- Page 1 and 2:

Electromagnetic Testing Study Guide

- Page 3 and 4:

E&P Applications Charlie Chong/ Fio

- Page 5 and 6:

Charlie Chong/ Fion Zhang

- Page 7 and 8:

乱 七 八 糟 - 随 看 随 记 C

- Page 9 and 10:

Charlie Chong/ Fion Zhang

- Page 11 and 12:

Charlie Chong/ Fion Zhang http://ww

- Page 13 and 14:

IVONA TTS Capable. Charlie Chong/ F

- Page 15 and 16:

EDDY CURRENT an Overview Descriptio

- Page 17 and 18:

Tangential Probe Charlie Chong/ Fio

- Page 19 and 20:

Electromagnetic Testing Advantages

- Page 21 and 22:

Factors Affecting Eddy Current Resp

- Page 23 and 24:

from this it can be seen that depth

- Page 25 and 26:

http://www.eng.morgan.edu/~hubert/I

- Page 27 and 28:

Robotic Charlie Chong/ Fion Zhang

- Page 29 and 30:

Measurement Techniques (EN!) a) Abs

- Page 31 and 32:

Figure 1.1 Arago’s Experiment Cha

- Page 33 and 34:

Oersted discovered the presence of

- Page 35 and 36:

Figure 1.3: Induced current electro

- Page 37 and 38:

Charlie Chong/ Fion Zhang http://en

- Page 39 and 40:

Charlie Chong/ Fion Zhang http://en

- Page 41 and 42:

The law of physics describing the p

- Page 43 and 44:

Charlie Chong/ Fion Zhang http://hy

- Page 45 and 46:

Magnetic Force The magnetic field B

- Page 47 and 48:

Generation of Eddy Currents When a

- Page 49 and 50:

Factors Affecting Inductance There

- Page 51 and 52:

COIL LENGTH: All other factors bein

- Page 53 and 54:

Coil Inductance L An approximation

- Page 55 and 56:

Note the direction of the primary c

- Page 57 and 58:

Generation of Eddy Current With a p

- Page 59 and 60:

Charlie Chong/ Fion Zhang Permeabil

- Page 61 and 62:

A Dual Variable inductors Figure 1:

- Page 63 and 64:

Figure 3: Here is another inductor

- Page 65 and 66:

Figure 4: The two inductors on this

- Page 67 and 68:

Grundig radio satellit 750 ■ http

- Page 69 and 70:

Figure 1.7: Phasor Diagram of Coil

- Page 71 and 72:

Current Density The distribution of

- Page 73 and 74:

Figure 1.8: Relative eddy current d

- Page 75 and 76:

Relative Magnetic Permeability Perm

- Page 77 and 78:

It should be observed at this point

- Page 79 and 80:

δ = (π x 100 x 10 3 x 4 x π x 0.

- Page 81 and 82:

Using 1.35 mm as depth x from surfa

- Page 83 and 84:

Standard Depth for Different Conduc

- Page 85 and 86:

Current (?) Lagging Voltage lagging

- Page 87 and 88:

σº∙πμ■δ∝∞ωΩθ√ρβ

- Page 89 and 90:

Figure 1.9 should be used as a rela

- Page 91 and 92:

Figure 1.8: Relative eddy current d

- Page 93 and 94:

Q.1.1 Generation of eddy currents d

- Page 95 and 96:

Q.1.5 Eddy current generated a test

- Page 97 and 98:

Q.1.9 Refer to Figure1.9 using exam

- Page 99 and 100:

Chapter 2 The Coil Arrangements Cha

- Page 101 and 102:

Probe coils and probe coil forms ca

- Page 103 and 104:

Encircling Coils Encircling coil, o

- Page 105 and 106:

Discussion Subject; Encircling Coil

- Page 107 and 108:

Bobbin Coils Bobbin coil, inside di

- Page 109 and 110:

Figure 2.5: Test coil configuration

- Page 111 and 112:

Differential coils Differential coi

- Page 113 and 114:

Figure 2.6: External reference diff

- Page 115 and 116:

Figure 2.7: Hybrid coil (through tr

- Page 117 and 118:

Additional Coil Characteristics Coi

- Page 119 and 120:

Q.2.1 Differential coils are usuall

- Page 121 and 122:

Q.2.6 An absolute coil measurement

- Page 123 and 124:

The Answers Charlie Chong/ Fion Zha

- Page 125 and 126:

As discussed earlier test coil desi

- Page 127 and 128:

Demonstration model of a moving iro

- Page 129 and 130:

Thus, the resistance of a 10 ft len

- Page 131 and 132:

SPECIFIC RESISTANCE OR RESISTIVITY

- Page 133 and 134:

Problem: What is the resistance of

- Page 135 and 136:

The inductance of a multilayer air

- Page 137 and 138:

Example: A coil whose dimensions ar

- Page 139 and 140:

Example: Using the 32 μH coil calc

- Page 141 and 142:

Impedance To explain the addition o

- Page 143 and 144:

Maximum transfer of power is accomp

- Page 145 and 146:

Rectangular Notation Because reacta

- Page 147 and 148:

Vectors With Polar Notations. Stand

- Page 149 and 150:

Rectangular Notation - Prefix “j

- Page 151 and 152:

Imaginary Component In “rectangul

- Page 153 and 154:

Imaginary Charlie Chong/ Fion Zhang

- Page 155 and 156:

To convert from rectangular to pola

- Page 157 and 158:

More Reading on Polar & Rectangular

- Page 159 and 160:

Eddy current coils with included im

- Page 161 and 162:

Permeability and Shielding Effects

- Page 163 and 164:

Another technique of shielding uses

- Page 165 and 166:

Saturation Approach Another coil de

- Page 167 and 168:

Figure 3.5: Magnetic bias probe Cha

- Page 169 and 170:

Materials must be chemically compat

- Page 171 and 172:

Q.3.1 A coil's resistance is determ

- Page 173 and 174:

Q.3.7 The Q or merit of a coil is d

- Page 175 and 176:

The Answers Charlie Chong/ Fion Zha

- Page 177 and 178:

Jackfruit Tree Charlie Chong/ Fion

- Page 179 and 180:

Electrical Conductivity σ In elect

- Page 181 and 182:

As previously discussed, conductivi

- Page 183 and 184:

Figure 4.1; Conductivity curve Char

- Page 185 and 186:

The coil's inductive reactance is r

- Page 187 and 188:

Effects of Heat Treatment on Conduc

- Page 189 and 190:

Permeability Permeability of any ma

- Page 191 and 192:

When increases in the magnetizing f

- Page 193 and 194:

Skin Effect Charlie Chong/ Fion Zha

- Page 195 and 196:

Discussion Subject: Response to the

- Page 197 and 198:

Lift Off Electromagnetic coupling b

- Page 199 and 200:

Fill factor will always be a number

- Page 201 and 202:

Figure 4.4: Fill factor ratios When

- Page 203 and 204:

Example: Calculate the resultant lo

- Page 205 and 206:

Figure 1.8 is again useful to illus

- Page 207 and 208:

Signal-to-Noise Ratio Signal-to-noi

- Page 209 and 210:

The Answers Charlie Chong/ Fion Zha

- Page 211 and 212:

Q.4.4 A (?) prime factor affecting

- Page 213 and 214:

Q.4.10 Temperature changes, vibrati

- Page 215 and 216:

Test Frequencies It is the responsi

- Page 217 and 218:

Single Frequency Systems Unfortunat

- Page 219 and 220:

Eddy Current Density Since the sens

- Page 221 and 222:

Applicable Scenario Eddy Current De

- Page 223 and 224:

Standard Depth δ Formula The depth

- Page 225 and 226:

Example 1: As an example of how thi

- Page 227 and 228:

Frequency Selection - Ferromagnetic

- Page 229 and 230:

A frequency can always selected to

- Page 231 and 232:

Figure 5.1(a) shows the effect on p

- Page 233 and 234:

Figure 5.1: Effects of frequency ch

- Page 235 and 236:

Figure 5.2: Normalized impedance di

- Page 237 and 238:

Figure 5.3: Impedance variations ca

- Page 239 and 240:

Figure 5.4: Impedance variations ca

- Page 241 and 242:

Multiparameter Techniques It become

- Page 243 and 244:

Multiparameter Techniques - Multipl

- Page 245 and 246:

First, a frequency is selected to g

- Page 247 and 248:

More Reading on Characteristic Para

- Page 249 and 250:

Figure 1: Eddy Current Testing Char

- Page 251 and 252:

Figure 2: Types of Probes Charlie C

- Page 253 and 254:

Surface (Pancake) Probes Surface pr

- Page 255 and 256:

Encircling Probes Encircling probes

- Page 257 and 258:

Design of eddy current probes In mo

- Page 259 and 260:

In brief, probe design is usually d

- Page 261 and 262:

Analytical Approach (Pc & f g ) Ana

- Page 263 and 264:

RECENT TRENDS IN EDDY CURRENT PROBE

- Page 265 and 266:

Pressurized Heavy Water Reactors (P

- Page 267 and 268:

The Answers Charlie Chong/ Fion Zha

- Page 269 and 270:

Q.5.4 Calculate the limit frequency

- Page 271 and 272:

Q.5.7 Primary resistance is subtrac

- Page 273 and 274:

Q5.9 A 25% deep crack open to the n

- Page 275 and 276:

Chapter 6 Instrument Systems Charli

- Page 277 and 278:

Eddy Current Instrumentation Most o

- Page 279 and 280:

Figure 6.1: Internal functions of t

- Page 281 and 282:

Chernobyl Nuclear Power Plant Charl

- Page 283 and 284:

Figure 6.2: Four types of simple ed

- Page 285 and 286:

Figure 6.2(b) shows an impedance br

- Page 287 and 288:

Figure 6.2(d) illustrates a balanci

- Page 289 and 290:

Eddy current testing - Signal Analy

- Page 291 and 292:

Impedance Testing With impedance ma

- Page 293 and 294:

Phase Analysis Testing - Vector Poi

- Page 295 and 296:

Phase Analysis Testing - Ellipse As

- Page 297 and 298:

Figure 6.4: Cathode ray tube displa

- Page 299 and 300:

Figure 6.5: Screen image of a linea

- Page 301 and 302:

Impedance Plane Testing - Mode of O

- Page 303 and 304:

Figure 6.6: Null balance instrument

- Page 305 and 306:

Figure 6.7: Typical surface riding

- Page 307 and 308:

For deep subsurface crack detection

- Page 309 and 310:

Multiple circuits are used througho

- Page 311 and 312:

This type of digital instrumentatio

- Page 313 and 314:

Figure 6.1: Internal functions of t

- Page 315 and 316:

Read Out Mechanisms - Audio Alarms

- Page 317 and 318:

An qualitative meter response could

- Page 319 and 320:

Figure 6.13: A qualitative analog m

- Page 321 and 322:

Read Out Mechanisms - Cathode Ray T

- Page 323 and 324:

Figure 6.14: Numerical readouts/dig

- Page 325 and 326:

Read Out Mechanisms - Computer Eddy

- Page 327 and 328:

Figure 6.1: Internal functions of t

- Page 329 and 330:

Probe Delivery System Instead of mo

- Page 331 and 332:

Chapter 6 Review Questions Charlie

- Page 333 and 334:

Q.6.1 Signal preparation is usually

- Page 335 and 336:

Q.6.7 Amplitude gates provide a tec

- Page 337 and 338:

Chapter 7 Eddy Current Applications

- Page 339 and 340:

Discontinuity Detection The theoret

- Page 341 and 342:

Heat Exchanger Charlie Chong/ Fion

- Page 343 and 344:

Heat Exchanger Charlie Chong/ Fion

- Page 345 and 346:

Heat Exchanger Charlie Chong/ Fion

- Page 347 and 348: Heat Exchanger Charlie Chong/ Fion

- Page 349 and 350: Heat Exchanger TSP Charlie Chong/ F

- Page 351 and 352: Heat Exchanger TSP Charlie Chong/ F

- Page 353 and 354: Figure 7.2: Phase-to-depth calibrat

- Page 355 and 356: The geometry of real discontinuitie

- Page 357 and 358: Figure 7.5: A multifrequency applic

- Page 359 and 360: Aerospace Applications Charlie Chon

- Page 361 and 362: The reference specimen and its asso

- Page 363 and 364: Dimensional Measurements Dimensiona

- Page 365 and 366: Figure 7.6: A single frequency hard

- Page 367 and 368: Conductivity Measurements Conductiv

- Page 369 and 370: Alloy Sorting Alloy sorting can als

- Page 371 and 372: In addition, it is advisable to hav

- Page 373 and 374: Answers Charlie Chong/ Fion Zhang

- Page 375 and 376: Q.7.4 Using multifrequency techniqu

- Page 377 and 378: Q.7.7 Response to multilayer varyin

- Page 379 and 380: Chapter 8 Other Electromagnetic Tec

- Page 381 and 382: Some other technologies that have b

- Page 383 and 384: Alternating current field measureme

- Page 385 and 386: Figure 8.1 shows the basic principl

- Page 387 and 388: ACFM Principle Charlie Chong/ Fion

- Page 389 and 390: ACFM Z X Bx =magnetic flux componen

- Page 391 and 392: Alternating current field measureme

- Page 393 and 394: The technique in its simplest form

- Page 395 and 396: Alternating current field measureme

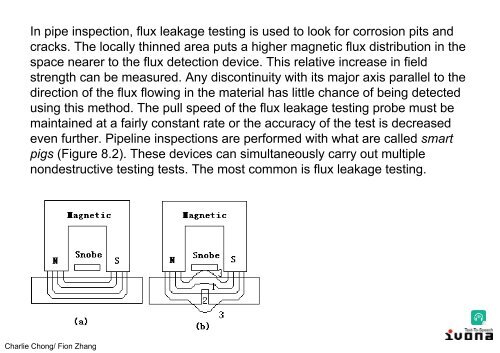

- Page 397: Magnetic Flux Leakage Testing Prima

- Page 401 and 402: Magnetic Flux Leakage Testing Charl

- Page 403 and 404: The most commonly used inservice in

- Page 405 and 406: Magnetic Saturation Charlie Chong/

- Page 407 and 408: The magnetization curve is not retr

- Page 409 and 410: Magnetic Flux Leakage Testing Charl

- Page 411 and 412: Magnetic Flux Leakage The basic pri

- Page 413 and 414: Magnetic Flux Leakage Magnetic Flux

- Page 415 and 416: Special hybrid (driver/pick up) coi

- Page 417 and 418: At distances in excess of two tube

- Page 419 and 420: Figure 8.4: Remote field testing en

- Page 421 and 422: Remote-Field Energy Zones - in remo

- Page 423 and 424: Remote-Field Zone Transition Zone C

- Page 425 and 426: RFT - Flux distribution in pipe (a)

- Page 427 and 428: Remote Field Zone - The third defin

- Page 429 and 430: Amplitude (voltage) - The remote fi

- Page 431 and 432: RFT Charlie Chong/ Fion Zhang http:

- Page 433 and 434: The Remote Field Technique is an el

- Page 435 and 436: Remote Field Eddy Current Technique

- Page 437 and 438: More Reading: RFT Remote Field Test

- Page 439 and 440: These eddy currents, in turn, produ

- Page 441 and 442: The Zones Direct Couple Zone The re

- Page 443 and 444: RFT Probes Probes for inspection of

- Page 445 and 446: RFT Signal Interpretation The signa

- Page 447 and 448: RFT Reference Standards Reference s

- Page 449 and 450:

Answers Charlie Chong/ Fion Zhang

- Page 451 and 452:

Q.8.4 A generally accepted definiti

- Page 453 and 454:

Q.8.8 The region of intense electro

- Page 455 and 456:

Chapter 9 Eddy Current Procedures,

- Page 457 and 458:

American Society for Testing and Ma

- Page 459 and 460:

Military Standard The United States

- Page 461 and 462:

EDDY CURRENT INSPECTION OF NONFERRO

- Page 463 and 464:

. Probe positioning and feeding sha

- Page 465 and 466:

3. Tube Inspection General (Refer t

- Page 467 and 468:

F. INSPECTION RESULTS AND DOCUMENTA

- Page 469 and 470:

G. REFERENCES The following documen

- Page 471 and 472:

Answers Charlie Chong/ Fion Zhang

- Page 473 and 474:

Q.9.4 Military Standards are design

- Page 475 and 476:

Q.9.10 The system in QA3 is calibra

- Page 477 and 478:

More Reading http://www.allaboutcir

- Page 479 and 480:

Discussion Subject: discuss on the

- Page 481 and 482:

Charlie Chong/ Fion Zhang

- Page 483 and 484:

Inspection from the Tube OD Most AS

- Page 485 and 486:

Approximately 25 years ago, the AST

- Page 487 and 488:

One additional advantage of OD ECT

- Page 489 and 490:

The baseline eddy current test The

- Page 491 and 492:

There is no standard accept/reject

- Page 493 and 494:

Pulsed Eddy Currents Systems Charli

- Page 495 and 496:

Although still an active research f

- Page 497 and 498:

LOI (Lift-Off point of Intersection

- Page 499 and 500:

Gap Point : Similar to the LOI, the

- Page 501 and 502:

Driving Coil Charlie Chong/ Fion Zh

- Page 503 and 504:

Hall effect sensors In opposition t

- Page 505 and 506:

Crack Detection using Pulsed Eddy C

- Page 507 and 508:

Fig. 1 (a) ARMANDA - Automated scan

- Page 509 and 510:

Fig. 2. Images of the Eddy current

- Page 511 and 512:

Reading 2: 4.9.2.3 Pulsed Eddy Curr

- Page 513 and 514:

Good Luck Charlie Chong/ Fion Zhang