Beer & A Better World - Anheuser-Busch InBev

Beer & A Better World - Anheuser-Busch InBev

Beer & A Better World - Anheuser-Busch InBev

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

environmental Performance<br />

At <strong>InBev</strong> Deutschland, we continually seek to<br />

operate more efficiently and maintain our quality<br />

standards, while considering our environmental<br />

impacts, in order to be better stewards of the world<br />

in which we live. We focus our environmental<br />

sustainability initiatives on key issues — water,<br />

energy, recycling and packaging.<br />

Our beers are brewed with natural ingredients,<br />

we use pure water in the brewing process, and<br />

we package and distribute our products for<br />

the enjoyment of our consumers. In addition<br />

to being efficient and reducing waste — which<br />

is an important part of our culture — we also<br />

recognize we have a role to play in addressing<br />

shared challenges such as climate change.<br />

2012 environmental Targets<br />

In 2009, we set targets on key measures such as<br />

water and energy use, as well as carbon emission<br />

reductions, that we will strive to achieve by the<br />

end of 2012. Our 2012 global companywide<br />

targets are:<br />

• Increase our waste and by-product recycling<br />

to 99 percent.<br />

• Reduce water use for beer and soft drinks<br />

plants to an industry leading 3.5 hl/hl.<br />

• Reduce energy use per hectoliter<br />

by 10 percent.<br />

• Reduce CO2<br />

emissions per hectoliter<br />

by 10 percent.<br />

improving environmental Performance<br />

<strong>InBev</strong> Deutschland is making significant<br />

contributions to achieving these goals.<br />

• In 2009, <strong>InBev</strong> Deutschland recycled<br />

99.2 percent of our waste and brewing<br />

by-products.<br />

• In 2009, our water usage was 3.98 hectoliters<br />

per hectoliter of production.<br />

• In 2009, <strong>InBev</strong> Deutschland reduced energy<br />

consumption per hectoliter of production<br />

by 2 percent.<br />

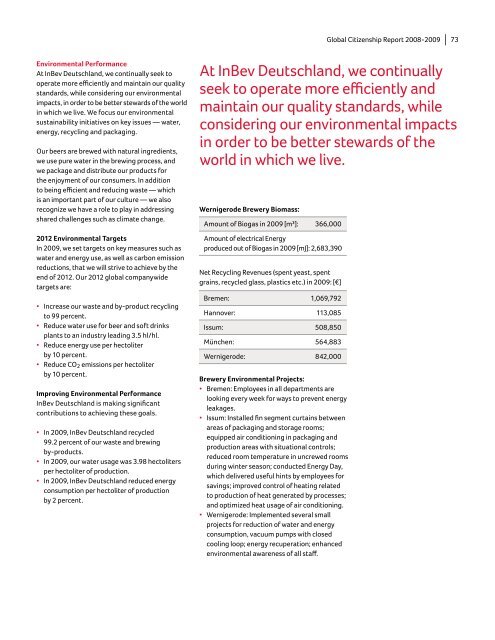

Wernigerode brewery biomass:<br />

Net Recycling Revenues (spent yeast, spent<br />

grains, recycled glass, plastics etc.) in 2009: [€]<br />

brewery environmental Projects:<br />

• Bremen: Employees in all departments are<br />

looking every week for ways to prevent energy<br />

leakages.<br />

• Issum: Installed fin segment curtains between<br />

areas of packaging and storage rooms;<br />

equipped air conditioning in packaging and<br />

production areas with situational controls;<br />

reduced room temperature in uncrewed rooms<br />

during winter season; conducted Energy Day,<br />

which delivered useful hints by employees for<br />

savings; improved control of heating related<br />

to production of heat generated by processes;<br />

and optimized heat usage of air conditioning.<br />

• Wernigerode: Implemented several small<br />

projects for reduction of water and energy<br />

consumption, vacuum pumps with closed<br />

cooling loop; energy recuperation; enhanced<br />

environmental awareness of all staff.<br />

Global Citizenship Report 2008-2009 | 73<br />

At <strong>InBev</strong> Deutschland, we continually<br />

seek to operate more efficiently and<br />

maintain our quality standards, while<br />

considering our environmental impacts<br />

in order to be better stewards of the<br />

world in which we live.<br />

Amount of Biogas in 2009 [m³]: 366,000<br />

Amount of electrical Energy<br />

produced out of Biogas in 2009 [mJ]: 2,683,390<br />

Bremen: 1,069,792<br />

Hannover: 113,085<br />

Issum: 508,850<br />

München: 564,883<br />

Wernigerode: 842,000