Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Design Guide - Solvay Plastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Figure 85: Boss <strong>Design</strong> - General <strong>Guide</strong>lines<br />

Figure 86: Thermostat Housing Showing Beads<br />

O.D. = 2 X I.D.<br />

O.D.<br />

I.D.<br />

0.3T T<br />

Undercuts<br />

Some design features, depending on orientation,<br />

can place portions of the mold in the way of ejecting<br />

the part. These features are called undercuts and<br />

can require special mold configurations, such as<br />

slides or cams, to move prior to ejection. In some<br />

cases, the material being molded will have enough<br />

flexibility that the part can be pushed off the undercut<br />

without damage.<br />

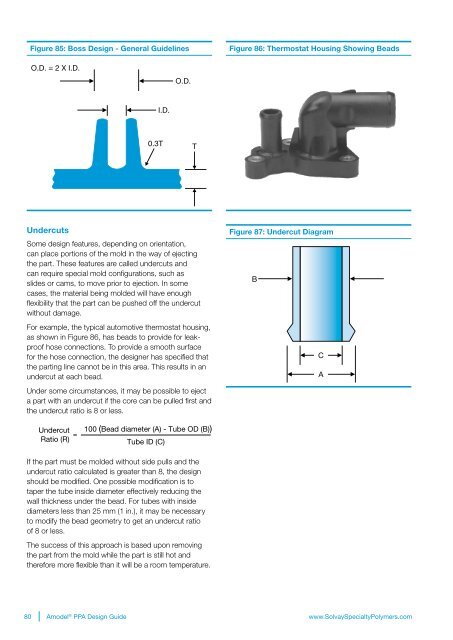

For example, the typical automotive thermostat housing,<br />

as shown in Figure 86, has beads to provide for leakproof<br />

hose connections. To provide a smooth surface<br />

for the hose connection, the designer has specified that<br />

the parting line cannot be in this area. This results in an<br />

undercut at each bead.<br />

Under some circumstances, it may be possible to eject<br />

a part with an undercut if the core can be pulled first and<br />

the undercut ratio is 8 or less.<br />

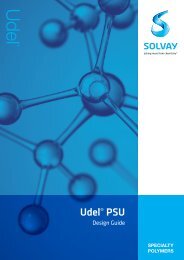

Figure 87: Undercut Diagram<br />

B<br />

C<br />

A<br />

Undercut<br />

Ratio (R)<br />

=<br />

100 (Bead diameter (A) - Tube OD (B))<br />

Tube ID (C)<br />

If the part must be molded without side pulls and the<br />

undercut ratio calculated is greater than 8, the design<br />

should be modified. One possible modification is to<br />

taper the tube inside diameter effectively reducing the<br />

wall thickness under the bead. For tubes with inside<br />

diameters less than 25 mm (1 in.), it may be necessary<br />

to modify the bead geometry to get an undercut ratio<br />

of 8 or less.<br />

The success of this approach is based upon removing<br />

the part from the mold while the part is still hot and<br />

therefore more flexible than it will be a room temperature.<br />

80 Amodel ® PPA <strong>Design</strong> <strong>Guide</strong><br />

www.<strong>Solvay</strong>SpecialtyPolymers.com