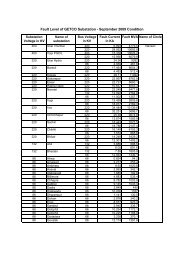

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GETCO/E/TS – XMER01power/R4 Sept <strong>08</strong><br />

INSULATING MATERIAL:<br />

(a) Sample check for physical properties of material.<br />

(b) Check for dielectric strength.<br />

(c) Visual & dimensi<strong>on</strong>al checks.<br />

(d) Sample check <strong>on</strong> insulating paper for pH Value, electric strength.<br />

(e) Check for the reacti<strong>on</strong> of hot oil <strong>on</strong> insulating materials.<br />

(f) Certificati<strong>on</strong> of all tests results.<br />

WINDING:<br />

(a) Sample check <strong>on</strong> winding c<strong>on</strong>ductor for mechanical properties and electrical<br />

c<strong>on</strong>ductivity.<br />

(b) Visual dimensi<strong>on</strong>al checks <strong>on</strong> c<strong>on</strong>ductor for scratches, dent marks etc.<br />

(c) Sample check <strong>on</strong> insulating paper for pH Value, electric strength.<br />

(d) Check for the reacti<strong>on</strong> of hot oil <strong>on</strong> insulating paper.<br />

(e) Check for the b<strong>on</strong>ding of the insulating paper <strong>on</strong> c<strong>on</strong>ductor.<br />

(f)<br />

(g)<br />

(h)<br />

(i)<br />

(j)<br />

(k)<br />

(l)<br />

(m)<br />

Check for absence of short circuit between parallel strands.<br />

Check and ensure that physical c<strong>on</strong>diti<strong>on</strong> of all materials taken for winding is<br />

satisfactory and free of dust.<br />

Check for brazed joints wherever applicable.<br />

Measurement of voltage to be carried out when core/yoke is completely<br />

restacked and all c<strong>on</strong>necti<strong>on</strong>s ready.<br />

C<strong>on</strong>ductor enamel test for checking of cracks, leakage and pin holes<br />

C<strong>on</strong>ductor flexibility test<br />

Heat Shrinkable test for enameled wire<br />

Certificati<strong>on</strong> of all test results<br />

CHECK BEFORE DRYING PROCESS:<br />

(a) Cheek c<strong>on</strong>diti<strong>on</strong>s of insulati<strong>on</strong> in the c<strong>on</strong>ductor and between the windings.<br />

(b) Cheek insulati<strong>on</strong> resistance between high voltage c<strong>on</strong>necti<strong>on</strong> cable and earth<br />

others live parts.<br />

(c) Check insulati<strong>on</strong> resistance between low voltage c<strong>on</strong>necti<strong>on</strong> and earth &<br />

other parts.<br />

(d) Insulati<strong>on</strong> test of core earthing.<br />

(e) Check for proper clean <strong>line</strong>s and absence of dust etc.<br />

(f) Certificati<strong>on</strong> of all test results.<br />

CHECK DURING DRYING PROCESS:<br />

a) Measurement and recording of temperature and drying time during vacuum<br />

treatment.<br />

b) Check for completeness of drying.<br />

c) Certificati<strong>on</strong> of all test results.<br />

ASSEMBLED TRANSFORMER:<br />

Sign and Seal of Bidder Page 29 of 87