Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

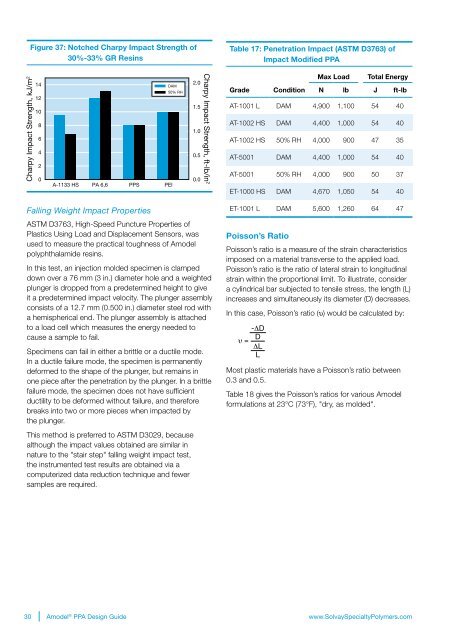

Figure 37: Notched Charpy Impact Strength of<br />

30%-33% GR Resins<br />

Table 17: Penetration Impact (ASTM D3763) of<br />

Impact Modified PPA<br />

Charpy Impact Strength, kJ/m 2<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

A-1133 HS PA 6,6 PPS PEI<br />

DAM<br />

50% RH<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

Charpy Impact Strength, ft-lb/in 2<br />

Max Load Total Energy<br />

Grade Condition N lb J ft-lb<br />

AT-1001 L DAM 4,900 1,100 54 40<br />

AT-1002 HS DAM 4,400 1,000 54 40<br />

AT-1002 HS 50% RH 4,000 900 47 35<br />

AT-5001 DAM 4,400 1,000 54 40<br />

AT-5001 50% RH 4,000 900 50 37<br />

ET-1000 HS DAM 4,670 1,050 54 40<br />

Falling Weight Impact Properties<br />

ASTM D3763, High-Speed Puncture Properties of<br />

<strong>Plastics</strong> Using Load and Displacement Sensors, was<br />

used to measure the practical toughness of Amodel<br />

polyphthalamide resins.<br />

In this test, an injection molded specimen is clamped<br />

down over a 76 mm (3 in.) diameter hole and a weighted<br />

plunger is dropped from a predetermined height to give<br />

it a predetermined impact velocity. The plunger assembly<br />

consists of a 12.7 mm (0.500 in.) diameter steel rod with<br />

a hemispherical end. The plunger assembly is attached<br />

to a load cell which measures the energy needed to<br />

cause a sample to fail.<br />

Specimens can fail in either a brittle or a ductile mode.<br />

In a ductile failure mode, the specimen is permanently<br />

deformed to the shape of the plunger, but remains in<br />

one piece after the penetration by the plunger. In a brittle<br />

failure mode, the specimen does not have sufficient<br />

ductility to be deformed without failure, and therefore<br />

breaks into two or more pieces when impacted by<br />

the plunger.<br />

This method is preferred to ASTM D3029, because<br />

although the impact values obtained are similar in<br />

nature to the "stair step" falling weight impact test,<br />

the instrumented test results are obtained via a<br />

computerized data reduction technique and fewer<br />

samples are required.<br />

ET-1001 L DAM 5,600 1,260 64 47<br />

Poisson’s Ratio<br />

Poisson’s ratio is a measure of the strain characteristics<br />

imposed on a material transverse to the applied load.<br />

Poisson’s ratio is the ratio of lateral strain to longitudinal<br />

strain within the proportional limit. To illustrate, consider<br />

a cylindrical bar subjected to tensile stress, the length (L)<br />

increases and simultaneously its diameter (D) decreases.<br />

In this case, Poisson’s ratio (υ) would be calculated by:<br />

-ΔD<br />

D<br />

υ =<br />

ΔL<br />

L<br />

Most plastic materials have a Poisson’s ratio between<br />

0.3 and 0.5.<br />

Table 18 gives the Poisson’s ratios for various Amodel<br />

formulations at 23°C (73°F), "dry, as molded".<br />

30 Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

www.<strong>Solvay</strong>SpecialtyPolymers.com