36 Drying of Wood

36 Drying of Wood

36 Drying of Wood

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

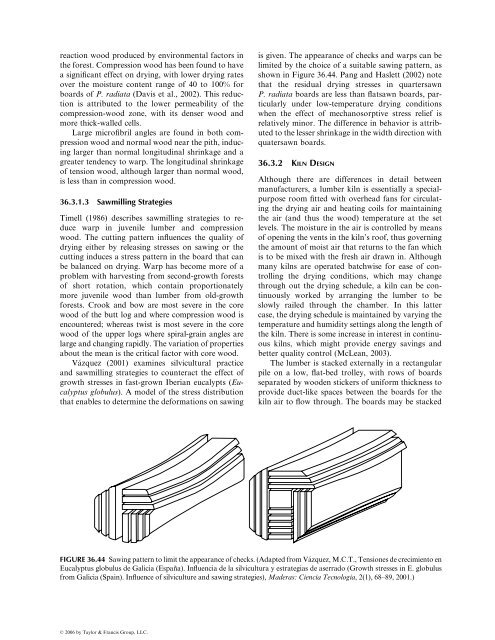

eaction wood produced by environmental factors inthe forest. Compression wood has been found to havea significant effect on drying, with lower drying ratesover the moisture content range <strong>of</strong> 40 to 100% forboards <strong>of</strong> P. radiata (Davis et al., 2002). This reductionis attributed to the lower permeability <strong>of</strong> thecompression-wood zone, with its denser wood andmore thick-walled cells.Large micr<strong>of</strong>ibril angles are found in both compressionwood and normal wood near the pith, inducinglarger than normal longitudinal shrinkage and agreater tendency to warp. The longitudinal shrinkage<strong>of</strong> tension wood, although larger than normal wood,is less than in compression wood.<strong>36</strong>.3.1 .3 Sa wmilling Strategi esTimell (1986) describes sawmilling strategies to reducewarp in juvenile lumber and compressionwood. The cutting pattern influences the quality <strong>of</strong>drying either by releasing stresses on sawing or thecutting induces a stress pattern in the board that canbe balanced on drying. Warp has become more <strong>of</strong> aproblem with harvesting from second-growth forests<strong>of</strong> short rotation, which contain proportionatelymore juvenile wood than lumber from old-growthforests. Crook and bow are most severe in the corewood <strong>of</strong> the butt log and where compression wood isencountered; whereas twist is most severe in the corewood <strong>of</strong> the upper logs where spiral-grain angles arelarge and changing rapidly. The variation <strong>of</strong> propertiesabout the mean is the critical factor with core wood.Vá zquez (2001) examines silvicultural practiceand sawmilling strategies to counteract the effect <strong>of</strong>growth stresses in fast-grown Iberian eucalypts (Eucalyptusglobulus). A model <strong>of</strong> the stress distributionthat enables to determine the deformations on sawingis given. The appearance <strong>of</strong> checks and warps can belimited by the choice <strong>of</strong> a suitable sawing pattern, asshown in Figure <strong>36</strong>.44. Pang and Haslett (2002) notethat the residual drying stresses in quartersawnP. radiata boards are less than flatsawn boards, particularlyunder low-temperature drying conditionswhen the effect <strong>of</strong> mechanosorptive stress relief isrelatively minor. The difference in behavior is attributedto the lesser shrinkage in the width direction withquatersawn boards.<strong>36</strong>.3.2 KILN DESIGNAlthough there are differences in detail betweenmanufacturers, a lumber kiln is essentially a specialpurposeroom fitted with overhead fans for circulatingthe drying air and heating coils for maintainingthe air (and thus the wood) temperature at the setlevels. The moisture in the air is controlled by means<strong>of</strong> opening the vents in the kiln’s ro<strong>of</strong>, thus governingthe amount <strong>of</strong> moist air that returns to the fan whichis to be mixed with the fresh air drawn in. Althoughmany kilns are operated batchwise for ease <strong>of</strong> controllingthe drying conditions, which may changethrough out the drying schedule, a kiln can be continuouslyworked by arranging the lumber to beslowly railed through the chamber. In this lattercase, the drying schedule is maintained by varying thetemperature and humidity settings along the length <strong>of</strong>the kiln. There is some increase in interest in continuouskilns, which might provide energy savings andbetter quality control (McLean, 2003).The lumber is stacked externally in a rectangularpile on a low, flat-bed trolley, with rows <strong>of</strong> boardsseparated by wooden stickers <strong>of</strong> uniform thickness toprovide duct-like spaces between the boards for thekiln air to flow through. The boards may be stackedFIGURE <strong>36</strong>.44 Sawing pattern to limit the appearance <strong>of</strong> checks. (Adapted from Vázquez, M.C.T., Tensiones de crecimiento enEucalyptus globulus de Galicia (España). Influencia de la silvicultura y estrategias de aserrado (Growth stresses in E. globulusfrom Galicia (Spain). Influence <strong>of</strong> silviculture and sawing strategies), Maderas: Ciencia Tecnologia, 2(1), 68–89, 2001.)ß 2006 by Taylor & Francis Group, LLC.