Form 20-F 2005

Form 20-F 2005

Form 20-F 2005

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

We remain dedicated to our zero-accident objective. As the establishment of an entirely risk-free industrial environment is nevertheless<br />

impossible, it is vital to prepare and train all of our employees to respond as effectively as possible in the event of an accident or other<br />

crisis. Our objective is to establish and test emergency plans that are tailored to the risks involved for every business and activity.<br />

97% of our businesses have revised and tested their emergency plans over the past three years. Industrial hygiene correspondents<br />

have been appointed to coordinate industrial initiatives and to ensure the execution of risk evaluations at all of our sites. These risk<br />

evaluations involve, among other things, identifying chemical, biological, physical and ergonomic hazards, as well as estimating<br />

exposure levels and assessing short-, medium- and long-term risks.<br />

We seek to improve our safety record on an ongoing basis. This requires daily individual commitment by all of our employees,<br />

especially our managers. Accordingly, members of the Executive Committee inspect our sites without prior warning. The results<br />

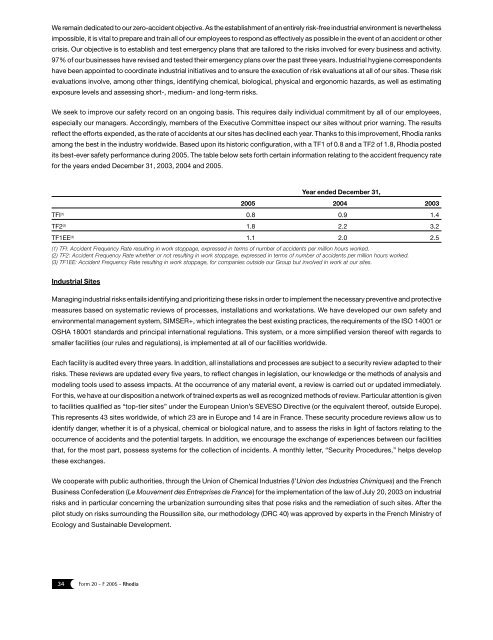

reflect the efforts expended, as the rate of accidents at our sites has declined each year. Thanks to this improvement, Rhodia ranks<br />

among the best in the industry worldwide. Based upon its historic configuration, with a TF1 of 0.8 and a TF2 of 1.8, Rhodia posted<br />

its best-ever safety performance during <strong>20</strong>05. The table below sets forth certain information relating to the accident frequency rate<br />

for the years ended December 31, <strong>20</strong>03, <strong>20</strong>04 and <strong>20</strong>05.<br />

Year ended December 31,<br />

<strong>20</strong>05 <strong>20</strong>04 <strong>20</strong>03<br />

TFI (1) 0.8 0.9 1.4<br />

TF2 (2) 1.8 2.2 3.2<br />

TF1EE (3) 1.1 2.0 2.5<br />

(1) TFI: Accident Frequency Rate resulting in work stoppage, expressed in terms of number of accidents per million hours worked.<br />

(2) TF2: Accident Frequency Rate whether or not resulting in work stoppage, expressed in terms of number of accidents per million hours worked.<br />

(3) TF1EE: Accident Frequency Rate resulting in work stoppage, for companies outside our Group but involved in work at our sites.<br />

Industrial Sites<br />

Managing industrial risks entails identifying and prioritizing these risks in order to implement the necessary preventive and protective<br />

measures based on systematic reviews of processes, installations and workstations. We have developed our own safety and<br />

environmental management system, SIMSER+, which integrates the best existing practices, the requirements of the ISO 14001 or<br />

OSHA 18001 standards and principal international regulations. This system, or a more simplified version thereof with regards to<br />

smaller facilities (our rules and regulations), is implemented at all of our facilities worldwide.<br />

Each facility is audited every three years. In addition, all installations and processes are subject to a security review adapted to their<br />

risks. These reviews are updated every five years, to reflect changes in legislation, our knowledge or the methods of analysis and<br />

modeling tools used to assess impacts. At the occurrence of any material event, a review is carried out or updated immediately.<br />

For this, we have at our disposition a network of trained experts as well as recognized methods of review. Particular attention is given<br />

to facilities qualified as “top-tier sites” under the European Union’s SEVESO Directive (or the equivalent thereof, outside Europe).<br />

This represents 43 sites worldwide, of which 23 are in Europe and 14 are in France. These security procedure reviews allow us to<br />

identify danger, whether it is of a physical, chemical or biological nature, and to assess the risks in light of factors relating to the<br />

occurrence of accidents and the potential targets. In addition, we encourage the exchange of experiences between our facilities<br />

that, for the most part, possess systems for the collection of incidents. A monthly letter, “Security Procedures,” helps develop<br />

these exchanges.<br />

We cooperate with public authorities, through the Union of Chemical Industries (l’Union des Industries Chimiques) and the French<br />

Business Confederation (Le Mouvement des Entreprises de France) for the implementation of the law of July <strong>20</strong>, <strong>20</strong>03 on industrial<br />

risks and in particular concerning the urbanization surrounding sites that pose risks and the remediation of such sites. After the<br />

pilot study on risks surrounding the Roussillon site, our methodology (DRC 40) was approved by experts in the French Ministry of<br />

Ecology and Sustainable Development.<br />

34 <strong>Form</strong> <strong>20</strong> - F <strong>20</strong>05 - Rhodia