user's manual for corhyd: an internal diffuser hydraulics model - IfH

user's manual for corhyd: an internal diffuser hydraulics model - IfH

user's manual for corhyd: an internal diffuser hydraulics model - IfH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

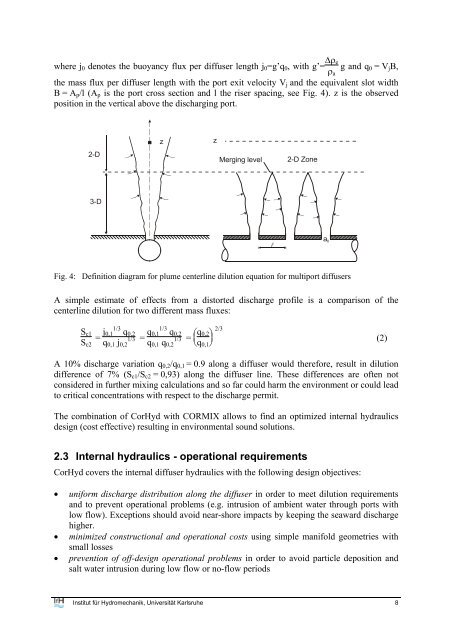

where j 0 denotes the buoy<strong>an</strong>cy flux per <strong>diffuser</strong> length j 0 =g’q 0 , with g’= ∆ρ e<br />

ρ a<br />

g <strong>an</strong>d q 0 = V j B,<br />

the mass flux per <strong>diffuser</strong> length with the port exit velocity V j <strong>an</strong>d the equivalent slot width<br />

B = A p /l (A p is the port cross section <strong>an</strong>d l the riser spacing, see Fig. 4). z is the observed<br />

position in the vertical above the discharging port.<br />

2-D<br />

z<br />

z<br />

Merging level<br />

2-D Zone<br />

3-D<br />

l<br />

a 0<br />

Fig. 4: Definition diagram <strong>for</strong> plume centerline dilution equation <strong>for</strong> multiport <strong>diffuser</strong>s<br />

A simple estimate of effects from a distorted discharge profile is a comparison of the<br />

centerline dilution <strong>for</strong> two different mass fluxes:<br />

S c1<br />

S<br />

= j 0,1 1/3 q 0,2<br />

1/3<br />

c2 q 0,1 j<br />

= q 0,1 1/3 q 0,2<br />

1/3<br />

0,2 q 0,1 q<br />

= ⎜ ⎛<br />

0,2 ⎝<br />

2/3<br />

q 0,2<br />

q 0,1<br />

⎠ ⎟⎞<br />

(2)<br />

A 10% discharge variation q 0,2 /q 0,1 = 0.9 along a <strong>diffuser</strong> would there<strong>for</strong>e, result in dilution<br />

difference of 7% (S c1 /S c2 = 0,93) along the <strong>diffuser</strong> line. These differences are often not<br />

considered in further mixing calculations <strong>an</strong>d so far could harm the environment or could lead<br />

to critical concentrations with respect to the discharge permit.<br />

The combination of CorHyd with CORMIX allows to find <strong>an</strong> optimized <strong>internal</strong> <strong>hydraulics</strong><br />

design (cost effective) resulting in environmental sound solutions.<br />

2.3 Internal <strong>hydraulics</strong> - operational requirements<br />

CorHyd covers the <strong>internal</strong> <strong>diffuser</strong> <strong>hydraulics</strong> with the following design objectives:<br />

• uni<strong>for</strong>m discharge distribution along the <strong>diffuser</strong> in order to meet dilution requirements<br />

<strong>an</strong>d to prevent operational problems (e.g. intrusion of ambient water through ports with<br />

low flow). Exceptions should avoid near-shore impacts by keeping the seaward discharge<br />

higher.<br />

• minimized constructional <strong>an</strong>d operational costs using simple m<strong>an</strong>ifold geometries with<br />

small losses<br />

• prevention of off-design operational problems in order to avoid particle deposition <strong>an</strong>d<br />

salt water intrusion during low flow or no-flow periods<br />

Institut für Hydromech<strong>an</strong>ik, Universität Karlsruhe 8