Xstrata Copper North Queensland.pdf - Mount Isa Mines

Xstrata Copper North Queensland.pdf - Mount Isa Mines

Xstrata Copper North Queensland.pdf - Mount Isa Mines

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Workplace health and safety<br />

Job Role Criteria (JRC)<br />

Throughout 2010 the JRC tool has been<br />

refined and developed into an interactive<br />

web-based resource. The role library grew to<br />

over 240 roles across our north <strong>Queensland</strong><br />

operations and the expansion of the current<br />

evidence base to include Thermal Work Limit,<br />

Manual Task Risk Matrix, and Whole Body<br />

Vibration data. Please refer to the case study<br />

on page 55 for an update on the JRC.<br />

Earth Moving Equipment<br />

Safety Round Table<br />

Since 2008 we have provided the Earth<br />

Moving Equipment Safety Round Table<br />

(EMESRT) Underground Hard Rock mining<br />

group with input into its vision, purpose,<br />

scope and annual action plans.<br />

The group saw developments in 2010 with<br />

the four initial design philosophies being<br />

broadened to 15. The mining industry utilises<br />

communication from EMESRT in relation to<br />

design philosophies and reference points<br />

for Original Equipment Manufacturers when<br />

designing and redesigning existing equipment<br />

used in mining operations. This has increased<br />

the understanding of and influenced design<br />

considerations in the areas of ergonomic<br />

equipment design, noise, working at<br />

heights, fire, dust, isolation, visibility/collision<br />

avoidance, machine stability, guarding, whole<br />

of body vibration, controls/displays, tyres,<br />

manual handling, and equipment access.<br />

EMESRT now includes representation from<br />

major mining companies and equipment<br />

providers. Through EMESRT, <strong>Xstrata</strong> <strong>Copper</strong><br />

<strong>North</strong> <strong>Queensland</strong> continues to work in<br />

partnership with Caterpillar and Sandvik and<br />

other underground, earthmoving, drilling and<br />

surface exploration equipment providers.<br />

The EMESRT forum provides an opportunity<br />

for open dialogue aimed at improving our<br />

equipment’s usability and reducing the risks<br />

inherent with their design.<br />

case study<br />

Bulk density weighing unit<br />

At the <strong>Mount</strong> <strong>Isa</strong> <strong>Mines</strong> copper operations, bulk density weighing<br />

is conducted to measure the weight in air and in water of diamond<br />

drill core to determine its bulk density.<br />

The practice of bulk density weighing<br />

using a manual methodology is common<br />

throughout the mining industry. This<br />

method requires significant manual handling<br />

of core samples and the movement of large<br />

quantities of water, exposing personnel to a<br />

range of potential workplace hazards.<br />

In 2008, <strong>Mount</strong> <strong>Isa</strong> <strong>Mines</strong> copper<br />

operations developed a solution to several<br />

critical issues associated with the manual<br />

process of bulk density weighing. These<br />

issues involved a work environment that<br />

required significant manual handling of core<br />

samples, often at poor angles, and also<br />

required the movement of large quantities<br />

of water causing both manual handling and<br />

slip hazards.<br />

Secondly, the data recording process was<br />

done by hand transfer of weights to a paper<br />

sample sheet. The hand written weights<br />

were then transferred to a computer<br />

spreadsheet and loaded to the computer<br />

network, resulting in increased time to<br />

complete the work as data was recorded<br />

multiple times.<br />

Thirdly, there were data quality issues as the<br />

method was repetitive and often prone to<br />

error when conducted over the course of<br />

a shift, often resulting in data transfer and<br />

input errors.<br />

A new bulk density weighing unit was<br />

designed to address these issues. This<br />

resulted in an integrated work platform<br />

with a clear path in and out to handle the<br />

core sample volumes being tested on a<br />

regular basis; a motorised lift system for<br />

the weighing basket and the water tank<br />

to reduce the manual handling issues of<br />

lowering samples in and out of the water<br />

tank; a pumping system to remove the<br />

water from the tanks, and to control the<br />

water level in the tank; and a digital scale<br />

and laptop computer included in the unit<br />

enabling data to be recorded just once and<br />

minimising transfer errors.<br />

<strong>Xstrata</strong>’s Manager, Strategic Mine Planning,<br />

Nathan Bullock said the design of a new<br />

bulk density weighing unit had provided a<br />

number of safety and operational benefits<br />

to the <strong>Mount</strong> <strong>Isa</strong> <strong>Mines</strong> copper operations.<br />

“The unit is set up so that there is less<br />

handling of core samples and it has<br />

eliminated the need for personnel to<br />

bend and reach like they used to with the<br />

previous method and also reduced the<br />

likelihood of muscle strains and repetitive<br />

motion injuries,” said Nathan.<br />

<strong>Mount</strong> <strong>Isa</strong> <strong>Mines</strong> <strong>Copper</strong> Operations<br />

invested $31,500 for each unit, and two<br />

units were fully operational by early 2009.<br />

Project work undertaken during 2010 has<br />

shown the introduction of the bulk density<br />

weigh unit has improved the quality of data<br />

collected from the stations. Additionally,<br />

with an incident and injury free year at the<br />

core shed in 2010 the project highlights the<br />

benefits of undertaking operational safety<br />

improvements in the workplace.<br />

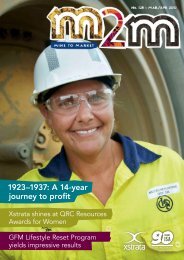

Rachael Schultz – Core Shed Technician,<br />

operates the Bulk Density Unit<br />

34 XSTRATA COPPER NORTH QUEENSLAND