- Page 1 and 2:

Investigating carotenoid loss after

- Page 3 and 4:

DECLARATION I certify that this wor

- Page 5 and 6:

ACKNOWLEDGEMENTS I am deeply gratef

- Page 7 and 8:

CONTENTS CHAPTER 1.! LITERATURE REV

- Page 9 and 10:

4.3.2! Effect of trial and sweet po

- Page 11 and 12:

1.1 BACKGROUND 1.1.1 Introduction C

- Page 13 and 14:

3 1. Literature review It is estima

- Page 15 and 16:

5 1. Literature review food corresp

- Page 17 and 18:

- the leaves that make energy and s

- Page 19 and 20:

9 1. Literature review Uganda and M

- Page 21 and 22:

11 1. Literature review communicati

- Page 23 and 24:

13 1. Literature review soya grains

- Page 25 and 26:

15 1. Literature review Drying is a

- Page 27 and 28:

17 1. Literature review Modelling o

- Page 29 and 30:

19 1. Literature review Other types

- Page 31 and 32:

21 1. Literature review The perform

- Page 33 and 34:

23 1. Literature review degradation

- Page 35 and 36:

25 1. Literature review carotene an

- Page 37 and 38:

27 1. Literature review (Rees, NRI,

- Page 39 and 40:

29 1. Literature review red (>800 n

- Page 41 and 42:

31 1. Literature review Figure 1-17

- Page 43 and 44:

33 1. Literature review induced by

- Page 45 and 46: 35 1. Literature review Enzymatic c

- Page 47 and 48: 37 1. Literature review Volatile pr

- Page 49 and 50: 39 1. Literature review Carotenoid

- Page 51 and 52: Table 1-5: Effect of type of proces

- Page 53 and 54: Comparison of losses in drying proc

- Page 55 and 56: 45 1. Literature review observed we

- Page 57 and 58: 47 1. Literature review Different p

- Page 59 and 60: Oxygen 49 1. Literature review Oxyg

- Page 61 and 62: 51 1. Literature review the storage

- Page 63 and 64: 2.2.2 Root samples 53 2. Assessment

- Page 65 and 66: 2.2.5 Water activity 55 2. Assessme

- Page 67 and 68: 57 2. Assessment of Methods below t

- Page 69 and 70: 59 2. Assessment of Methods !-carot

- Page 71 and 72: 61 2. Assessment of Methods indicat

- Page 73 and 74: 63 2. Assessment of Methods were we

- Page 75 and 76: 65 2. Assessment of Methods Table 2

- Page 77 and 78: 67 2. Assessment of Methods Intra-l

- Page 79 and 80: 69 2. Assessment of Methods Signifi

- Page 81 and 82: 71 2. Assessment of Methods Table 2

- Page 83 and 84: Content (µg/g) Content (µg/g) Con

- Page 85 and 86: 75 2. Assessment of Methods way-ANO

- Page 87 and 88: 77 2. Assessment of Methods puree.

- Page 89 and 90: Percentage loss "a" redness 45% 40%

- Page 91 and 92: CHAPTER 3. 81 3. Preliminary study

- Page 93 and 94: 83 3. Preliminary study Figure 3-1:

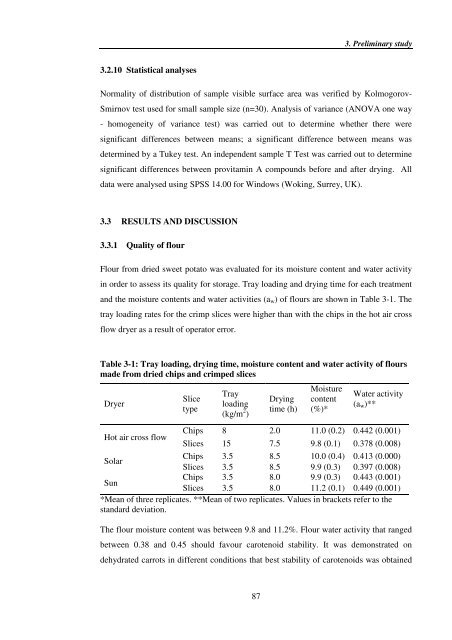

- Page 95: 85 3. Preliminary study Air velocit

- Page 99 and 100: 89 3. Preliminary study because it

- Page 101 and 102: Sample area (cm2) 91 3. Preliminary

- Page 103 and 104: Figure 3-9: UV-Visible spectrum of

- Page 105 and 106: 95 3. Preliminary study Mulokozi an

- Page 107 and 108: 97 3. Preliminary study One hundred

- Page 109 and 110: 99 4. Ugandan field study respectiv

- Page 111 and 112: Transmittance (%) 101 4. Ugandan fi

- Page 113 and 114: 4.2.5 Total carotenoids extraction

- Page 115 and 116: 105 4. Ugandan field study The dryi

- Page 117 and 118: 107 4. Ugandan field study individu

- Page 119 and 120: 109 4. Ugandan field study values a

- Page 121 and 122: 111 4. Ugandan field study caroteno

- Page 123 and 124: 113 4. Ugandan field study observed

- Page 125 and 126: 115 4. Ugandan field study OFSP chi

- Page 127 and 128: 117 5. Mozambican field study carot

- Page 129 and 130: 119 5. Mozambican field study kg (p

- Page 131 and 132: 121 5. Mozambican field study Table

- Page 133 and 134: 123 5. Mozambican field study carot

- Page 135 and 136: Tot. carotenoid content (!g/g) Tot.

- Page 137 and 138: 127 5. Mozambican field study 5.3.6

- Page 139 and 140: a b c c 129 5. Mozambican field stu

- Page 141 and 142: 131 5. Mozambican field study Table

- Page 143 and 144: 133 5. Mozambican field study #-car

- Page 145 and 146: 135 5. Mozambican field study carot

- Page 147 and 148:

CHAPTER 6. 137 6. Effect of pre-tre

- Page 149 and 150:

139 6. Effect of pre-treatment out

- Page 151 and 152:

141 6. Effect of pre-treatment afte

- Page 153 and 154:

143 6. Effect of pre-treatment leve

- Page 155 and 156:

145 6. Effect of pre-treatment Citr

- Page 157 and 158:

147 6. Effect of pre-treatment trea

- Page 159 and 160:

149 6. Effect of pre-treatment inte

- Page 161 and 162:

CHAPTER 7. 151 7. Involvement of en

- Page 163 and 164:

7.2.2. pH measurement 153 7. Involv

- Page 165 and 166:

155 7. Involvement of enzymes glyce

- Page 167 and 168:

157 7. Involvement of enzymes Table

- Page 169 and 170:

159 7. Involvement of enzymes carot

- Page 171 and 172:

161 7. Involvement of enzymes carot

- Page 173 and 174:

163 7. Involvement of enzymes Perox

- Page 175 and 176:

CHAPTER 8. 165 8. Study under contr

- Page 177 and 178:

Kilner jar (with metal lever catch

- Page 179 and 180:

Figure 8-2: Storage system for wate

- Page 181 and 182:

8.2.4 Carotenoid analyses 171 8. St

- Page 183 and 184:

8.3 RESULTS & DISCUSSION 8.3.1 Samp

- Page 185 and 186:

175 8. Study under controlled condi

- Page 187 and 188:

177 8. Study under controlled condi

- Page 189 and 190:

179 8. Study under controlled condi

- Page 191 and 192:

181 8. Study under controlled condi

- Page 193 and 194:

k (day-1) k (day-1) 0.10 0.08 0.06

- Page 195 and 196:

185 8. Study under controlled condi

- Page 197 and 198:

187 8. Study under controlled condi

- Page 199 and 200:

189 8. Study under controlled condi

- Page 201 and 202:

191 8. Study under controlled condi

- Page 203 and 204:

193 8. Study under controlled condi

- Page 205 and 206:

CHAPTER 9. GENERAL DISCUSSION AND F

- Page 207 and 208:

197 9. Discussion carotene loss aft

- Page 209 and 210:

199 9. Discussion total carotenoids

- Page 211 and 212:

9.4.2 Varietal influence 201 9. Dis

- Page 213 and 214:

203 9. Discussion 2008). The side e

- Page 215 and 216:

205 9. Discussion Absence of cis-is

- Page 217 and 218:

207 9. Discussion (Chapter 7). Howe

- Page 219 and 220:

209 9. Discussion of these cultivar

- Page 221 and 222:

References 211 References Aguayo, V

- Page 223 and 224:

213 References Bechoff, A., Dhuique

- Page 225 and 226:

215 References Chen, H.E., Peng, H.

- Page 227 and 228:

DIAS (2006) Semi-Annual and Annual

- Page 229 and 230:

219 References Tropical Agriculture

- Page 231 and 232:

221 References has a positive effec

- Page 233 and 234:

223 References Kamiya N. and Nagamu

- Page 235 and 236:

Lee, S.B. and Kim, K.J. (1995) Effe

- Page 237 and 238:

227 References Mills, R.C. and Hart

- Page 239 and 240:

Nestel, P., Bouis, H.E., Meenakshi,

- Page 241 and 242:

231 References Preston, C.M. and Ba

- Page 243 and 244:

Simon, P.W. (1997) Plant pigments f

- Page 245 and 246:

235 References Tran, T.H., Nguyen,

- Page 247 and 248:

237 References Walter, W.M., Purcel

- Page 249 and 250:

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! A

- Page 251 and 252:

Arrhenius model: = ∞ − Ea RT ek

- Page 253 and 254:

242 Appendix 1 B/Calculation of Arr

- Page 255 and 256:

Temperature is integrated for each

- Page 257 and 258:

2) Integration of temperature in Ug

- Page 259 and 260:

Appendix 2b: Dryers cost in Lualua,

- Page 261 and 262:

250 Appendix 2 Technical informatio

- Page 263 and 264:

252 Appendix 2 Technical informatio

- Page 265 and 266:

Open air flat and sloped dryers 254

- Page 267 and 268:

Appendix 3: Total carotenoids metho

- Page 269 and 270:

4. Partition - Pour 40 ml of Petrol

- Page 271 and 272:

Publications: Publications, award a