user's manual for corhyd: an internal diffuser hydraulics model - IfH

user's manual for corhyd: an internal diffuser hydraulics model - IfH

user's manual for corhyd: an internal diffuser hydraulics model - IfH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

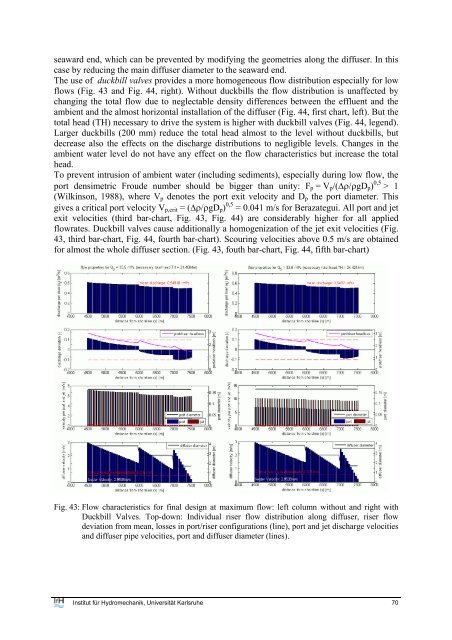

seaward end, which c<strong>an</strong> be prevented by modifying the geometries along the <strong>diffuser</strong>. In this<br />

case by reducing the main <strong>diffuser</strong> diameter to the seaward end.<br />

The use of duckbill valves provides a more homogeneous flow distribution especially <strong>for</strong> low<br />

flows (Fig. 43 <strong>an</strong>d Fig. 44, right). Without duckbills the flow distribution is unaffected by<br />

ch<strong>an</strong>ging the total flow due to neglectable density differences between the effluent <strong>an</strong>d the<br />

ambient <strong>an</strong>d the almost horizontal installation of the <strong>diffuser</strong> (Fig. 44, first chart, left). But the<br />

total head (TH) necessary to drive the system is higher with duckbill valves (Fig. 44, legend).<br />

Larger duckbills (200 mm) reduce the total head almost to the level without duckbills, but<br />

decrease also the effects on the discharge distributions to negligible levels. Ch<strong>an</strong>ges in the<br />

ambient water level do not have <strong>an</strong>y effect on the flow characteristics but increase the total<br />

head.<br />

To prevent intrusion of ambient water (including sediments), especially during low flow, the<br />

port densimetric Froude number should be bigger th<strong>an</strong> unity: F p = V p /(∆ρ/ρgD p ) 0,5 > 1<br />

(Wilkinson, 1988), where V p denotes the port exit velocity <strong>an</strong>d D p the port diameter. This<br />

gives a critical port velocity V p,crit = (∆ρ/ρgD p ) 0,5 = 0.041 m/s <strong>for</strong> Berazategui. All port <strong>an</strong>d jet<br />

exit velocities (third bar-chart, Fig. 43, Fig. 44) are considerably higher <strong>for</strong> all applied<br />

flowrates. Duckbill valves cause additionally a homogenization of the jet exit velocities (Fig.<br />

43, third bar-chart, Fig. 44, fourth bar-chart). Scouring velocities above 0.5 m/s are obtained<br />

<strong>for</strong> almost the whole <strong>diffuser</strong> section. (Fig. 43, fouth bar-chart, Fig. 44, fifth bar-chart)<br />

Fig. 43: Flow characteristics <strong>for</strong> final design at maximum flow: left column without <strong>an</strong>d right with<br />

Duckbill Valves. Top-down: Individual riser flow distribution along <strong>diffuser</strong>, riser flow<br />

deviation from me<strong>an</strong>, losses in port/riser configurations (line), port <strong>an</strong>d jet discharge velocities<br />

<strong>an</strong>d <strong>diffuser</strong> pipe velocities, port <strong>an</strong>d <strong>diffuser</strong> diameter (lines).<br />

Institut für Hydromech<strong>an</strong>ik, Universität Karlsruhe 70