Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

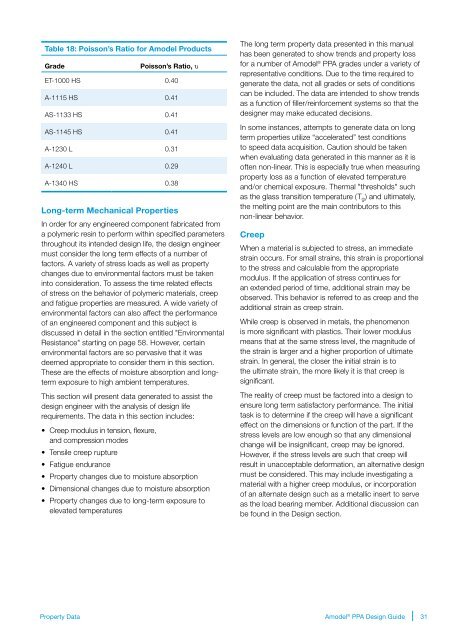

Table 18: Poisson’s Ratio for Amodel Products<br />

Grade<br />

Poisson’s Ratio, υ<br />

ET-1000 HS 0.40<br />

A-1115 HS 0.41<br />

AS-1133 HS 0.41<br />

AS-1145 HS 0.41<br />

A-1230 L 0.31<br />

A-1240 L 0.29<br />

A-1340 HS 0.38<br />

Long-term Mechanical Properties<br />

In order for any engineered component fabricated from<br />

a polymeric resin to perform within specified parameters<br />

throughout its intended design life, the design engineer<br />

must consider the long term effects of a number of<br />

factors. A variety of stress loads as well as property<br />

changes due to environmental factors must be taken<br />

into consideration. To assess the time related effects<br />

of stress on the behavior of polymeric materials, creep<br />

and fatigue properties are measured. A wide variety of<br />

environmental factors can also affect the performance<br />

of an engineered component and this subject is<br />

discussed in detail in the section entitled "Environmental<br />

Resistance" starting on page 58. However, certain<br />

environmental factors are so pervasive that it was<br />

deemed appropriate to consider them in this section.<br />

These are the effects of moisture absorption and longterm<br />

exposure to high ambient temperatures.<br />

This section will present data generated to assist the<br />

design engineer with the analysis of design life<br />

requirements. The data in this section includes:<br />

• Creep modulus in tension, flexure,<br />

and compression modes<br />

• Tensile creep rupture<br />

• Fatigue endurance<br />

• Property changes due to moisture absorption<br />

• Dimensional changes due to moisture absorption<br />

• Property changes due to long-term exposure to<br />

elevated temperatures<br />

The long term property data presented in this manual<br />

has been generated to show trends and property loss<br />

for a number of Amodel ® PPA grades under a variety of<br />

representative conditions. Due to the time required to<br />

generate the data, not all grades or sets of conditions<br />

can be included. The data are intended to show trends<br />

as a function of filler/reinforcement systems so that the<br />

designer may make educated decisions.<br />

In some instances, attempts to generate data on long<br />

term properties utilize “accelerated” test conditions<br />

to speed data acquisition. Caution should be taken<br />

when evaluating data generated in this manner as it is<br />

often non-linear. This is especially true when measuring<br />

property loss as a function of elevated temperature<br />

and/or chemical exposure. Thermal "thresholds" such<br />

as the glass transition temperature (T g ) and ultimately,<br />

the melting point are the main contributors to this<br />

non-linear behavior.<br />

Creep<br />

When a material is subjected to stress, an immediate<br />

strain occurs. For small strains, this strain is proportional<br />

to the stress and calculable from the appropriate<br />

modulus. If the application of stress continues for<br />

an extended period of time, additional strain may be<br />

observed. This behavior is referred to as creep and the<br />

additional strain as creep strain.<br />

While creep is observed in metals, the phenomenon<br />

is more significant with plastics. Their lower modulus<br />

means that at the same stress level, the magnitude of<br />

the strain is larger and a higher proportion of ultimate<br />

strain. In general, the closer the initial strain is to<br />

the ultimate strain, the more likely it is that creep is<br />

significant.<br />

The reality of creep must be factored into a design to<br />

ensure long term satisfactory performance. The initial<br />

task is to determine if the creep will have a significant<br />

effect on the dimensions or function of the part. If the<br />

stress levels are low enough so that any dimensional<br />

change will be insignificant, creep may be ignored.<br />

However, if the stress levels are such that creep will<br />

result in unacceptable deformation, an alternative design<br />

must be considered. This may include investigating a<br />

material with a higher creep modulus, or incorporation<br />

of an alternate design such as a metallic insert to serve<br />

as the load bearing member. Additional discussion can<br />

be found in the <strong>Design</strong> section.<br />

Property Data<br />

Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

31