BoostAero XML and CSV Implementation Guideline ... - SupplyOn

BoostAero XML and CSV Implementation Guideline ... - SupplyOn

BoostAero XML and CSV Implementation Guideline ... - SupplyOn

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

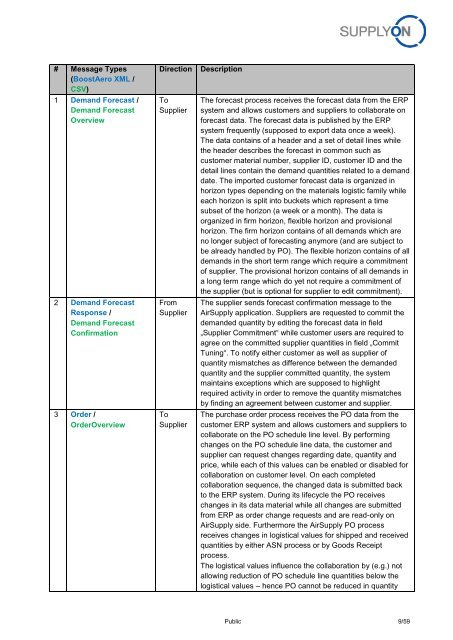

# Message Types(<strong>BoostAero</strong> <strong>XML</strong> /<strong>CSV</strong>)1 Dem<strong>and</strong> Forecast /Dem<strong>and</strong> ForecastOverview2 Dem<strong>and</strong> ForecastResponse /Dem<strong>and</strong> ForecastConfirmation3 Order /OrderOverviewDirectionToSupplierFromSupplierToSupplierDescriptionThe forecast process receives the forecast data from the ERPsystem <strong>and</strong> allows customers <strong>and</strong> suppliers to collaborate onforecast data. The forecast data is published by the ERPsystem frequently (supposed to export data once a week).The data contains of a header <strong>and</strong> a set of detail lines whilethe header describes the forecast in common such ascustomer material number, supplier ID, customer ID <strong>and</strong> thedetail lines contain the dem<strong>and</strong> quantities related to a dem<strong>and</strong>date. The imported customer forecast data is organized inhorizon types depending on the materials logistic family whileeach horizon is split into buckets which represent a timesubset of the horizon (a week or a month). The data isorganized in firm horizon, flexible horizon <strong>and</strong> provisionalhorizon. The firm horizon contains of all dem<strong>and</strong>s which areno longer subject of forecasting anymore (<strong>and</strong> are subject tobe already h<strong>and</strong>led by PO). The flexible horizon contains of alldem<strong>and</strong>s in the short term range which require a commitmentof supplier. The provisional horizon contains of all dem<strong>and</strong>s ina long term range which do yet not require a commitment ofthe supplier (but is optional for supplier to edit commitment).The supplier sends forecast confirmation message to theAirSupply application. Suppliers are requested to commit thedem<strong>and</strong>ed quantity by editing the forecast data in field„Supplier Commitment“ while customer users are required toagree on the committed supplier quantities in field „CommitTuning“. To notify either customer as well as supplier ofquantity mismatches as difference between the dem<strong>and</strong>edquantity <strong>and</strong> the supplier committed quantity, the systemmaintains exceptions which are supposed to highlightrequired activity in order to remove the quantity mismatchesby finding an agreement between customer <strong>and</strong> supplier.The purchase order process receives the PO data from thecustomer ERP system <strong>and</strong> allows customers <strong>and</strong> suppliers tocollaborate on the PO schedule line level. By performingchanges on the PO schedule line data, the customer <strong>and</strong>supplier can request changes regarding date, quantity <strong>and</strong>price, while each of this values can be enabled or disabled forcollaboration on customer level. On each completedcollaboration sequence, the changed data is submitted backto the ERP system. During its lifecycle the PO receiveschanges in its data material while all changes are submittedfrom ERP as order change requests <strong>and</strong> are read-only onAirSupply side. Furthermore the AirSupply PO processreceives changes in logistical values for shipped <strong>and</strong> receivedquantities by either ASN process or by Goods Receiptprocess.The logistical values influence the collaboration by (e.g.) notallowing reduction of PO schedule line quantities below thelogistical values – hence PO cannot be reduced in quantityPublic 9/59