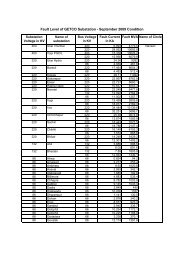

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GETCO/E/TS – XMER01power/R4 Sept <strong>08</strong><br />

1.10 WINDING:<br />

1.10.1 The c<strong>on</strong>ductor for winding shall be of electrolytic grade copper. The winding shall be<br />

so designed that all coil assemblies of identical voltage ratings shall be<br />

interchangeable and field repairs can be readily d<strong>on</strong>e, without special equipment. The<br />

coils shall be supported between adjacent secti<strong>on</strong>s by insulating spacers and the<br />

barriers, bracings and other insulati<strong>on</strong> used in the assembly of the windings shall be<br />

arranged to ensure a free circulati<strong>on</strong> of the oil and to reduce hot sports in the<br />

windings. The insulati<strong>on</strong> paper shall be of high quality and the value of<br />

degree of polymerizati<strong>on</strong> shall not be less than 1200 Pv and the<br />

necessary test certificate shall be submitted al<strong>on</strong>g with the stage<br />

inspecti<strong>on</strong> report. Provisi<strong>on</strong> shall be made in the tank, for taking<br />

sample, in future, of paper for testing purpose and locati<strong>on</strong> shall be<br />

easily accessible and indicated <strong>on</strong> the transformer tank by affixing<br />

special cauti<strong>on</strong> plate.<br />

1.10.2 The insulati<strong>on</strong> of the coils shall be such as to develop the full electrical strength of<br />

the windings. All materials used in the insulati<strong>on</strong> and assembly of the windings shall<br />

be insoluble, n<strong>on</strong>-catalytic and chemically inactive in the hot transformer oil, and<br />

shall not soften or otherwise be adversely affected under the operating c<strong>on</strong>diti<strong>on</strong>s.<br />

1.10.3 All threaded c<strong>on</strong>necti<strong>on</strong>s shall be provided with locking facilities. All leads from the<br />

winding to the terminal board and bushings shall be rigidly supported to prevent<br />

injury from vibrati<strong>on</strong>. Guide tubes shall be used where practicable.<br />

1.10.4 The windings shall be clamped securely in place so that they will not be displaced or<br />

deformed during short circuits. The assembled core and windings shall be vacuum<br />

dried and suitably impregnated before removal from the treating tank. The copper<br />

c<strong>on</strong>ductors used in the coil structure shall be best suited to the requirements and all<br />

permanent current carrying joints in the windings and the leads shall be welded or<br />

braced.<br />

1.10.5 Windings shall be subjected to a shrinkage treatment before final assembly, so that<br />

no further shrinkage occurs during service. Adjustable device shall be provided for<br />

taking up any possible shrinkage of coils in service if required.<br />

1.10.6 The c<strong>on</strong>ductor shall be transposed at sufficient intervals in order to minimize eddy<br />

currents and equalize the distributi<strong>on</strong> of currents and temperature al<strong>on</strong>g the<br />

windings.<br />

1.10.7 The tapping winding shall be provided separately from main winding to minimise the<br />

out of balance forces in the transformer at all voltage ratios.<br />

Sign and Seal of Bidder Page 13 of 87