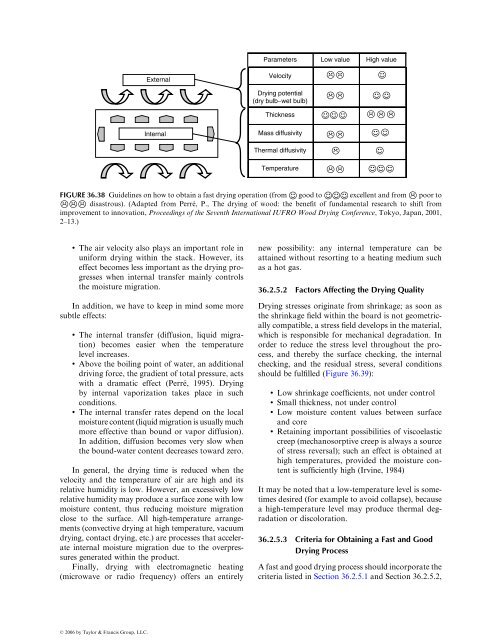

ParametersLow valueHigh valueExternalVelocity<strong>Drying</strong> potential(dry bulb−wet bulb)ThicknessInternalMass diffusivityThermal diffusivityTemperatureFIGURE <strong>36</strong>.38 Guidelines on how to obtain a fast drying operation (from good to excellent and from poor todisastrous). (Adapted from Perré, P., The drying <strong>of</strong> wood: the benefit <strong>of</strong> fundamental research to shift fromimprovement to innovation, Proceedings <strong>of</strong> the Seventh International IUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Tokyo, Japan, 2001,2–13.). The air velocity also plays an important role inuniform drying within the stack. However, itseffect becomes less important as the drying progresseswhen internal transfer mainly controlsthe moisture migration.In addition, we have to keep in mind some moresubtle effects:. The internal transfer (diffusion, liquid migration)becomes easier when the temperaturelevel increases.. Above the boiling point <strong>of</strong> water, an additionaldriving force, the gradient <strong>of</strong> total pressure, actswith a dramatic effect (Perré , 1995). <strong>Drying</strong>by internal vaporization takes place in suchconditions.. The internal transfer rates depend on the localmoisturecontent(liquidmigrationisusuallymuchmore effective than bound or vapor diffusion).In addition, diffusion becomes very slow whenthe bound-water content decreases toward zero.In general, the drying time is reduced when thevelocity and the temperature <strong>of</strong> air are high and itsrelative humidity is low. However, an excessively lowrelative humidity may produce a surface zone with lowmoisture content, thus reducing moisture migrationclose to the surface. All high-temperature arrangements(convective drying at high temperature, vacuumdrying, contact drying, etc.) are processes that accelerateinternal moisture migration due to the overpressuresgenerated within the product.Finally, drying with electromagnetic heating(microwave or radio frequency) <strong>of</strong>fers an entirelynew possibility: any internal temperature can beattained without resorting to a heating medium suchas a hot gas.<strong>36</strong>.2.5 .2 Fac tors Affecti ng the Dry ing Qual ity<strong>Drying</strong> stresses originate from shrinkage; as soon asthe shrinkage field within the board is not geometricallycompatible, a stress field develops in the material,which is responsible for mechanical degradation. Inorder to reduce the stress level throughout the process,and thereby the surface checking, the internalchecking, and the residual stress, several conditionsshould be fulfilled (Figure <strong>36</strong>.39):. Low shrinkage coefficients, not under control. Small thickness, not under control. Low moisture content values between surfaceand core. Retaining important possibilities <strong>of</strong> viscoelasticcreep (mechanosorptive creep is always a source<strong>of</strong> stress reversal); such an effect is obtained athigh temperatures, provided the moisture contentis sufficiently high (Irvine, 1984)It may be noted that a low-temperature level is sometimesdesired (for example to avoid collapse), becausea high-temperature level may produce thermal degradationor discoloration.<strong>36</strong>.2.5 .3 Cr iteria for Obtaini ng a Fast and GoodDry ing Pro cessA fast and good drying process should incorporate thecriteria listed in Section <strong>36</strong>.2.5.1 and Section <strong>36</strong>.2.5.2,ß 2006 by Taylor & Francis Group, LLC.

Second drying periodTensionParametersLow valueHigh valueCompressionThicknessTensionEnd <strong>of</strong> dryingCompressionMoisture content(bound) gradient(center−surface)ShrinkageTensionCompressionSurface moisturecontentTemperatureFIGURE <strong>36</strong>.39 Guidelines on how to obtain a good-quality product (from good to excellent and from poor todisastrous). (Adapted from Perré, P., The drying <strong>of</strong> wood: the benefit <strong>of</strong> fundamental research to shift fromimprovement to innovation, Proceedings <strong>of</strong> the Seventh International IUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Tokyo, Japan, 2001,2–13.)which are, to a large extent, contradictory. Numerousmechanisms involved during drying have to be considered(Figure <strong>36</strong>.40).Because <strong>of</strong> this complexity, compromises have tobe found. Nevertheless, some general rules can belisted (Figure <strong>36</strong>.41):. Rule 1: high relative humidit To y. ensure a lowmoisture content gradient, one way is to reducethe drying potential (wet-bulb depression) asmuch as possible. In addition, this conditionimposes a relatively high value <strong>of</strong> EMC (onlyone part <strong>of</strong> shrinkage is effected and the influence<strong>of</strong> temperature on the viscoelastic creep isnot inhibited by a relatively low moisture contentlevel). However, a high relative humidityvalue can activate the development <strong>of</strong> fungi.. Rule 2: high tem perature. A high value <strong>of</strong> temperatureis most <strong>of</strong>ten a positive factor. Thisaccelerates the internal moisture transfer andactivates the viscoelastic creep. However, careshould be taken with sensitive species; high temperaturelevels can increase the risk <strong>of</strong> collapse,problems <strong>of</strong> color, or even thermal degradation<strong>of</strong> the wood constituents.. Rule 3: high air velocity. A high air velocitypromotes good uniformity <strong>of</strong> drying throughoutthe stack. However, a higher velocity increasesthe electricity consumption and may produce,by the heat-transfer coefficient, an excessivelyhigh external transfer flux, which is opposite tothe effect intended in Rule 1.Concerning moisture transfer, Rule 1 and Rule 2meanthatinternaltransferhastobeincreasedwhereasexternal transfer should be reduced. Exceeding theboiling point <strong>of</strong> water is decisive for internal transfer.However, these rules also require the temperature tobe high with a high value <strong>of</strong> relative humidity. Suchconditions may be difficult to ensure for certaindryers. Innovative drying procedures may need newdryer designs. Finally, too <strong>of</strong>ten, the effect <strong>of</strong> temperatureand moisture content on the viscoelasticbehavior is disregarded in the optimization <strong>of</strong> dryingschedules. The situation strongly differs from onespecies to the other. Usually, s<strong>of</strong>twood species arequite easily dried. On the other hand, hardwoods are<strong>of</strong>ten intractable because <strong>of</strong> their low permeability.<strong>36</strong>.3 KILN SCALE<strong>36</strong>.3.1 LUMBER QUALITYThe ultimate fitness for the purpose <strong>of</strong> dried lumberdepends not only on the chosen drying conditions butalso on the lumber quality itself. This quality may bethought<strong>of</strong>in terms <strong>of</strong> gross defects suchas knotsaswellasintrinsicwoodpropertiessuchasthedegree<strong>of</strong>anisotropy.<strong>Drying</strong>,whichcausesanisotropicshrinkage,interactswith various wood features in various ways. Theobjective <strong>of</strong> kiln seasoning, then, is to acknowledge thisinteraction by setting process conditions that yield driedlumber to the specifications in terms <strong>of</strong> a grade for anend use. There is a world <strong>of</strong> difference between dryingdecorative hardwoods and drying structural s<strong>of</strong>twoods.Increasingly, kiln operators are drying wood fromever younger, fast-growing stands rather than from mature,old-growth forest. The drying behavior <strong>of</strong> this newkind <strong>of</strong> wood is requiring operators to adapt traditionalprocesses on the basis <strong>of</strong> better understanding <strong>of</strong> thedrying mechanism, as outlined in the previous sections.ß 2006 by Taylor & Francis Group, LLC.