Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

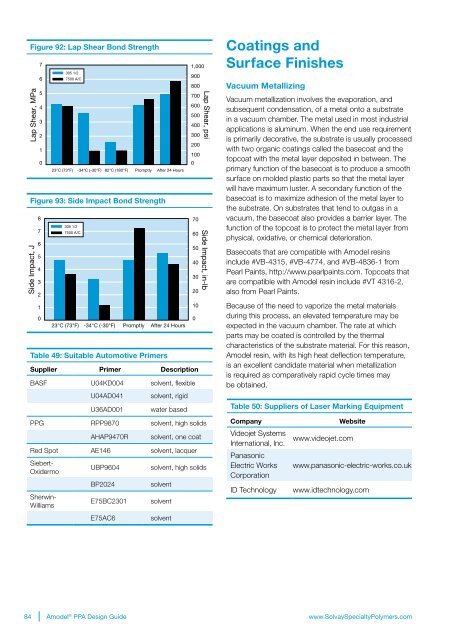

Figure 92: Lap Shear Bond Strength<br />

Lap Shear, MPa<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

305 1/2<br />

7500 A/C<br />

23°C (73°F) -34°C (-30°F) 82°C (180°F) Promptly After 24 Hours<br />

Figure 93: Side Impact Bond Strength<br />

Side Impact, J<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

305 1/2<br />

7500 A/C<br />

23°C (73°F) -34°C (-30°F) Promptly After 24 Hours<br />

1,000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

Table 49: Suitable Automotive Primers<br />

Supplier Primer Description<br />

BASF U04KD004 solvent, flexible<br />

U04AD041 solvent, rigid<br />

U36AD001<br />

water based<br />

PPG RPP9870 solvent, high solids<br />

AHAP9470R<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

solvent, one coat<br />

Red Spot AE146 solvent, lacquer<br />

Siebert-<br />

Oxidermo<br />

UBP9604 solvent, high solids<br />

Sherwin-<br />

Williams<br />

BP2024<br />

E75BC2301<br />

solvent<br />

solvent<br />

Lap Shear, psi<br />

Side Impact, in-lb<br />

Coatings and<br />

Surface Finishes<br />

Vacuum Metallizing<br />

Vacuum metallization involves the evaporation, and<br />

subsequent condensation, of a metal onto a substrate<br />

in a vacuum chamber. The metal used in most industrial<br />

applications is aluminum. When the end use requirement<br />

is primarily decorative, the substrate is usually processed<br />

with two organic coatings called the basecoat and the<br />

topcoat with the metal layer deposited in between. The<br />

primary function of the basecoat is to produce a smooth<br />

surface on molded plastic parts so that the metal layer<br />

will have maximum luster. A secondary function of the<br />

basecoat is to maximize adhesion of the metal layer to<br />

the substrate. On substrates that tend to outgas in a<br />

vacuum, the basecoat also provides a barrier layer. The<br />

function of the topcoat is to protect the metal layer from<br />

physical, oxidative, or chemical deterioration.<br />

Basecoats that are compatible with Amodel resins<br />

include #VB-4315, #VB-4774, and #VB-4836-1 from<br />

Pearl Paints, http://www.pearlpaints.com. Topcoats that<br />

are compatible with Amodel resin include #VT 4316-2,<br />

also from Pearl Paints.<br />

Because of the need to vaporize the metal materials<br />

during this process, an elevated temperature may be<br />

expected in the vacuum chamber. The rate at which<br />

parts may be coated is controlled by the thermal<br />

characteristics of the substrate material. For this reason,<br />

Amodel resin, with its high heat deflection temperature,<br />

is an excellent candidate material when metallization<br />

is required as comparatively rapid cycle times may<br />

be obtained.<br />

Table 50: Suppliers of Laser Marking Equipment<br />

Company<br />

Videojet Systems<br />

International, Inc.<br />

Panasonic<br />

Electric Works<br />

Corporation<br />

ID Technology<br />

Website<br />

www.videojet.com<br />

www.panasonic-electric-works.co.uk<br />

www.idtechnology.com<br />

E75AC6<br />

solvent<br />

84 Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

www.<strong>Solvay</strong>SpecialtyPolymers.com