36 Drying of Wood

36 Drying of Wood

36 Drying of Wood

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

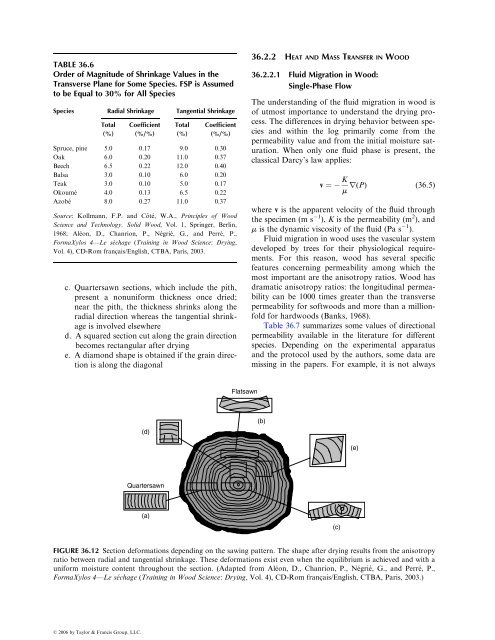

TABLE <strong>36</strong>.6Order <strong>of</strong> Magnitude <strong>of</strong> Shrinkage Values in theTransverse Plane for Some Species. FSP is Assumedto be Equal to 30% for All SpeciesSpecies Radial Shrinkage Tangential ShrinkageTotal(%)Coefficient(%/%)Total(%)Coefficient(%/%)Spruce, pine 5.0 0.17 9.0 0.30Oak 6.0 0.20 11.0 0.37Beech 6.5 0.22 12.0 0.40Balsa 3.0 0.10 6.0 0.20Teak 3.0 0.10 5.0 0.17Okoumé 4.0 0.13 6.5 0.22Azobé 8.0 0.27 11.0 0.37Source: Kollmann, F.P. and Côté, W.A., Principles <strong>of</strong> <strong>Wood</strong>Science and Technology, Solid <strong>Wood</strong>, Vol. 1, Springer, Berlin,1968; Aléon, D., Chanrion, P., Négrié, G., and Perré, P.,FormaXylos 4—Le séchage (Training in <strong>Wood</strong> Science: <strong>Drying</strong>,Vol. 4), CD-Rom français/English, CTBA, Paris, 2003.c. Quartersawn sections, which include the pith,present a nonuniform thickness once dried;near the pith, the thickness shrinks along theradial direction whereas the tangential shrinkageis involved elsewhered. A squared section cut along the grain directionbecomes rectangular after dryinge. A diamond shape is obtained if the grain directionis along the diagonal<strong>36</strong>.2.2 HEAT AND MASS T RANSFER IN WOOD<strong>36</strong>.2.2 .1 Flui d Migration in <strong>Wood</strong>:Singl e-Phase FlowThe understanding <strong>of</strong> the fluid migration in wood is<strong>of</strong> utmost importance to understand the drying process.The differences in drying behavior between speciesand within the log primarily come from thepermeability value and from the initial moisture saturation.When only one fluid phase is present, theclassical Darcy’s law applies:v ¼ K r(P) (<strong>36</strong>:5)mwhere v is the apparent velocity <strong>of</strong> the fluid throughthe specimen (m s 1 ), K is the permeability (m 2 ), andm is the dynamic viscosity <strong>of</strong> the fluid (Pa s 1 ).Fluid migration in wood uses the vascular systemdeveloped by trees for their physiological requirements.For this reason, wood has several specificfeatures concerning permeability among which themost important are the anisotropy ratios. <strong>Wood</strong> hasdramatic anisotropy ratios: the longitudinal permeabilitycan be 1000 times greater than the transversepermeability for s<strong>of</strong>twoods and more than a millionfoldfor hardwoods (Banks, 1968).Table <strong>36</strong>.7 summarizes some values <strong>of</strong> directionalpermeability available in the literature for differentspecies. Depending on the experimental apparatusand the protocol used by the authors, some data aremissing in the papers. For example, it is not alwaysFlatsawn(d)(b)(e)Quartersawn(a)(c)FIGURE <strong>36</strong>.12 Section deformations depending on the sawing pattern. The shape after drying results from the anisotropyratio between radial and tangential shrinkage. These deformations exist even when the equilibrium is achieved and with auniform moisture content throughout the section. (Adapted from Aléon, D., Chanrion, P., Négrié, G., and Perré, P.,FormaXylos 4—Le séchage (Training in <strong>Wood</strong> Science: <strong>Drying</strong>, Vol. 4), CD-Rom français/English, CTBA, Paris, 2003.)ß 2006 by Taylor & Francis Group, LLC.