Burn-in & Test Socket Workshop - BiTS Workshop

Burn-in & Test Socket Workshop - BiTS Workshop

Burn-in & Test Socket Workshop - BiTS Workshop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

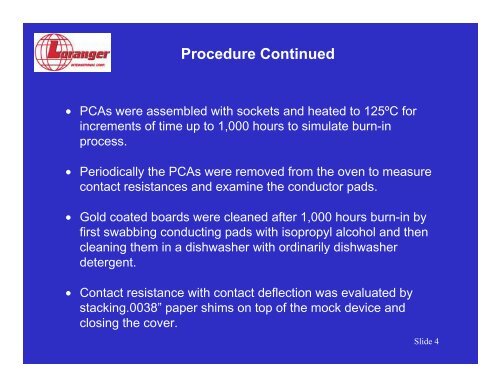

Procedure Cont<strong>in</strong>ued<br />

• PCAs were assembled with sockets and heated to 125ºC for<br />

<strong>in</strong>crements of time up to 1,000 hours to simulate burn-<strong>in</strong><br />

process.<br />

• Periodically the PCAs were removed from the oven to measure<br />

contact resistances and exam<strong>in</strong>e the conductor pads.<br />

• Gold coated boards were cleaned after 1,000 hours burn-<strong>in</strong> by<br />

first swabb<strong>in</strong>g conduct<strong>in</strong>g pads with isopropyl alcohol and then<br />

clean<strong>in</strong>g them <strong>in</strong> a dishwasher with ord<strong>in</strong>arily dishwasher<br />

detergent.<br />

• Contact resistance with contact deflection was evaluated by<br />

stack<strong>in</strong>g.0038” paper shims on top of the mock device and<br />

clos<strong>in</strong>g the cover.<br />

Slide 4