is not available, then the same shall be carried out in the presence of<br />

the representative of GETCO.<br />

The bidder will offer the core for stage inspecti<strong>on</strong> and get approval from<br />

GETCO during manufacturing stage. The bidder has to produce following<br />

documents at the time of inspecti<strong>on</strong> for c<strong>on</strong>firmati<strong>on</strong> of use of prime core<br />

materials at the time of stage inspecti<strong>on</strong> for c<strong>on</strong>firmati<strong>on</strong> of use of prime<br />

core materials.<br />

i) Invoice of supplier<br />

ii) Mills of approved test certificates<br />

iii) Packing list<br />

iv) Bill of lading<br />

v) Bill of entry certificate by custom.<br />

To avoid any possibility of mixing of ‘Prime material’ with any other sec<strong>on</strong>d grade/<br />

defective material, the imported packed slit coils of CRGO materials shall be opened<br />

in the presence of the GETCO’s representative. Only after the inspecti<strong>on</strong> and<br />

approval from purchaser, the core material will be cut in-house OR sent to external<br />

agency for cutting individual laminati<strong>on</strong>s. In case the core is sent to external agency<br />

Sign and Seal of Bidder Page 11 of 87