Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

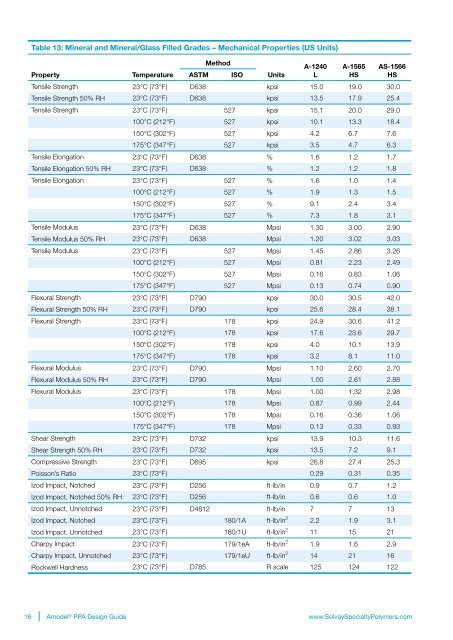

Table 13: Mineral and Mineral/Glass Filled Grades – Mechanical Properties (US Units)<br />

Method<br />

Property Temperature ASTM ISO Units<br />

A-1240<br />

L<br />

A-1565<br />

HS<br />

AS-1566<br />

HS<br />

Tensile Strength 23°C (73°F) D638 kpsi 15.0 19.0 30.0<br />

Tensile Strength 50% RH 23°C (73°F) D638 kpsi 13.5 17.9 25.4<br />

Tensile Strength 23°C (73°F) 527 kpsi 15.1 20.0 29.0<br />

100°C (212°F) 527 kpsi 10.1 13.3 18.4<br />

150°C (302°F) 527 kpsi 4.2 6.7 7.6<br />

175°C (347°F) 527 kpsi 3.5 4.7 6.3<br />

Tensile Elongation 23°C (73°F) D638 % 1.6 1.2 1.7<br />

Tensile Elongation 50% RH 23°C (73°F) D638 % 1.2 1.2 1.8<br />

Tensile Elongation 23°C (73°F) 527 % 1.6 1.0 1.4<br />

100°C (212°F) 527 % 1.9 1.3 1.5<br />

150°C (302°F) 527 % 9.1 2.4 3.4<br />

175°C (347°F) 527 % 7.3 1.8 3.1<br />

Tensile Modulus 23°C (73°F) D638 Mpsi 1.30 3.00 2.90<br />

Tensile Modulus 50% RH 23°C (73°F) D638 Mpsi 1.20 3.02 3.03<br />

Tensile Modulus 23°C (73°F) 527 Mpsi 1.45 2.86 3.26<br />

100°C (212°F) 527 Mpsi 0.81 2.23 2.49<br />

150°C (302°F) 527 Mpsi 0.16 0.83 1.06<br />

175°C (347°F) 527 Mpsi 0.13 0.74 0.90<br />

Flexural Strength 23°C (73°F) D790 kpsi 30.0 30.5 42.0<br />

Flexural Strength 50% RH 23°C (73°F) D790 kpsi 25.6 28.4 38.1<br />

Flexural Strength 23°C (73°F) 178 kpsi 24.9 30.6 41.2<br />

100°C (212°F) 178 kpsi 17.6 23.6 29.7<br />

150°C (302°F) 178 kpsi 4.0 10.1 13.9<br />

175°C (347°F) 178 kpsi 3.2 8.1 11.0<br />

Flexural Modulus 23°C (73°F) D790 Mpsi 1.10 2.60 2.70<br />

Flexural Modulus 50% RH 23°C (73°F) D790 Mpsi 1.00 2.61 2.88<br />

Flexural Modulus 23°C (73°F) 178 Mpsi 1.00 1.32 2.98<br />

100°C (212°F) 178 Mpsi 0.87 0.99 2.44<br />

150°C (302°F) 178 Mpsi 0.16 0.36 1.06<br />

175°C (347°F) 178 Mpsi 0.13 0.33 0.93<br />

Shear Strength 23°C (73°F) D732 kpsi 13.9 10.3 11.6<br />

Shear Strength 50% RH 23°C (73°F) D732 kpsi 13.5 7.2 9.1<br />

Compressive Strength 23°C (73°F) D695 kpsi 26.8 27.4 25.3<br />

Poisson’s Ratio 23°C (73°F) 0.29 0.31 0.35<br />

Izod Impact, Notched 23°C (73°F) D256 ft-lb/in 0.9 0.7 1.2<br />

Izod Impact, Notched 50% RH 23°C (73°F) D256 ft-lb/in 0.6 0.6 1.0<br />

Izod Impact, Unnotched 23°C (73°F) D4812 ft-lb/in 7 7 13<br />

Izod Impact, Notched 23°C (73°F) 180/1A ft-lb/in 2 2.2 1.9 3.1<br />

Izod Impact, Unnotched 23°C (73°F) 180/1U ft-lb/in 2 11 15 21<br />

Charpy Impact 23°C (73°F) 179/1eA ft-lb/in 2 1.9 1.6 2.9<br />

Charpy Impact, Unnotched 23°C (73°F) 179/1eU ft-lb/in 2 14 21 16<br />

Rockwell Hardness 23°C (73°F) D785 R scale 125 124 122<br />

16 Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

www.<strong>Solvay</strong>SpecialtyPolymers.com