Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Since the plastic is constrained, the unit elongation,<br />

combining both thermal expansion and strain, of both<br />

the steel bolt and the plastic, will be as follows:<br />

where<br />

α S<br />

(T F<br />

− T O<br />

) +<br />

F<br />

A S<br />

E S<br />

= α P<br />

(T F<br />

− T O<br />

) −<br />

A S<br />

= cross sectional area of the bolt<br />

A P<br />

= cross sectional area of the washer<br />

E S<br />

= modulus of steel<br />

E P<br />

= modulus of plastic<br />

F = (α P − α S ) (T F − T O ) A S E S<br />

A S<br />

E S<br />

1+<br />

AP E P<br />

F<br />

A P<br />

E P<br />

α S<br />

= coefficient of thermal expansion of steel<br />

α P<br />

= coefficient of thermal expansion of plastic<br />

Solving for F<br />

F = increase in the tensile force of the bolt<br />

and the increase in compressive stress on the plastic<br />

will be:<br />

σ =<br />

F<br />

A P<br />

Loss of Bolt Tightness Due to Creep<br />

When threaded metal fasteners are used to retain or<br />

secure plastic parts to an assembly, and the assembly<br />

is subjected to changes in temperature, the difference<br />

between the thermal expansion coefficients of the metal<br />

and the plastic can cause problems. When a threaded<br />

fastener is tightened, the fastener is elongated slightly and<br />

a compressive stress is generated on the substrate. This<br />

compressive stress maintains the tightness of the bolt.<br />

When the assembly is heated, both the plastic part and<br />

the metal fastener will expand. The plastic part, however,<br />

is constrained by the metal fastener, and cannot expand.<br />

This results in increased compressive stresses in the<br />

plastic, and a corresponding increased tendency for<br />

compressive creep or stress relaxation to occur. The<br />

relaxation of the compressive stress will result in<br />

reduced torque retention in the bolts.<br />

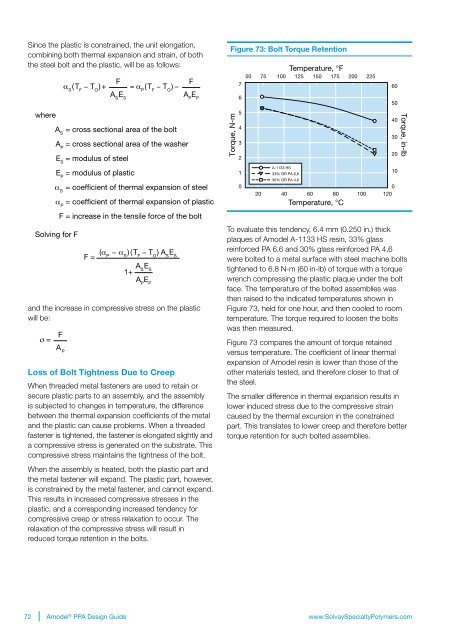

Figure 73: Bolt Torque Retention<br />

Torque, N-m<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

Temperature, °F<br />

50 75 100 125 150 175 200 225<br />

A-1133 HS<br />

33% GR PA 6,6<br />

10<br />

30% GR PA 4,6<br />

0<br />

20 40 60 80 100 120<br />

Temperature, °C<br />

To evaluate this tendency, 6.4 mm (0.250 in.) thick<br />

plaques of Amodel A-1133 HS resin, 33% glass<br />

reinforced PA 6,6 and 30% glass reinforced PA 4,6<br />

were bolted to a metal surface with steel machine bolts<br />

tightened to 6.8 N-m (60 in-lb) of torque with a torque<br />

wrench compressing the plastic plaque under the bolt<br />

face. The temperature of the bolted assemblies was<br />

then raised to the indicated temperatures shown in<br />

Figure 73, held for one hour, and then cooled to room<br />

temperature. The torque required to loosen the bolts<br />

was then measured.<br />

Figure 73 compares the amount of torque retained<br />

versus temperature. The coefficient of linear thermal<br />

expansion of Amodel resin is lower than those of the<br />

other materials tested, and therefore closer to that of<br />

the steel.<br />

The smaller difference in thermal expansion results in<br />

lower induced stress due to the compressive strain<br />

caused by the thermal excursion in the constrained<br />

part. This translates to lower creep and therefore better<br />

torque retention for such bolted assemblies.<br />

60<br />

50<br />

40<br />

30<br />

20<br />

Torque, in-lb<br />

72 Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

www.<strong>Solvay</strong>SpecialtyPolymers.com