user's manual for corhyd: an internal diffuser hydraulics model - IfH

user's manual for corhyd: an internal diffuser hydraulics model - IfH

user's manual for corhyd: an internal diffuser hydraulics model - IfH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

numerical methods. The design process there<strong>for</strong>e has to <strong>for</strong>esee a sensitivity <strong>an</strong>alysis to avoid<br />

huge “errors” <strong>an</strong>d to be aware of possible variations.<br />

Influence of <strong>for</strong>mulation inaccuracies<br />

Especially if complex geometries are applied the influence of the <strong>for</strong>mulations <strong>for</strong> loss<br />

coefficients has to be checked carefully. As shown in 2.4.1 all loss <strong>for</strong>mulations are based on<br />

empirical studies mostly calibrated in laboratory investigations. There<strong>for</strong>e it is recommended<br />

to do calculations with additional loss coefficients especially <strong>for</strong> the port/riser configurations<br />

<strong>an</strong>d check whether the influence on <strong>diffuser</strong> per<strong>for</strong>m<strong>an</strong>ce are import<strong>an</strong>t or not. If the influence<br />

is big, it is recommended to do laboratory studies to find better <strong>for</strong>mulations <strong>for</strong> this special<br />

configuration.<br />

Influence of construction imprecision<br />

Submarine construction techniques do not allow <strong>for</strong> precise pipe allocation <strong>an</strong>d precise pipe<br />

fittings. There<strong>for</strong>e loss coefficients calculated out of loss <strong>for</strong>mulations may have uncertainties<br />

due to non-precise siting <strong>an</strong>d fitting of the pipes. Additional losses are resulting out of these<br />

uncertainties. Consequences are higher losses. These c<strong>an</strong> be estimated using the <strong>for</strong>mula from<br />

2.4.1 <strong>for</strong> inaccurate sitings <strong>an</strong>d fittings. Sensitivity studies on these uncertainties allow <strong>for</strong><br />

<strong>an</strong>alysis of maximum total head level.<br />

Varying material properties<br />

Additionally ch<strong>an</strong>ges of materials over time c<strong>an</strong> be considered in further sensitivity<br />

calculations, where pipe roughness values c<strong>an</strong> be increased <strong>an</strong>d <strong>diffuser</strong> per<strong>for</strong>m<strong>an</strong>ce be<br />

<strong>an</strong>alysed (Wood et al, 1993, p. 133). If deposition of solids is expected decreased diameters<br />

allow to <strong>an</strong>alyse <strong>diffuser</strong> per<strong>for</strong>m<strong>an</strong>ce under these condition.<br />

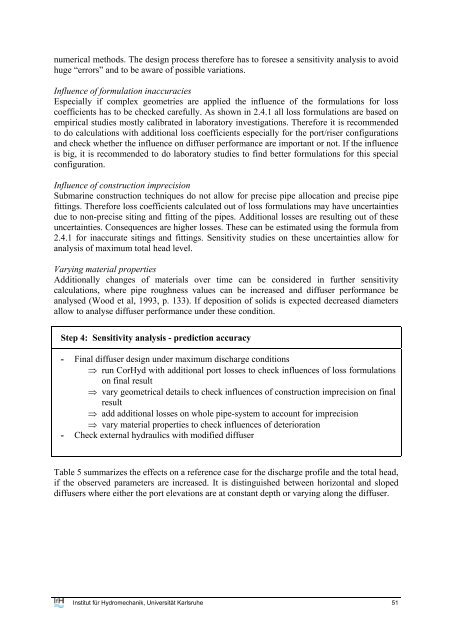

Step 4: Sensitivity <strong>an</strong>alysis - prediction accuracy<br />

- Final <strong>diffuser</strong> design under maximum discharge conditions<br />

⇒ run CorHyd with additional port losses to check influences of loss <strong>for</strong>mulations<br />

on final result<br />

⇒ vary geometrical details to check influences of construction imprecision on final<br />

result<br />

⇒ add additional losses on whole pipe-system to account <strong>for</strong> imprecision<br />

⇒ vary material properties to check influences of deterioration<br />

- Check external <strong>hydraulics</strong> with modified <strong>diffuser</strong><br />

Table 5 summarizes the effects on a reference case <strong>for</strong> the discharge profile <strong>an</strong>d the total head,<br />

if the observed parameters are increased. It is distinguished between horizontal <strong>an</strong>d sloped<br />

<strong>diffuser</strong>s where either the port elevations are at const<strong>an</strong>t depth or varying along the <strong>diffuser</strong>.<br />

Institut für Hydromech<strong>an</strong>ik, Universität Karlsruhe 51