External flowDiffusion <strong>of</strong> vaporand bound waterFew vapormoleculesHeatVaporBound waterand vaporCapillary migrationMany vapormoleculesLow moisturecontent=small radiusLiquid flowHigh moisturecontent=large radiusFIGURE <strong>36</strong>.18 Second drying period: a region in the hygroscopic range develops from the exposed surface. In that region,both vapor diffusion and bound-water diffusion act. Evaporation takes place partly inside the medium. Consequently, a heatflux has to be driven toward the inner part <strong>of</strong> the board by conduction. (Adapted from Perré , P., The numerical modeling <strong>of</strong>physical and mechanical phenomena involved in wood drying: an excellent tool for assisting with the study <strong>of</strong> new processes,Tutorial, Proceedings <strong>of</strong> the Fifth International IUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Québec, Canada, 1996, 9–38.)obtain an internal overpressure, the temperature <strong>of</strong>the porous medium must be above that level during atleast one part <strong>of</strong> the process. This is the aim <strong>of</strong> convectivedrying at high temperature (moist air orsuperheated steam) and a possible aim <strong>of</strong> contactdrying or drying with an electromagnetic field (microwaveor radio frequency).However, as shown in Figure <strong>36</strong>.19, it is possibleto reduce the boiling point <strong>of</strong> water by decreasing theexternal pressure and, consequently, to obtain a hightemperatureeffect with relatively moderate dryingconditions. This is the principle <strong>of</strong> vacuum drying,particularly useful for lumber that would be damagedby high temperature levels.Whenever an overpressure exists inside a board,the large anisotropy ratios imply intricate transfermechanisms. Heat is <strong>of</strong>ten supplied in the thicknessdirection while, in spite <strong>of</strong> the length, the effect <strong>of</strong>the pressure gradient on gaseous (important for lowmoisture content) or liquid migration (important forhigh moisture content) takes place in the longitudinaldirection (Figure <strong>36</strong>.20). This is a result <strong>of</strong> the anatomicalfeatures <strong>of</strong> wood. In the case <strong>of</strong> very intensiveinternal transfer, the end piece can be fully saturatedand, sometimes, moisture can leave the sample in theliquid state. (This is quite easy to observe duringmicrowave heating.)Pressure (kPa)10050Atmospheric pressureExternal pressureBoiling temperature00 20 40 60 80 100 120Temperature (C)Saturated vaporFIGURE <strong>36</strong>.19 Vacuum drying seeks to reduce the boilingpoint <strong>of</strong> water in order to obtain a high-temperature effectwith moderate drying conditions. (saturated vapor pressurevalues from Lide 1995.)<strong>36</strong>.2.3 .3 Ty pical <strong>Drying</strong> Behavior : Differenc ebe tween Sapwood and Hear twoodIn a tree, freshly cut down and sawn, it is easy todistinguish sapwood from heartwood (by touch or bysight). But a few days later, the loss <strong>of</strong> surface moisturecontent makes it impossible to do that. Nevertheless, inß 2006 by Taylor & Francis Group, LLC.

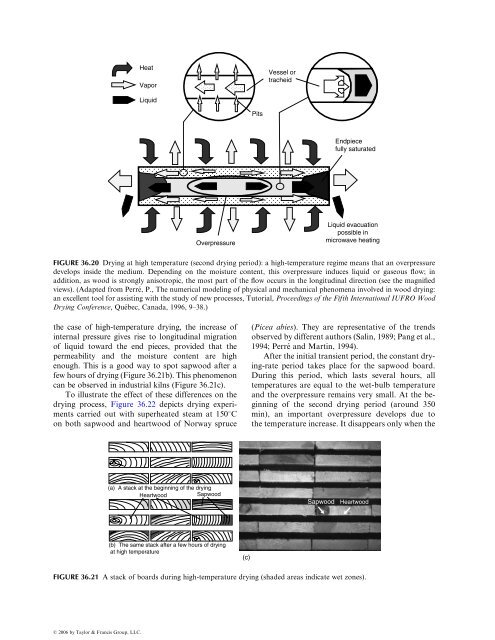

HeatVaporVessel ortracheidLiquidPitsEndpiecefully saturatedOverpressureLiquid evacuationpossible inmicrowave heatingFIGURE <strong>36</strong>.20 <strong>Drying</strong> at high temperature (second drying period): a high-temperature regime means that an overpressuredevelops inside the medium. Depending on the moisture content, this overpressure induces liquid or gaseous flow; inaddition, as wood is strongly anisotropic, the most part <strong>of</strong> the flow occurs in the longitudinal direction (see the magnifiedviews). (Adapted from Perré, P., The numerical modeling <strong>of</strong> physical and mechanical phenomena involved in wood drying:an excellent tool for assisting with the study <strong>of</strong> new processes, Tutorial, Proceedings <strong>of</strong> the Fifth International IUFRO <strong>Wood</strong><strong>Drying</strong> Conference, Québec, Canada, 1996, 9–38.)the case <strong>of</strong> high-temperature drying, the increase <strong>of</strong>internal pressure gives rise to longitudinal migration<strong>of</strong> liquid toward the end pieces, provided that thepermeability and the moisture content are highenough. This is a good way to spot sapwood after afew hours <strong>of</strong> drying (Figure <strong>36</strong>.21b). This phenomenoncan be observed in industrial kilns (Figure <strong>36</strong>.21c).To illustrate the effect <strong>of</strong> these differences on thedrying process, Figure <strong>36</strong>.22 depicts drying experimentscarried out with superheated steam at 150 8Con both sapwood and heartwood <strong>of</strong> Norway spruce(Picea abies). They are representative <strong>of</strong> the trendsobserved by different authors (Salin, 1989; Pang et al.,1994; Perré and Martin, 1994).After the initial transient period, the constant drying-rateperiod takes place for the sapwood board.During this period, which lasts several hours, alltemperatures are equal to the wet-bulb temperatureand the overpressure remains very small. At the beginning<strong>of</strong> the second drying period (around 350min), an important overpressure develops due tothe temperature increase. It disappears only when the(a) A stack at the beginning <strong>of</strong> the dryingHeartwoodSapwoodSapwood Heartwood(b) The same stack after a few hours <strong>of</strong> dryingat high temperature(c)FIGURE <strong>36</strong>.21 A stack <strong>of</strong> boards during high-temperature drying (shaded areas indicate wet zones).ß 2006 by Taylor & Francis Group, LLC.