Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Thermal Stability<br />

The general term, thermal stability, is used to describe<br />

the ability of a material to resist loss of properties due<br />

to heat. Various methods are used to evaluate this<br />

tendency. In the next section, we will discuss several<br />

of these methods, including thermogravimetric analysis,<br />

and long-term heat aging.<br />

Thermogravimetric Analysis (TGA)<br />

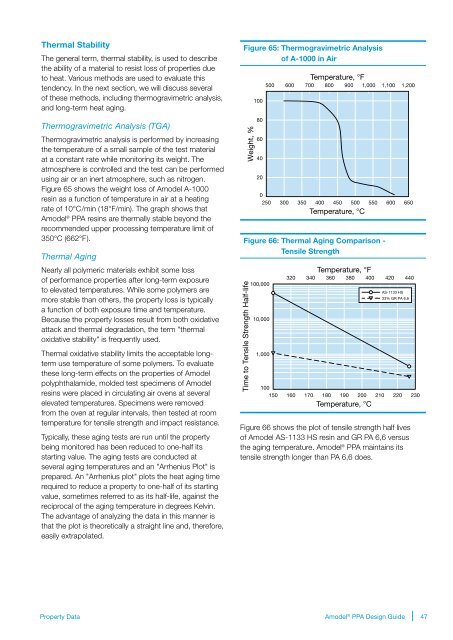

Thermogravimetric analysis is performed by increasing<br />

the temperature of a small sample of the test material<br />

at a constant rate while monitoring its weight. The<br />

atmosphere is controlled and the test can be performed<br />

using air or an inert atmosphere, such as nitrogen.<br />

Figure 65 shows the weight loss of Amodel A-1000<br />

resin as a function of temperature in air at a heating<br />

rate of 10°C/min (18°F/min). The graph shows that<br />

Amodel ® PPA resins are thermally stable beyond the<br />

recommended upper processing temperature limit of<br />

350°C (662°F).<br />

Thermal Aging<br />

Nearly all polymeric materials exhibit some loss<br />

of performance properties after long-term exposure<br />

to elevated temperatures. While some polymers are<br />

more stable than others, the property loss is typically<br />

a function of both exposure time and temperature.<br />

Because the property losses result from both oxidative<br />

attack and thermal degradation, the term "thermal<br />

oxidative stability" is frequently used.<br />

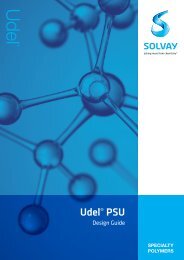

Thermal oxidative stability limits the acceptable longterm<br />

use temperature of some polymers. To evaluate<br />

these long-term effects on the properties of Amodel<br />

polyphthalamide, molded test specimens of Amodel<br />

resins were placed in circulating air ovens at several<br />

elevated temperatures. Specimens were removed<br />

from the oven at regular intervals, then tested at room<br />

temperature for tensile strength and impact resistance.<br />

Typically, these aging tests are run until the property<br />

being monitored has been reduced to one-half its<br />

starting value. The aging tests are conducted at<br />

several aging temperatures and an "Arrhenius Plot" is<br />

prepared. An "Arrhenius plot" plots the heat aging time<br />

required to reduce a property to one-half of its starting<br />

value, sometimes referred to as its half-life, against the<br />

reciprocal of the aging temperature in degrees Kelvin.<br />

The advantage of analyzing the data in this manner is<br />

that the plot is theoretically a straight line and, therefore,<br />

easily extrapolated.<br />

Figure 65: Thermogravimetric Analysis<br />

of A-1000 in Air<br />

Weight, %<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Temperature, °F<br />

500 600 700 800 900 1,000 1,100 1,200<br />

0<br />

250 300 350 400 450 500 550 600 650<br />

Temperature, °C<br />

Figure 66: Thermal Aging Comparison -<br />

Tensile Strength<br />

Time to Tensile Strength Half-life<br />

100,000<br />

10,000<br />

1,000<br />

Temperature, °F<br />

320 340 360 380 400 420 440<br />

100<br />

150 160 170 180 190 200 210 220 230<br />

Temperature, °C<br />

AS-1133 HS<br />

33% GR PA 6,6<br />

Figure 66 shows the plot of tensile strength half lives<br />

of Amodel AS-1133 HS resin and GR PA 6,6 versus<br />

the aging temperature. Amodel ® PPA maintains its<br />

tensile strength longer than PA 6,6 does.<br />

Property Data<br />

Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

47