Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

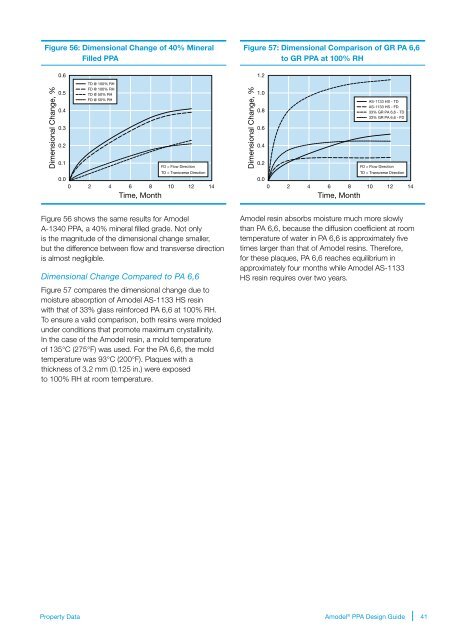

Figure 56: Dimensional Change of 40% Mineral<br />

Filled PPA<br />

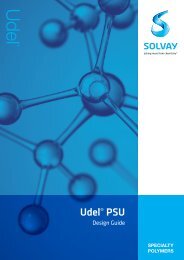

Figure 57: Dimensional Comparison of GR PA 6,6<br />

to GR PPA at 100% RH<br />

Dimensional Change, %<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

TD @ 100% RH<br />

FD @ 100% RH<br />

TD @ 50% RH<br />

FD @ 50% RH<br />

FD = Flow Direction<br />

TD = Transverse Direction<br />

0 2 4 6 8 10 12 14<br />

Time, Month<br />

Dimensional Change, %<br />

1.2<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0.0<br />

AS-1133 HS - TD<br />

AS-1133 HS - FD<br />

33% GR PA 6,6 - TD<br />

33% GR PA 6,6 - FD<br />

FD = Flow Direction<br />

TD = Transverse Direction<br />

0 2 4 6 8 10 12 14<br />

Time, Month<br />

Figure 56 shows the same results for Amodel<br />

A-1340 PPA, a 40% mineral filled grade. Not only<br />

is the magnitude of the dimensional change smaller,<br />

but the difference between flow and transverse direction<br />

is almost negligible.<br />

Dimensional Change Compared to PA 6,6<br />

Figure 57 compares the dimensional change due to<br />

moisture absorption of Amodel AS-1133 HS resin<br />

with that of 33% glass reinforced PA 6,6 at 100% RH.<br />

To ensure a valid comparison, both resins were molded<br />

under conditions that promote maximum crystallinity.<br />

In the case of the Amodel resin, a mold temperature<br />

of 135°C (275°F) was used. For the PA 6,6, the mold<br />

temperature was 93°C (200°F). Plaques with a<br />

thickness of 3.2 mm (0.125 in.) were exposed<br />

to 100% RH at room temperature.<br />

Amodel resin absorbs moisture much more slowly<br />

than PA 6,6, because the diffusion coefficient at room<br />

temperature of water in PA 6,6 is approximately five<br />

times larger than that of Amodel resins. Therefore,<br />

for these plaques, PA 6,6 reaches equilibrium in<br />

approximately four months while Amodel AS-1133<br />

HS resin requires over two years.<br />

Property Data<br />

Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

41