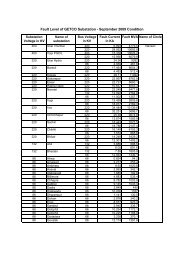

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

220-66-kv-xmer-on-line-nifes-r4-sept-08 - Gujarat Electricity Board

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GETCO/E/TS – XMER01power/R4 Sept <strong>08</strong><br />

transformer will be c<strong>on</strong>nected is 40 kA (sym, rms, 3 phase fault <strong>on</strong> 400, <str<strong>on</strong>g>220</str<strong>on</strong>g> and 132<br />

kV) & 25 kA (sym, rms, 3 phase fault <strong>on</strong> <str<strong>on</strong>g>66</str<strong>on</strong>g>, 22 and 11 kV).<br />

1.6.7 Transformer shall be capable of withstanding thermal and mechanical stresses<br />

caused by symmetrical or asymmetrical faults <strong>on</strong> any winding.<br />

1.7 TANK<br />

1.7.1 The transformer tank and cover or BELL type tank shall be fabricated from<br />

good commercial grade low carb<strong>on</strong> steel suitable for welding and of adequate<br />

thickness. The tank and the cover shall be of welded c<strong>on</strong>structi<strong>on</strong>. All seams shall be<br />

welded and where practicable they shall be double welded. The tank wall shall be<br />

reinforced by stiffener of structural steel for general rigidity. The tank shall have<br />

sufficient strength to withstand without permanent distorti<strong>on</strong> (i) filling by vacuum (ii)<br />

c<strong>on</strong>tinuous internal gas pressure of 0.35 atmosphere with oil at operating level, and<br />

(iii) mechanical shock during transportati<strong>on</strong>. The tank cover shall be bolted to the<br />

tank and the transformer design shall be such that the tank will not be split between<br />

the lower and upper cooler c<strong>on</strong>necti<strong>on</strong> for untanking.<br />

1.7.2 A manhole inspecti<strong>on</strong> window with a welded flange & a bolted cover shall be<br />

provided <strong>on</strong> the tank cover. The manhole shall be of a sufficient size to ease access to<br />

the lower ends of the bushings, terminals etc.<br />

1.7.3 All bolted c<strong>on</strong>necti<strong>on</strong>s to tank shall be fitted with suitable oil-tight gasket, which<br />

shall give satisfactory service under the operating c<strong>on</strong>diti<strong>on</strong>s. Special attenti<strong>on</strong> shall<br />

be given to the methods of making the hot oil-tight joints between the tank and cover<br />

as also between the core and the bushings and all other to ensure that the joints can<br />

be remade satisfactorily and with ease, with the help of semi-skilled labours. Where<br />

compressible gaskets are used, steps shall be provided to prevent over compressi<strong>on</strong>.<br />

Bushings, turrets, cover of accessories, holes and other devices shall be designed to<br />

prevent any leakage of water into or oil from the tank. There should not be any<br />

leakage for three year and this should be guaranteed. All the gaskets to be provided<br />

shall be of RC70C or RC80C grade. Necessary tests certificates from<br />

manufacturer shall be submitted al<strong>on</strong>g with acceptance test report. The<br />

gasket to be used shall not be older than One year.<br />

1.7.4 Suitable guides shall be provided for positi<strong>on</strong>ing the various parts during assembly or<br />

dismantling. Adequate space shall be provided between the covers and windings and<br />

the bottom of the tank for collecti<strong>on</strong> of any sediment.<br />

1.7.5 Lifting eyes or lugs shall be provided <strong>on</strong> all parts of the transformers requiring<br />

independent handling during assembly or dismantling. In additi<strong>on</strong>, the transformer<br />

tank shall be provided with lifting lugs and bosses properly secured to the sides of the<br />

tank for lifting the transformers either by crane or by jacks.<br />

Sign and Seal of Bidder Page 9 of 87