36 Drying of Wood

36 Drying of Wood

36 Drying of Wood

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

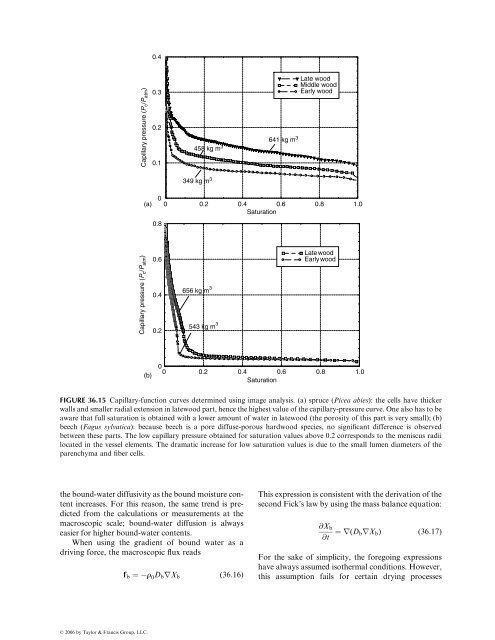

0.4Capillary pressure (P c /P atm )0.30.20.1458 kg m 3 641 kg m 3Late woodMiddle woodEarly wood349 kg m 30(a) 0 0.2 0.4 0.6 0.8 1.0Saturation0.8Capillary pressure (P c /P atm )0.60.40.2656 kg m 3543 kg m 3SaturationLate woodEarly wood(b)00 0.2 0.4 0.6 0.8 1.0FIGURE <strong>36</strong>.15 Capillary-function curves determined using image analysis. (a) spruce (Picea abies): the cells have thickerwalls and smaller radial extension in latewood part, hence the highest value <strong>of</strong> the capillary-pressure curve. One also has to beaware that full saturation is obtained with a lower amount <strong>of</strong> water in latewood (the porosity <strong>of</strong> this part is very small); (b)beech (Fagus sylvatica): because beech is a pore diffuse-porous hardwood species, no significant difference is observedbetween these parts. The low capillary pressure obtained for saturation values above 0.2 corresponds to the meniscus radiilocated in the vessel elements. The dramatic increase for low saturation values is due to the small lumen diameters <strong>of</strong> theparenchyma and fiber cells.the bound-water diffusivity as the bound moisture contentincreases. For this reason, the same trend is predictedfrom the calculations or measurements at themacroscopic scale; bound-water diffusion is alwayseasier for higher bound-water contents.When using the gradient <strong>of</strong> bound water as adriving force, the macroscopic flux readsf b ¼ r 0 D b rX b (<strong>36</strong>:16)This expression is consistent with the derivation <strong>of</strong> thesecond Fick’s law by using the mass balance equation:@X b@t¼r(D b rX b ) (<strong>36</strong>:17)For the sake <strong>of</strong> simplicity, the foregoing expressionshave always assumed isothermal conditions. However,this assumption fails for certain drying processesß 2006 by Taylor & Francis Group, LLC.