Barley for Food and Health: Science, Technology, and Products

Barley for Food and Health: Science, Technology, and Products

Barley for Food and Health: Science, Technology, and Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WHOLE-GRAIN PROCESSING 107<br />

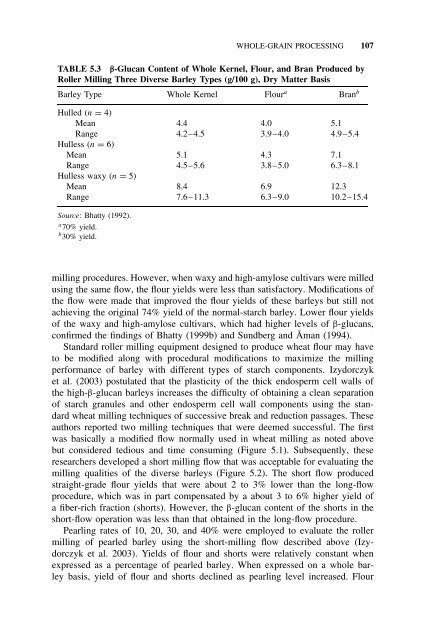

TABLE 5.3 β-Glucan Content of Whole Kernel, Flour, <strong>and</strong> Bran Produced by<br />

Roller Milling Three Diverse <strong>Barley</strong> Types (g/100 g), Dry Matter Basis<br />

<strong>Barley</strong> Type Whole Kernel Flour a Bran b<br />

Hulled (n = 4)<br />

Mean 4.4 4.0 5.1<br />

Range 4.2–4.5 3.9–4.0 4.9–5.4<br />

Hulless (n = 6)<br />

Mean 5.1 4.3 7.1<br />

Range 4.5–5.6 3.8–5.0 6.3–8.1<br />

Hulless waxy (n = 5)<br />

Mean 8.4 6.9 12.3<br />

Range 7.6–11.3 6.3–9.0 10.2–15.4<br />

Source: Bhatty (1992).<br />

a 70% yield.<br />

b 30% yield.<br />

milling procedures. However, when waxy <strong>and</strong> high-amylose cultivars were milled<br />

using the same flow, the flour yields were less than satisfactory. Modifications of<br />

the flow were made that improved the flour yields of these barleys but still not<br />

achieving the original 74% yield of the normal-starch barley. Lower flour yields<br />

of the waxy <strong>and</strong> high-amylose cultivars, which had higher levels of β-glucans,<br />

confirmed the findings of Bhatty (1999b) <strong>and</strong> Sundberg <strong>and</strong> Åman (1994).<br />

St<strong>and</strong>ard roller milling equipment designed to produce wheat flour may have<br />

to be modified along with procedural modifications to maximize the milling<br />

per<strong>for</strong>mance of barley with different types of starch components. Izydorczyk<br />

et al. (2003) postulated that the plasticity of the thick endosperm cell walls of<br />

the high-β-glucan barleys increases the difficulty of obtaining a clean separation<br />

of starch granules <strong>and</strong> other endosperm cell wall components using the st<strong>and</strong>ard<br />

wheat milling techniques of successive break <strong>and</strong> reduction passages. These<br />

authors reported two milling techniques that were deemed successful. The first<br />

was basically a modified flow normally used in wheat milling as noted above<br />

but considered tedious <strong>and</strong> time consuming (Figure 5.1). Subsequently, these<br />

researchers developed a short milling flow that was acceptable <strong>for</strong> evaluating the<br />

milling qualities of the diverse barleys (Figure 5.2). The short flow produced<br />

straight-grade flour yields that were about 2 to 3% lower than the long-flow<br />

procedure, which was in part compensated by a about 3 to 6% higher yield of<br />

a fiber-rich fraction (shorts). However, the β-glucan content of the shorts in the<br />

short-flow operation was less than that obtained in the long-flow procedure.<br />

Pearling rates of 10, 20, 30, <strong>and</strong> 40% were employed to evaluate the roller<br />

milling of pearled barley using the short-milling flow described above (Izydorczyk<br />

et al. 2003). Yields of flour <strong>and</strong> shorts were relatively constant when<br />

expressed as a percentage of pearled barley. When expressed on a whole barley<br />

basis, yield of flour <strong>and</strong> shorts declined as pearling level increased. Flour