36 Drying of Wood

36 Drying of Wood

36 Drying of Wood

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

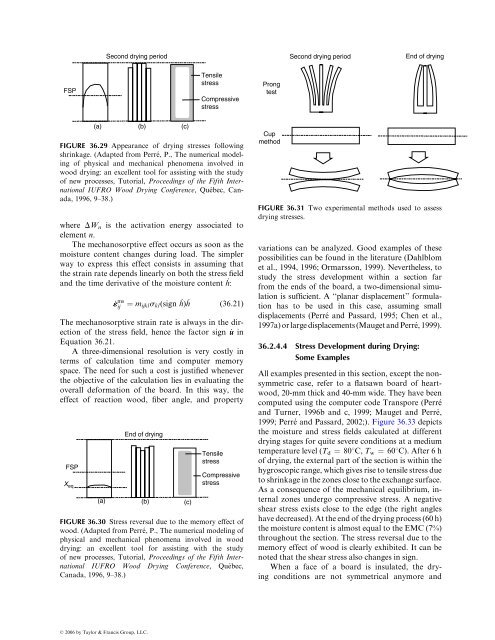

Second drying periodSecond drying periodEnd <strong>of</strong> dryingFSPTensilestressCompressivestressProngtest(a)(b)FIGURE <strong>36</strong>.29 Appearance <strong>of</strong> drying stresses followingshrinkage. (Adapted from Perré , P., The numerical modeling<strong>of</strong> physical and mechanical phenomena involved inwood drying: an excellent tool for assisting with the study<strong>of</strong> new processes, Tutorial, Proceedings <strong>of</strong> the Fifth InternationalIUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Qué bec, Canada,1996, 9–38.)where DW n is the activation energy associated toelement n.The mechanosorptive effect occurs as soon as themoisture content changes during load. The simplerway to express this effect consists in assuming thatthe strain rate depends linearly on both the stress fieldand the time derivative <strong>of</strong> the moisture content ḣ :_« msij ¼ m ijkl s kl (sign ḣ)ḣ (<strong>36</strong>:21)The mechanosorptive strain rate is always in the direction<strong>of</strong> the stress field, hence the factor sign _u inEquation <strong>36</strong>.21.A three-dimensional resolution is very costly interms <strong>of</strong> calculation time and computer memoryspace. The need for such a cost is justified wheneverthe objective <strong>of</strong> the calculation lies in evaluating theoverall deformation <strong>of</strong> the board. In this way, theeffect <strong>of</strong> reaction wood, fiber angle, and propertyFSPX eq(a)End <strong>of</strong> drying(b)(c)(c)TensilestressCompressivestressFIGURE <strong>36</strong>.30 Stress reversal due to the memory effect <strong>of</strong>wood. (Adapted from Perré, P., The numerical modeling <strong>of</strong>physical and mechanical phenomena involved in wooddrying: an excellent tool for assisting with the study<strong>of</strong> new processes, Tutorial, Proceedings <strong>of</strong> the Fifth InternationalIUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Québec,Canada, 1996, 9–38.)CupmethodFIGURE <strong>36</strong>.31 Two experimental methods used to assessdrying stresses.variations can be analyzed. Good examples <strong>of</strong> thesepossibilities can be found in the literature (Dahlblomet al., 1994, 1996; Ormarsson, 1999). Nevertheless, tostudy the stress development within a section farfrom the ends <strong>of</strong> the board, a two-dimensional simulationis sufficient. A ‘‘planar displacement’’ formulationhas to be used in this case, assuming smalldisplacements (Perré and Passard, 1995; Chen et al.,1997a)orlargedisplacements(MaugetandPerré ,1999).<strong>36</strong>.2.4 .4 Stres s Deve lopm ent dur ing Dry ing:So me Exampl esAll examples presented in this section, except the nonsymmetriccase, refer to a flatsawn board <strong>of</strong> heartwood,20-mm thick and 40-mm wide. They have beencomputed using the computer code Transpore (Perréand Turner, 1996b and c, 1999; Mauget and Perré ,1999; Perré and Passard, 2002;). Figure <strong>36</strong>.33 depictsthe moisture and stress fields calculated at differentdrying stages for quite severe conditions at a mediumtemperature level (T d ¼ 80 8C, T w ¼ 60 8C). After 6 h<strong>of</strong> drying, the external part <strong>of</strong> the section is within thehygroscopicrange,whichgivesrisetotensilestressduetoshrinkageinthezonesclosetotheexchangesurface.As a consequence <strong>of</strong> the mechanical equilibrium, internalzones undergo compressive stress. A negativeshear stress exists close to the edge (the right angleshavedecreased).Attheend<strong>of</strong>thedryingprocess(60h)the moisture content is almost equal to the EMC (7%)throughout the section. The stress reversal due to thememory effect <strong>of</strong> wood is clearly exhibited. It can benoted that the shear stress also changes in sign.When a face <strong>of</strong> a board is insulated, the dryingconditions are not symmetrical anymore andß 2006 by Taylor & Francis Group, LLC.